A Multivariable Constraint Control Method for Mounter Drive System Based on Reference Regulator

A driving system and constraint control technology, applied in the direction of control/regulation system, adaptive control, general control system, etc., can solve problems such as damage to the start-up system of the placement machine and the failure of the placement machine to work normally, so as to solve the problem of constraint control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0021] Embodiment 1: The multivariable constraint control method of the placement machine drive system based on the reference regulator includes the following steps:

[0022] Step 1. Establish a dynamic model of the drive system of the placement machine moving along the x-axis or the y-axis, express it with a state space model, and determine the constraints imposed on the drive system of the placement machine; the x-axis is horizontal, and the y-axis is vertical;

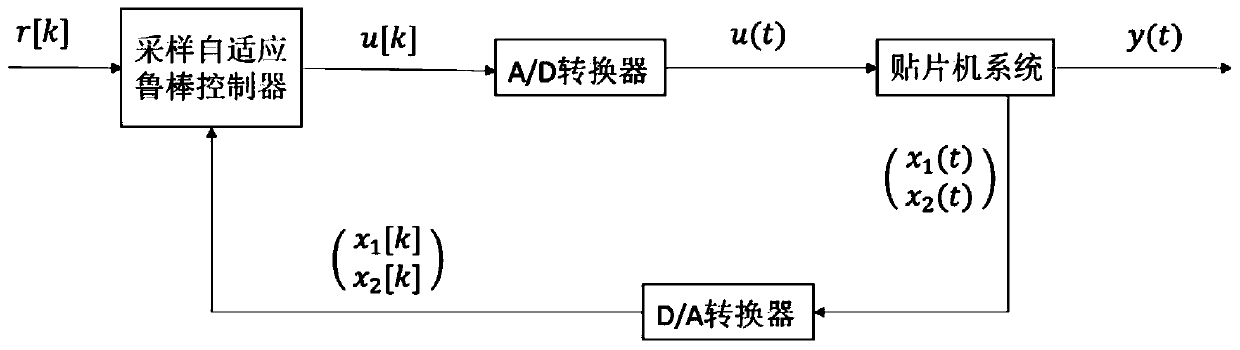

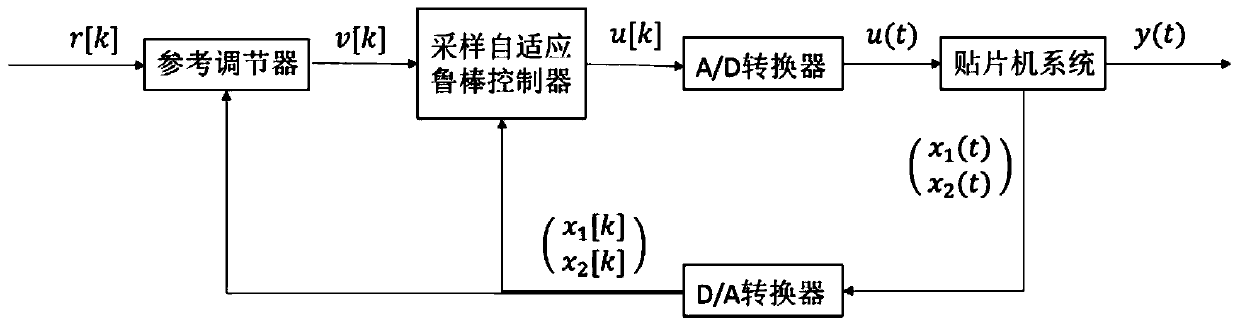

[0023] Step 2, according to the dynamic model established in step 1, design a sampling controller for the placement machine drive system;

