Anti-dust device for furniture production

A dust-proof device and furniture technology, which is applied in the direction of combined devices, dispersed particle separation, chemical instruments and methods, etc., can solve problems affecting the working environment of the workshop, large dust, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

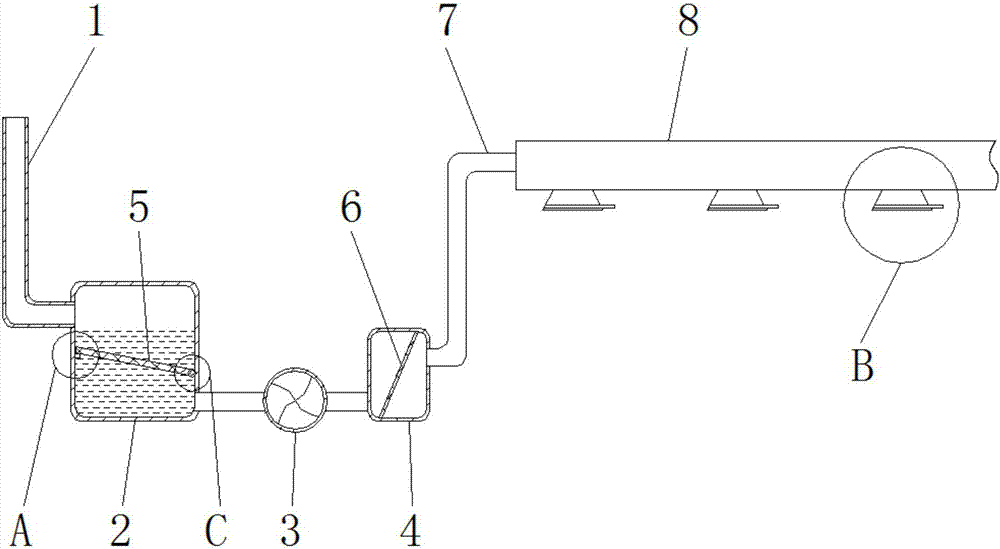

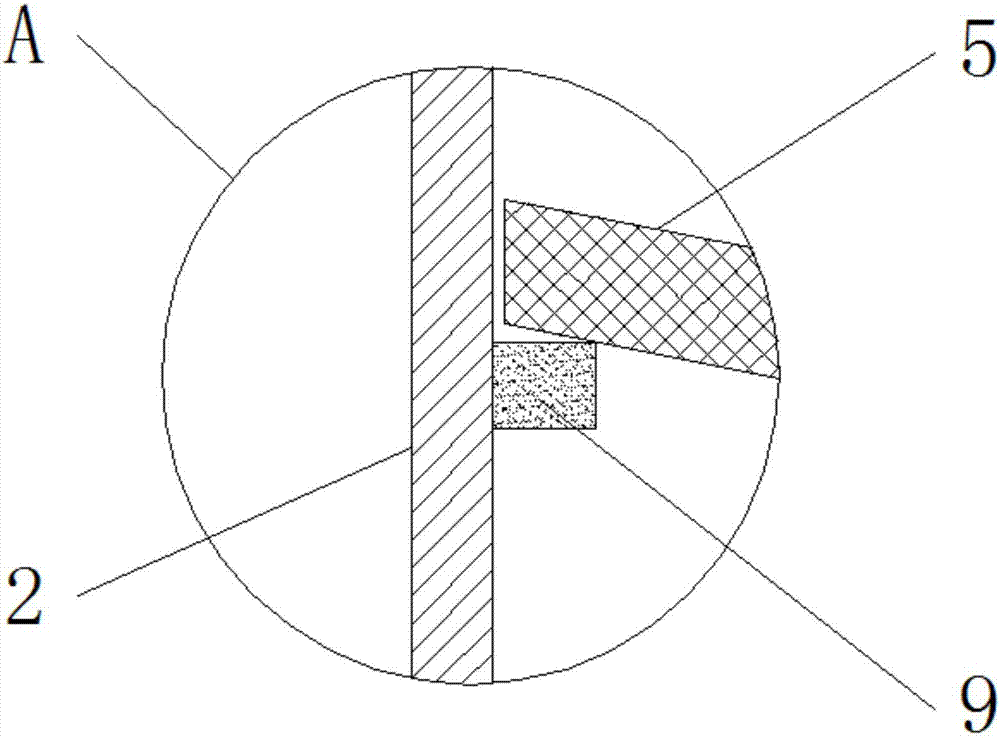

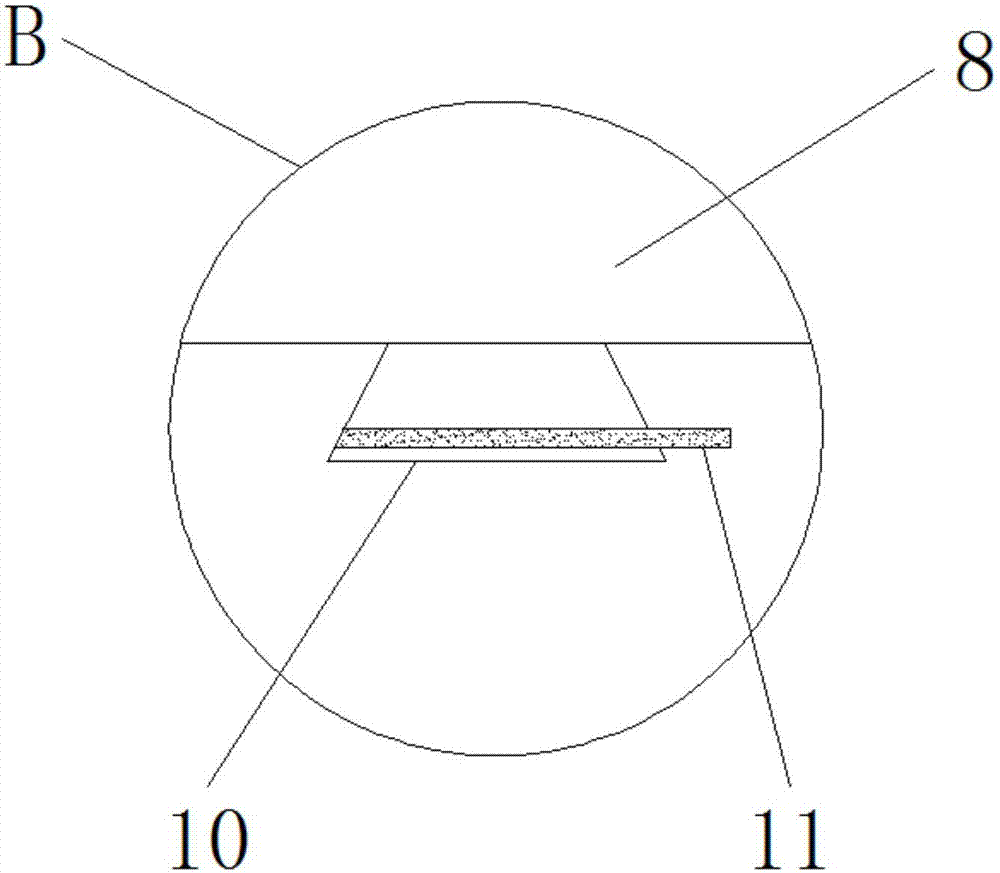

[0019] like Figure 1-Figure 5 As shown, a dust-proof device for furniture production mainly includes an exhaust pipe 1, a fan 3, a second mesh plate 6, a bump 9 and a smoking port 10, the exhaust pipe 1 is arranged at the left end of the water tank 2, and the water tank 2 The inside of the first net plate 5 is connected with the first net plate 5 through the rotating hinge 12. The structure of the first net plate 5 is a rotating structure, and the rotation angle range of the first net plate 5 is 0-80°. The rotating hinge 12 is set to make the second net plate 5 The rotation and opening of a net plate 5 is beneficial to cleaning the inside of the water tank 2. The structure of the first net plate 5 is the same as that of the second net plate 6, and the mesh aperture of the first net plate 5 is smaller than that of the second net plate 6 mesh apertures, the first mesh plate 5 is set to make the gas with dust fully contact with water, so that the dust in the air is deposited at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com