Self-loading and self-unloading type crawler chassis

A tracked chassis and self-unloading technology, which is applied to tracked vehicles, transportation and packaging, vehicle maintenance, etc., can solve the problems of inconvenient transition and large size of tracked chassis, and reduce transportation size, transportation cost, and hoisting work Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. The description in this part is only exemplary and explanatory, and the present invention can be implemented in many different ways defined and covered by the claims, which should not have any limiting effect on the protection scope of the present invention.

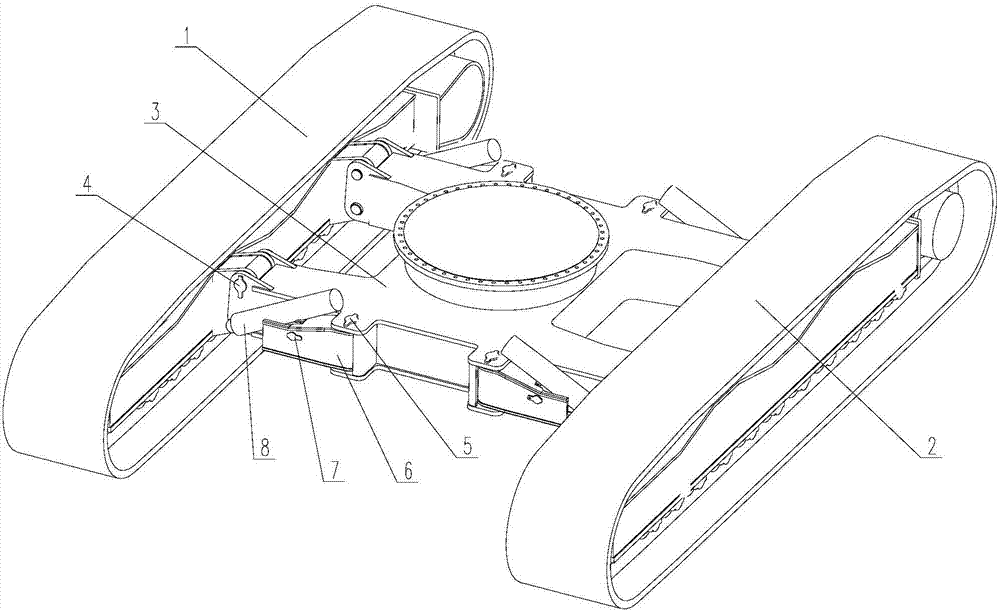

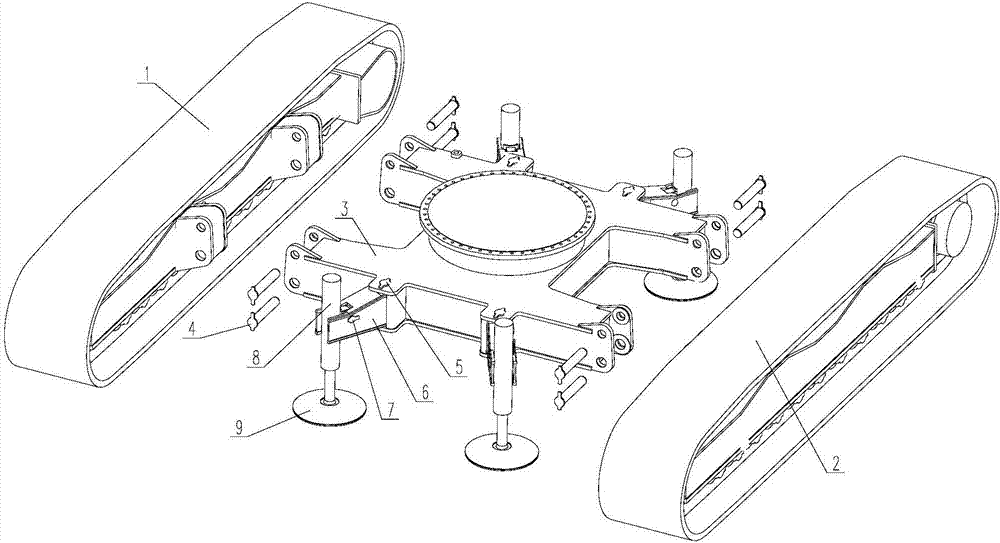

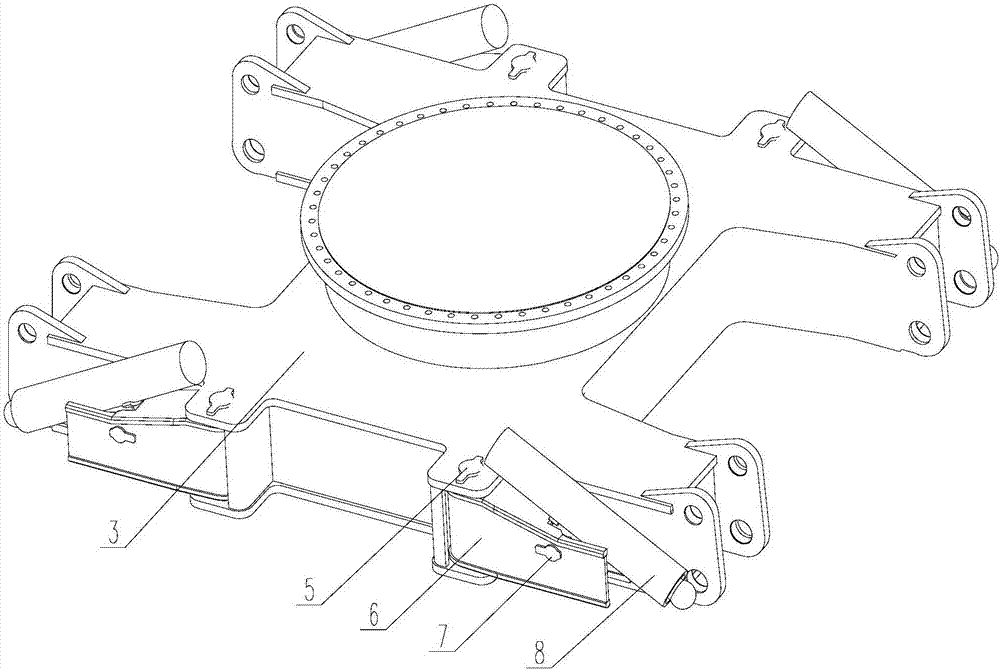

[0021] see figure 1 , when the crawler chassis works normally, the intermediate frame 3 is connected to the host structure that needs to be carried. The right crawler beam 1 and the left crawler beam 2 are respectively fixedly connected to the intermediate frame 3 through a plurality of pin shafts 4 to form a complete and workable crawler chassis. Along the two symmetrical center lines of the intermediate frame 3 , four outriggers 6 are symmetrically installed respectively, and each outrigger 6 is connected with the intermediate frame 3 through a vertical rotating shaft 5 . The supporting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com