Sewing machine

A technology for sewing machines and sewing needles, which is applied to sewing machine components, sewing equipment, cloth feeding mechanisms, etc., and can solve problems such as thread slack, hard-to-feed tooth changes, and presser foot elevation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0085] [Schematic structure of the embodiment]

[0086] Next, a sewing machine as an embodiment of the present invention will be described in detail.

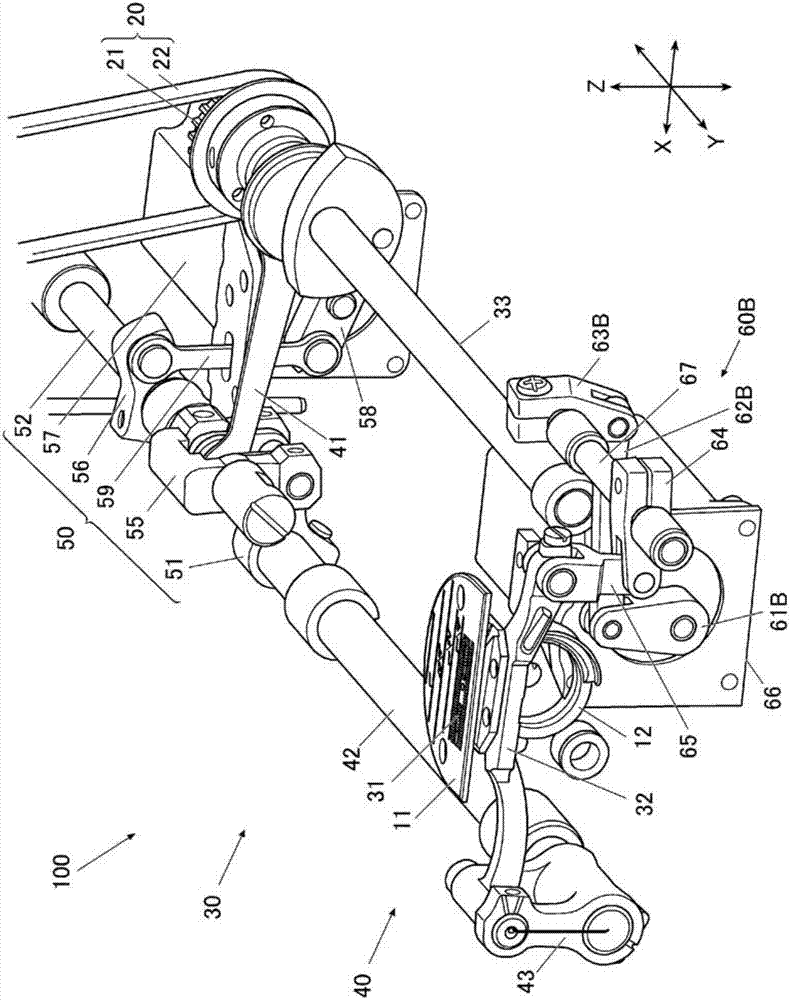

[0087] figure 1 It is a perspective view which shows the main structure inside the sewing machine base part of the sewing machine 100. FIG.

