Multi-component hybrid damping composite material and preparation method

A technology of composite materials and hybrid materials, applied in the field of engineering materials preparation, to achieve good mechanical properties, good impact resistance, and excellent vibration reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

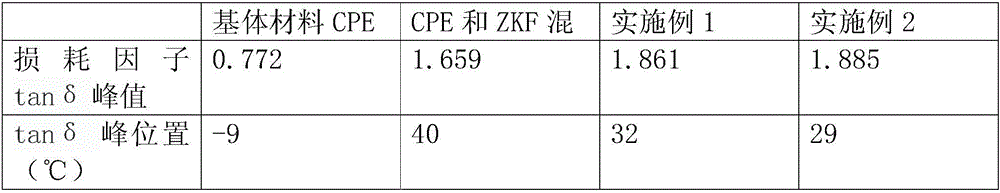

Examples

Embodiment 1

[0018] Two layers of hybrid materials are used to construct the multi-component hybrid anti-damping composite material. The mass ratio of each component of the multi-component hybrid adopts CPE:ZKF:EBP:PC=60:32:6:2, CPE and the first layer of multi-component hybrid The volume percentage of the body is 60:40,

[0019] Prepare multivariate hybrids:

[0020] 1) Preparation of PC (polycarbonate), heating polycarbonate to 150-160°C to obtain polycarbonate in molten state, set aside;

[0021] 2) Take the CPE powder and add it to the molten PC obtained in step 1), and stir evenly, then naturally cool to room temperature to obtain a complex, and then put the complex into the liquid nitrogen upper space in the liquid nitrogen pool at -160°C, Keep warm for 15 minutes, take it out, crush and grind to get powder, set aside;

[0022] 3) Put the powder obtained in step 2) into the roller and knead for 5 minutes, then add ZKF and mix with a cutter, knead for 15 minutes, after kneading even...

Embodiment 2

[0026] The three-layer hybrid material is used to construct the multi-component hybrid anti-damping composite material. The mass ratio of each component of the multi-component hybrid adopts CPE:ZKF:EBP:PC=60:32:6:2, and the CPE and the first layer of multi-component hybrid The volume percentage of the hybrid body and the second-layer multi-component hybrid body is 60:30:10.

[0027] Prepare multivariate hybrids:

[0028] 1) Preparation of PC (polycarbonate), heating polycarbonate to 150-160°C to obtain polycarbonate in molten state, set aside;

[0029] 2) Take the CPE powder and add it to the molten PC obtained in step 1), and stir evenly, then naturally cool to room temperature to obtain a complex, and then put the complex into the liquid nitrogen upper space in the liquid nitrogen pool at -160°C, Keep warm for 15 minutes, take it out, crush and grind to get powder, set aside;

[0030] 3) Put the powder obtained in step 2) into the roller and knead for 5 minutes, then add Z...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com