Injection molding die finishing outer side arc core drawing through swinging block mechanism and application method of injection molding die

A technology of injection molds and arcs, applied in the field of injection molds, to achieve the effects of reliable work, cost reduction, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings, but the present invention is not limited thereto.

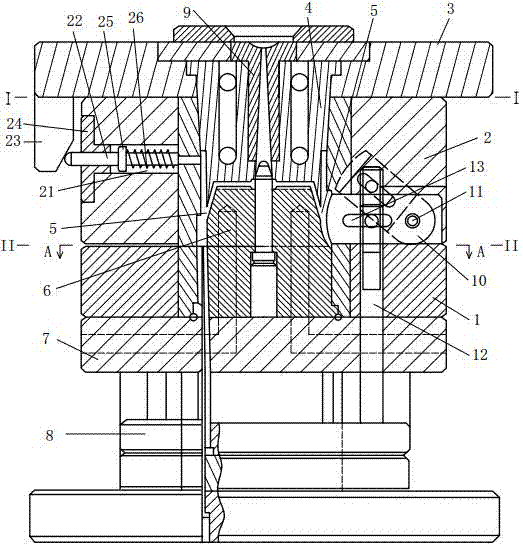

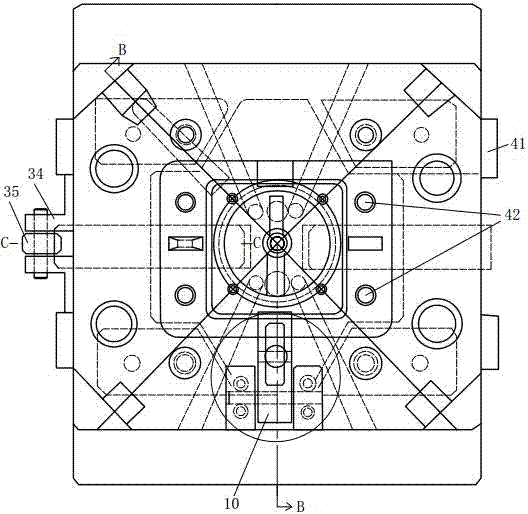

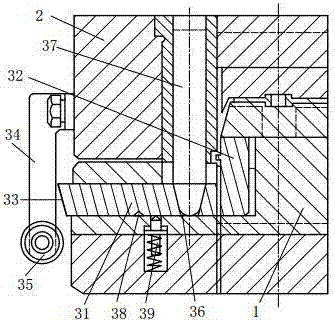

[0026] refer to Figure 1 to Figure 3

[0027] An injection mold that uses a pendulum mechanism to complete outer arc core pulling, comprising a movable template 1 arranged on a mold frame, a fixed template 2 and a fixed template 3 installed on the fixed template, the fixed template A fixed mold core 4 extending into the fixed template is installed, and a movable mold core 6 extending into the fixed template and cooperating with the fixed template and the fixed mold core to form a workpiece cavity 5 is fixed on the movable template, and the lower part of the fixed template is arranged A pendulum block 10 with an inner end extending into the cavity of the workpiece to form an arc undercut on the outer surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com