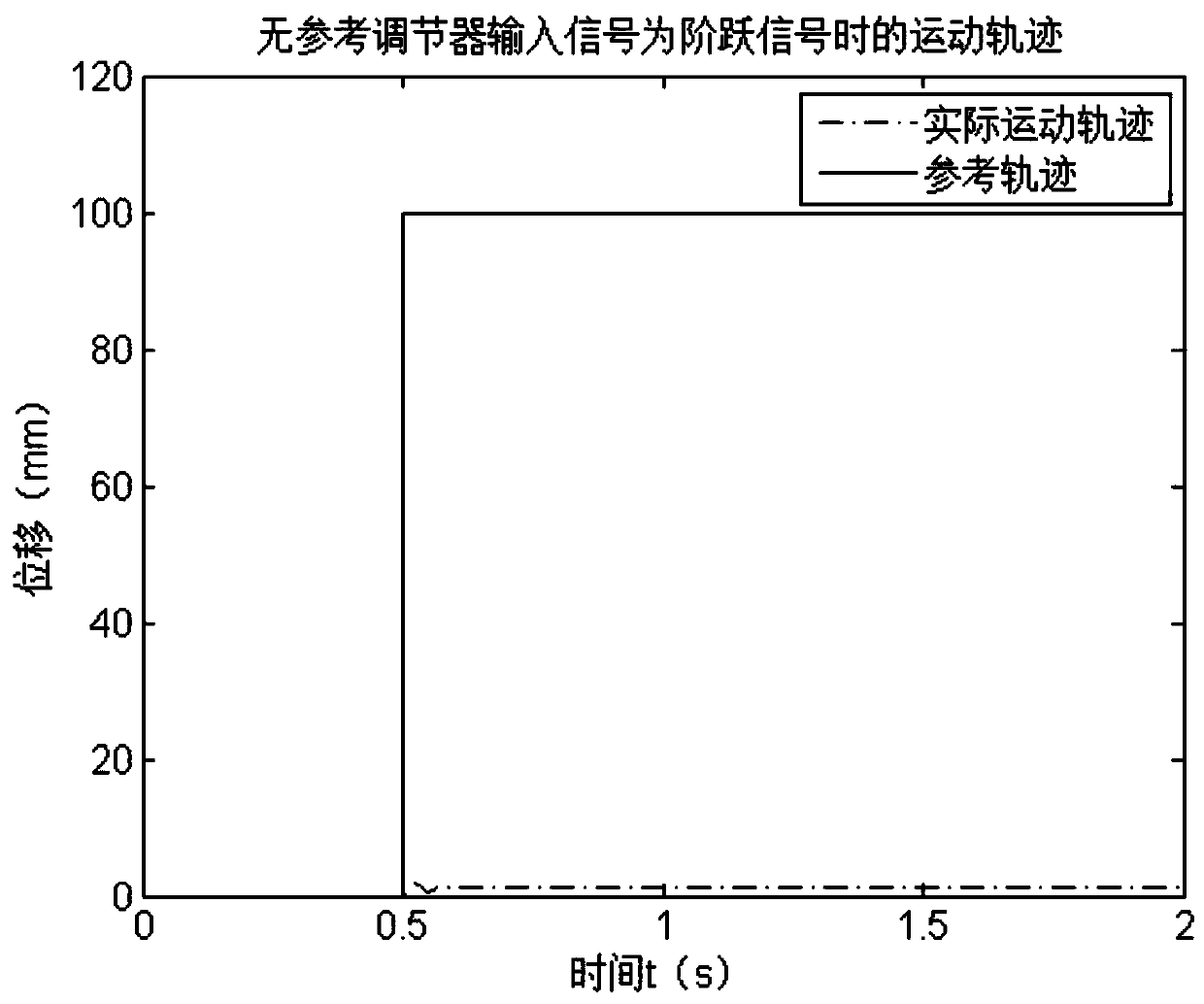

[0024] Step 3. Under the assumption that the unmodeled dynamics of the placement machine drive system and the external disturbance are constant values, predict the state of the placement machine drive system and the size of the control input when the reference signal does not change; the placement machine drive The state of the system includes the displacement and velocity of th...

specific Embodiment approach 2

[0027] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in the step 1, a dynamic model of the drive system of the chip mounter is established along the x-axis or y-axis, represented by a state space model, and the patcher is determined. The specific process of the constraint conditions of the machine-driven system is as follows:

[0028] Ignoring the positioning force and Coulomb friction force when the patch motorized platform moves, according to Newton's second law, establish the dynamic equation when the patch motorized platform moves along the x-axis or y-axis direction, and determine the patch by the method of least squares identification Uncertainty parameters M and B of the machine-driven system, and bounds for external disturbances or unmodeled dynamics:

[0029]

[0030] where M≈11kg∈[θ 1min , θ 1max ]=[10kg,15kg] is the mass of the patch motorized platform, θ 1min and θ 1max are the upper and lower bounds of M, re...

specific Embodiment approach 3

[0036] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that: in the step two, according to the dynamic model established in step one, the specific process of designing the sampling controller for the drive system of the placement machine is as follows:

[0037] Design an adaptive sampling controller for the system as:

[0038]

[0039] in Denotes kT moment θ 1 the estimated value of Denotes kT moment θ 2 the estimated value of is a virtual sampling control law, the position of the patch maneuvering platform at time kT is x 1 [k], the position error is z 1 [k]=x 1 [k]-r[k], speed is x 2 [k], the speed difference is z 2 [k]=x 2 [k]-α 1 [k], r[k] is the sampling input signal, T is the sampling time, k 1 、k 2 >0 is the controller parameter, is the robust item in the controller, ε is used to adjust and sgn(h[k]·z 2 The parameters of the error size between k), tanh represents the hyperbolic tangent func...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com