A kind of preparation method of ductile iron vertical roll for tropical vertical rolling mill

A vertical roll mill and ductile iron technology, which is applied in the field of roll materials, can solve the problems of poor thermal crack resistance, anti-adhesion resistance, poor wear resistance, poor thermal conductivity and lubricating performance, and short service life, and achieve wear resistance and cold and heat. Good fatigue performance, good high temperature thermal shock and thermal crack resistance, high wear resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

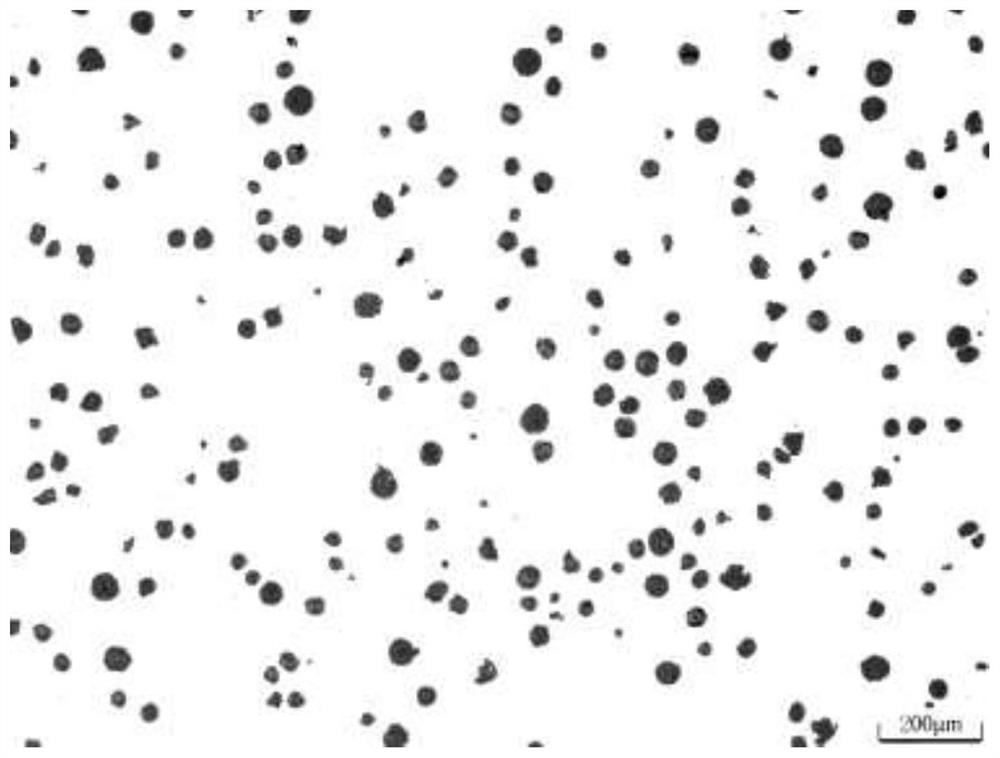

Image

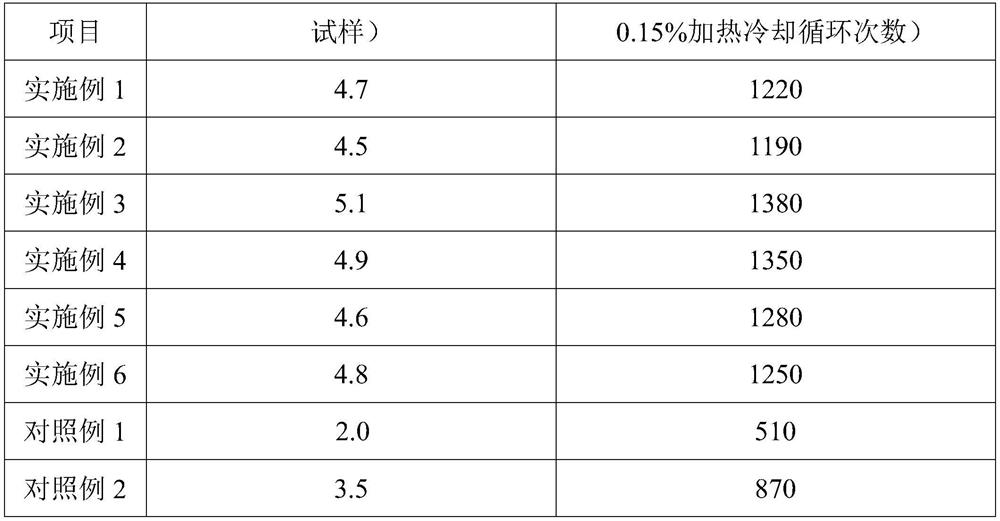

Examples

preparation example Construction

[0020] A preparation method of a ductile iron vertical roll for a tropical vertical rolling mill, comprising the following steps:

[0021] A. Using scrap steel, ferronickel, ferrovanadium, ferromolybdenum, and electrode powder as raw materials, the main component of the electrode powder is a graphitized recarburizer, and molten iron is smelted by an electric arc furnace. The melting temperature is 1400-1600 ° C. After melting Out of the furnace to get the molten iron ladle.

[0022] B. Add 0.8-1.5% rare earth magnesium nodularizing agent by weight of molten iron into the molten iron ladle obtained in step A, and the weight percentages of each component in molten iron are respectively: C: 3.0-3.8%, Si: 1.0-3.0%, Mn : 0.4-1.2%, P≤0.10%, S≤0.08%, Cr: 0.2-1.0%, Ni: 1.5-3.5%, Mo: 0.2-1.0%, the balance is Fe, cast to obtain the balls for the hot belt vertical roller mill Iron vertical roll blanks.

[0023] C. Treat the ductile iron vertical roll blank for a tropical vertical roll ...

Embodiment 1

[0025] Using scrap steel, ferronickel, ferrovanadium, ferromolybdenum, and electrode powder as raw materials, it is smelted in an electric arc furnace at a temperature of 1400 ℃. The sub-contents are: C: 3.0%, Si: 1.0%, Mn: 0.4%, P: 0.05%, S: 0.05%, Cr: 0.20%, Ni: 1.5%, Mo: 0.20%, and the balance is Fe. After pouring the ductile iron vertical roll blank for the tropical vertical roll mill, 120 hours later, the box was cold-opened. Body spray cooling, roll neck air cooling; furnace tempering at 400 ℃ for 30h.

Embodiment 2

[0027] Using scrap steel, ferronickel, ferrovanadium, ferromolybdenum, and electrode powder as raw materials, it is smelted in an electric arc furnace at a temperature of 1430 ° C. After melting, it is heated to 1540 ° C and then released to obtain a molten iron ladle, adding 1.2% of rare earth magnesium nodularizing agent, molten iron The weight percentages of each component are: C: 3.1%, Si: 2.2%, Mn: 0.5%, P: 0.06%, S: 0.06%, Cr: 0.3%, Ni: 1.8%, Mo: 0.3%, The balance is Fe. After pouring the ductile iron vertical roll blank for the tropical vertical roll mill, it was cold-opened for 130 hours, and the ductile iron vertical roll blank for the tropical vertical roll mill was heat-treated by means of integral heating. Spray cooling, roll neck air cooling; furnace tempering at 420°C for 38h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com