Uni and bi-direction power load counterweight resistance element device

A dynamic load and resistance technology, applied in the direction of electromechanical devices, sports accessories, electrical components, etc., can solve the problems of operator injury and safety hazards, and achieve the effects of improving integrity, adjustable damping effect, and significant damping buffer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

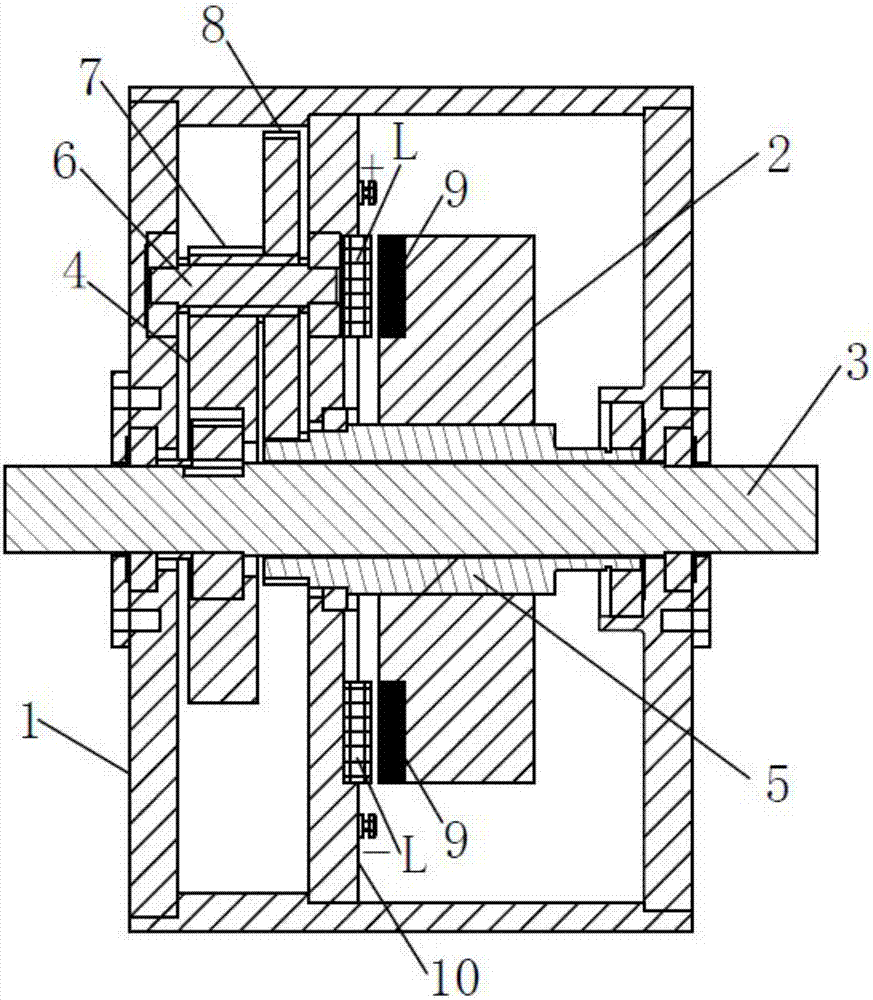

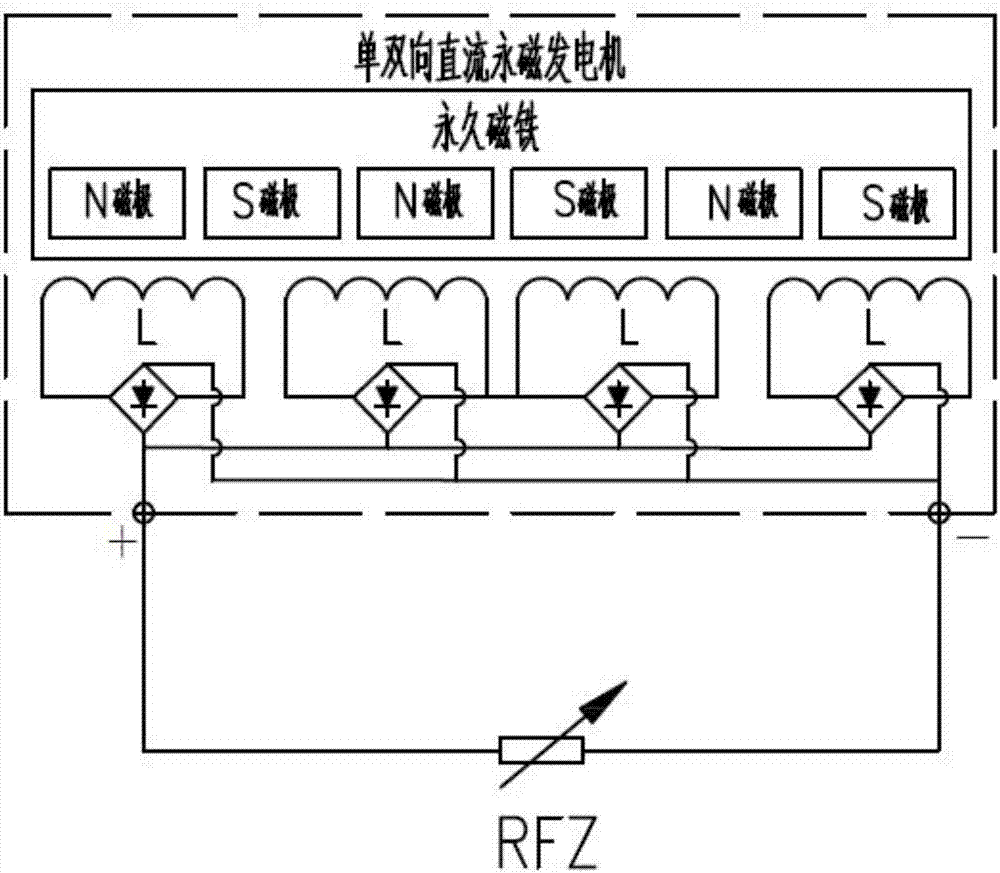

[0021] Depend on figure 1 , 2 It can be known from the embodiment shown in and 4 that this embodiment includes a transmission component support body 1, a gear transmission connection structure and at least one damping counterweight 2, and the gear transmission connection structure includes a drive gear shaft and a drive gear shaft for axially fixed connection with the damping action shaft. The gear transmission part, the driving gear shaft includes the driving shaft 3 and the driving gear 4, the driving gear 4 is fixed on the driving shaft 3, the driving gear shaft and each gear transmission parts are respectively supported on the transmission part support body 1 through bearings, and the driving gear 4 It forms a gear meshing transmission connection with each gear transmission