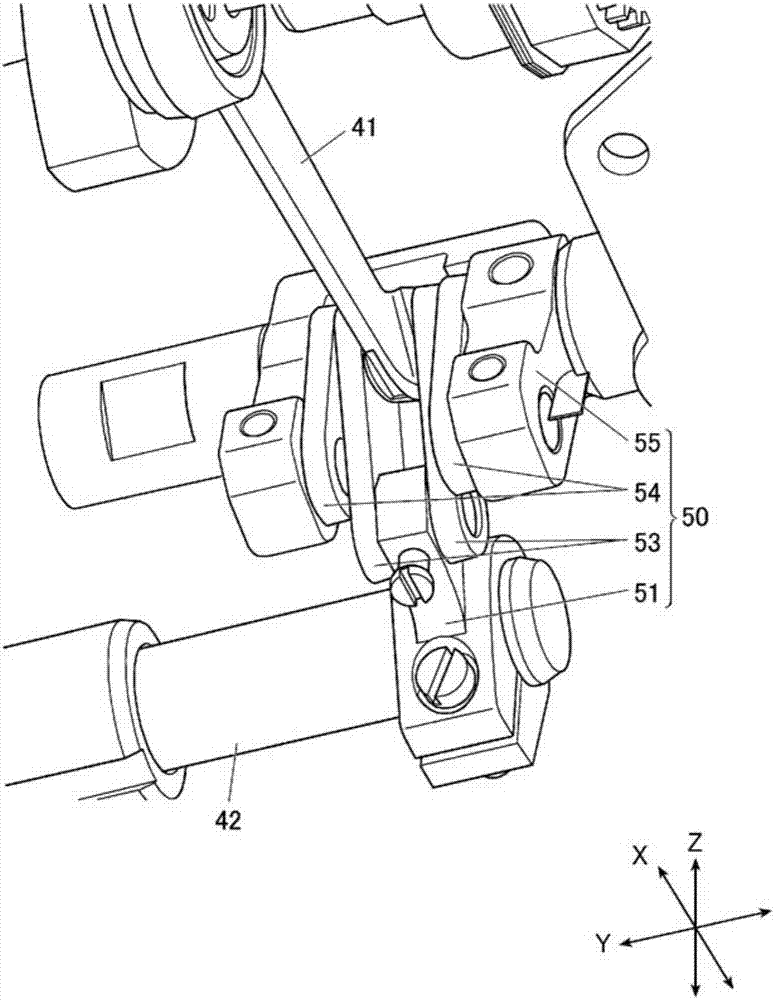

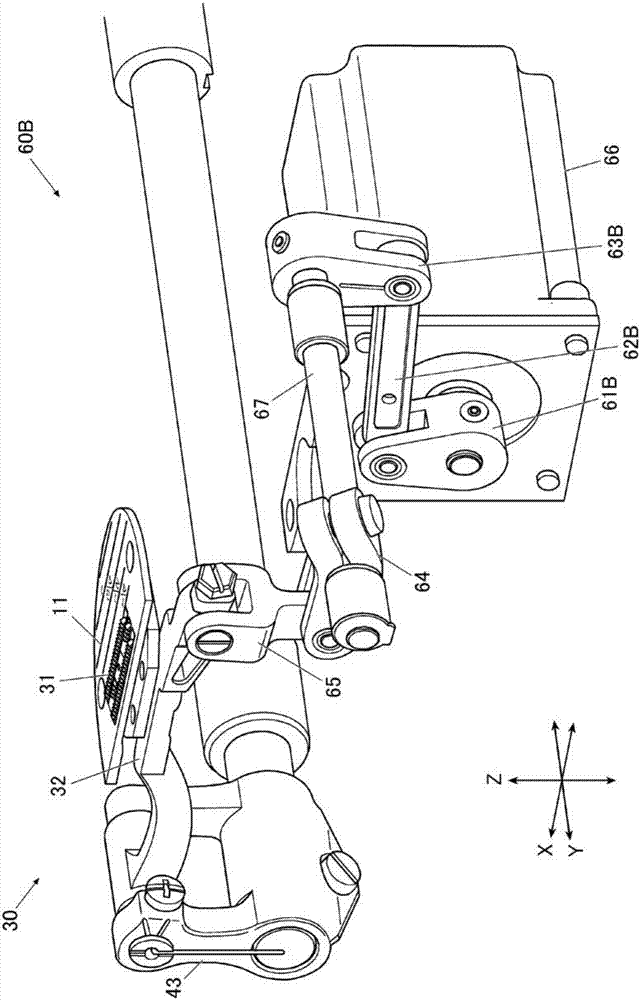

[0088] Such as figure 1 As shown, the sewing machine 100 has: a sewing needle up and down movement mechanism not shown in the figure, which moves the sewing needle up and down; the sewing machine motor 16 (refer to Figure 13 ), which becomes the driving source of the sewing needle up and down movement mechanism; the upper shaft not shown in the figure, which is rotated by the sewing machine motor 16; the kettle 12, which winds the upper thread and the lower thread; The up and down movement of the needle plate 11 correspondingly conveys the cloth as the object to be sewn; the transmission belt mechanism 20 transmits the rotational force from the upper shaft 33 of the feed device 30; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com