Cloth flattening device

An expansion device and fabric technology, which is applied in the direction of thin material processing, transportation and packaging, winding strips, etc., can solve the problems of time-consuming and labor-intensive manual laying, and achieve novel structure, solve time-consuming and labor-intensive and poor effect, and easy to use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below through specific embodiments,

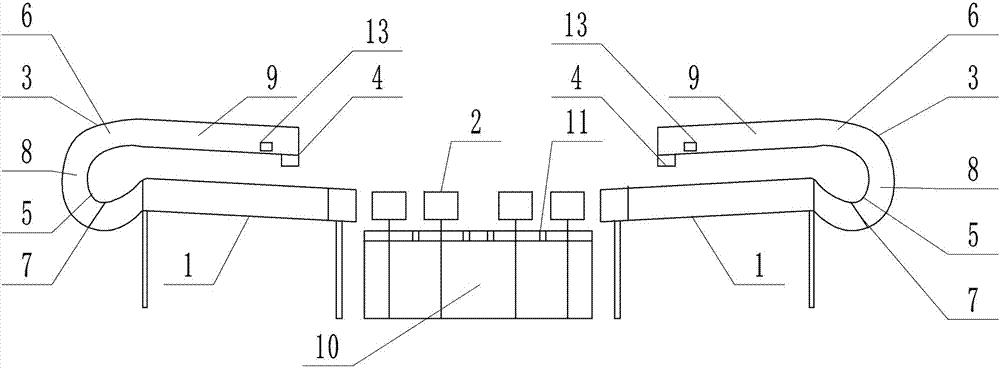

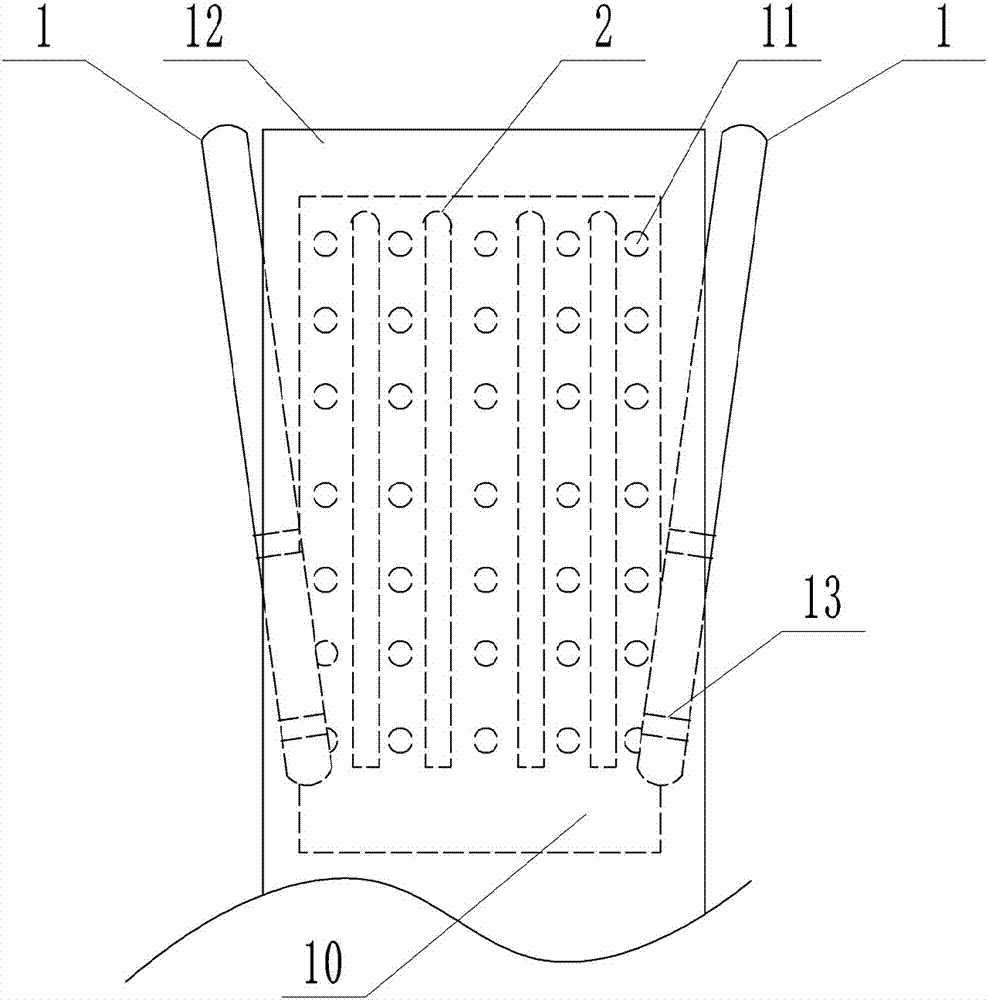

[0025] The reference numerals in the accompanying drawings of the specification include: transmission mechanism 1, cloth support plate 2, magnet recovery transmission mechanism 3, iron block outlet 4, iron block inlet 5, iron block transmission path 6, push plate 7, bending part 8, straight Section 9, steam mechanism 10, air outlet 11, cloth 12, iron block 13.

[0026] Embodiment A cloth expansion device is basically as attached figure 1 And attached figure 2 As shown, it includes two conveying mechanisms 1 arranged symmetrically. Between the two conveying mechanisms 1, there are several fabric spreaders 2 that are flush with the surface of the conveyance mechanism 1. A steam mechanism 10 is provided under the fabric spreaders 2. The steam mechanism 10 There are several air outlets 11 on the top, and the air outlets 11 are located at the corresponding positions of the gap ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com