part. The gear transmission part at the end of the gear transmission connection structure is connected to the damping weight 2 gear meshing transmission connection. The damping weight 2 is a rotating bo...

Embodiment 2

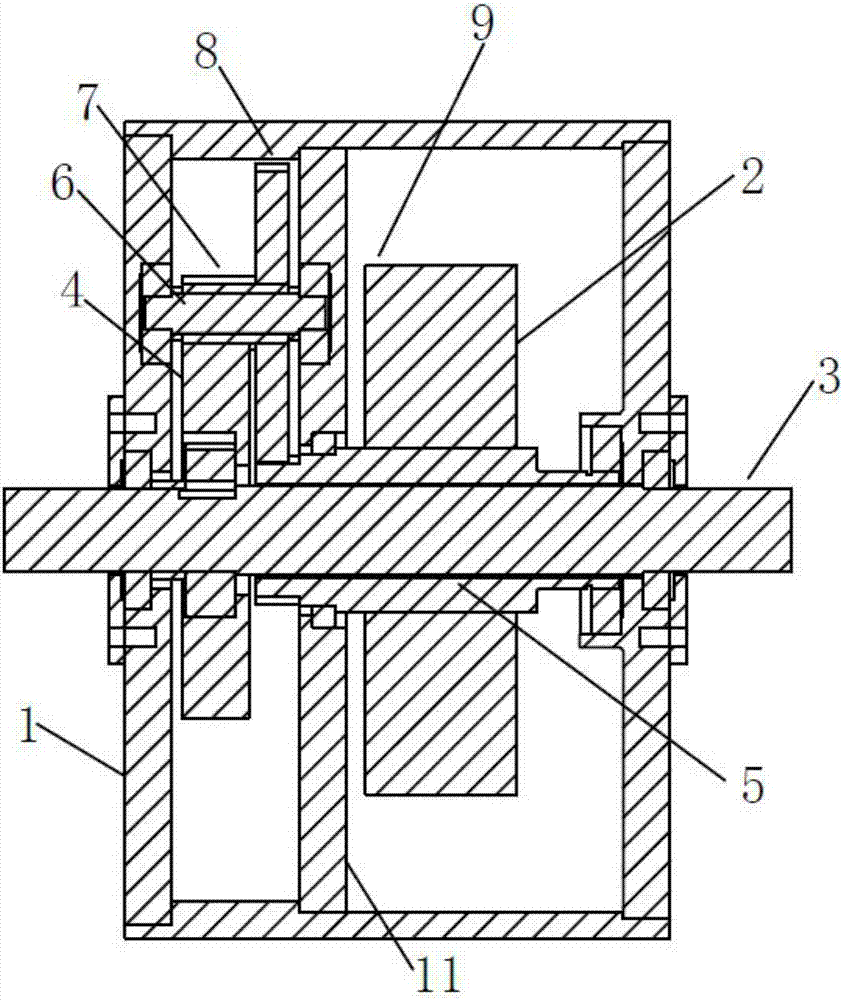

[0029] Depend on image 3 and 4It can be seen from the illustrated embodiment that this embodiment includes a transmission component support body 1, a gear transmission connection structure and at least one damping counterweight 2, and the gear transmission connection structure includes a drive gear shaft and a gear transmission shaft for axially fixed connection with the damping shaft. Components, the driving gear shaft includes a driving shaft 3 and a driving gear 4, the driving gear 4 is fixed on the driving shaft 3, the driving gear shaft and each gear transmission part are respectively supported on the transmission part support body 1 through bearings, and the driving gear 4 and each A gear meshing transmission connection is formed between the gear transmission parts, and the gear transmission part at the end of the gear transmission connection structure is connected to the gear meshing transmission connection of the damping weight 2, the damping weight 2 is a rotating bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com