A foundation grouting operation system for offshore wind turbines

A technology for foundation grouting and operation system, which is applied in the field of foundation grouting operation system for offshore wind turbines, can solve the problems of difficult operation, tight construction time, and inability to adapt to offshore platforms.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific examples.

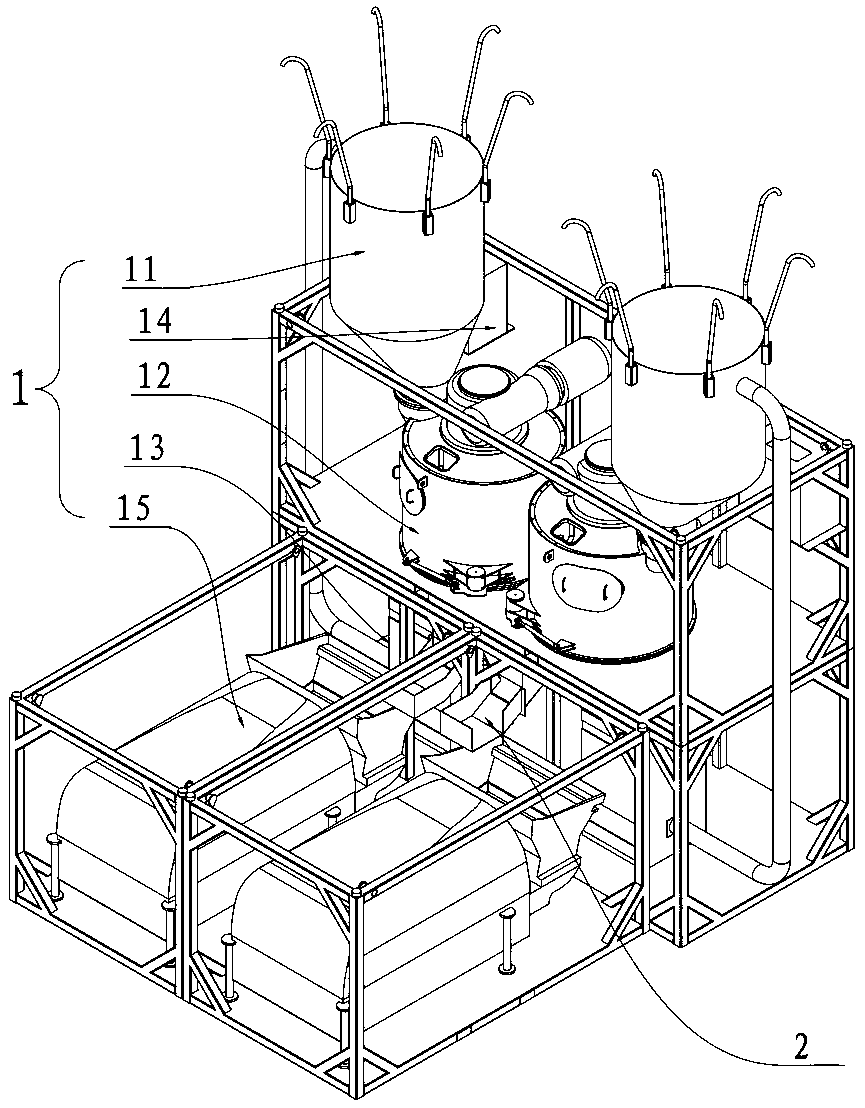

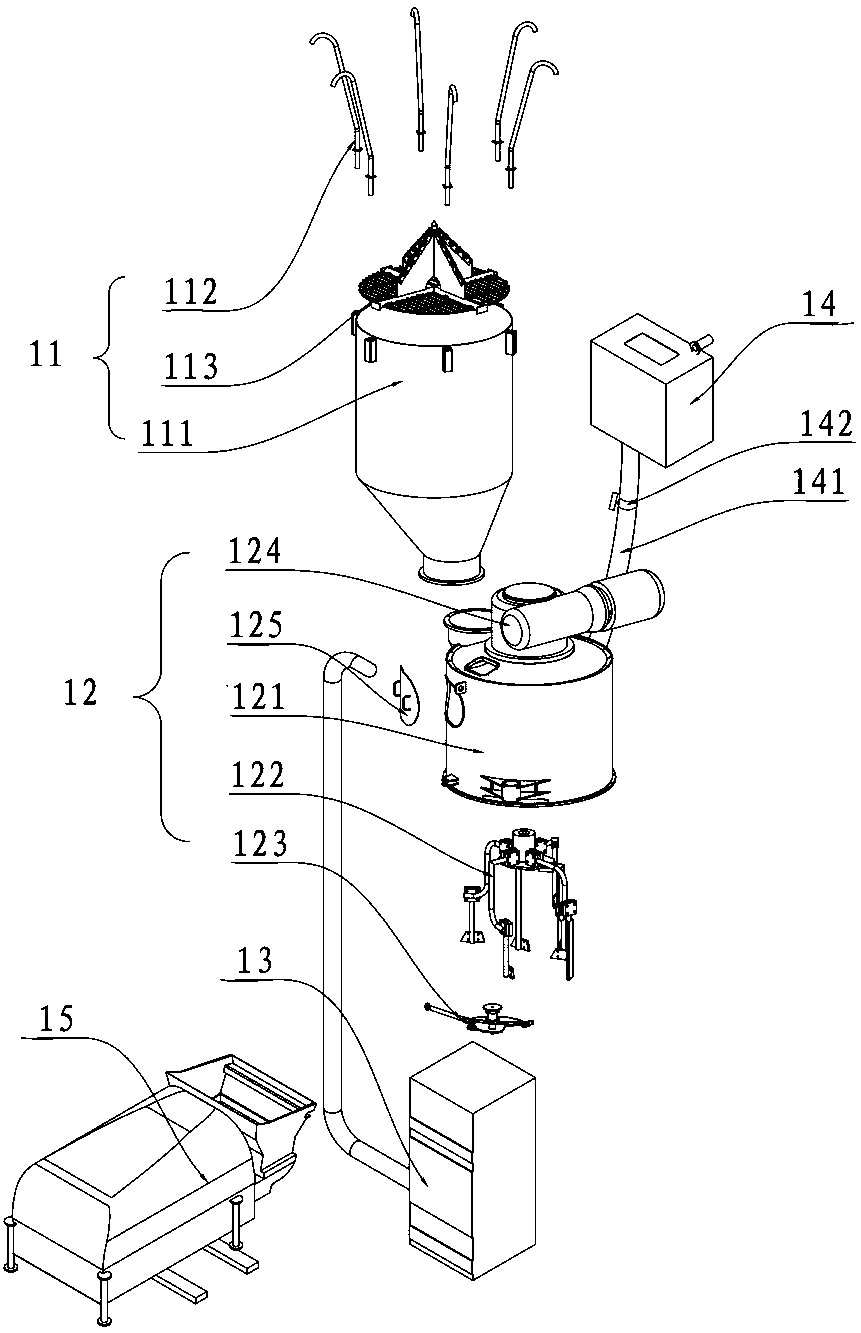

[0018] See attached figure 1 to attach Figure 8 As shown, in this embodiment, an offshore wind turbine foundation grouting operation system includes two groups of grouting devices 1 symmetrically arranged on the frame and a group of discharge mechanisms 2; each group of grouting devices 1 includes a feed Mechanism 11, stirring mechanism 12, vacuum cleaner, elevated water tank and mortar pump.

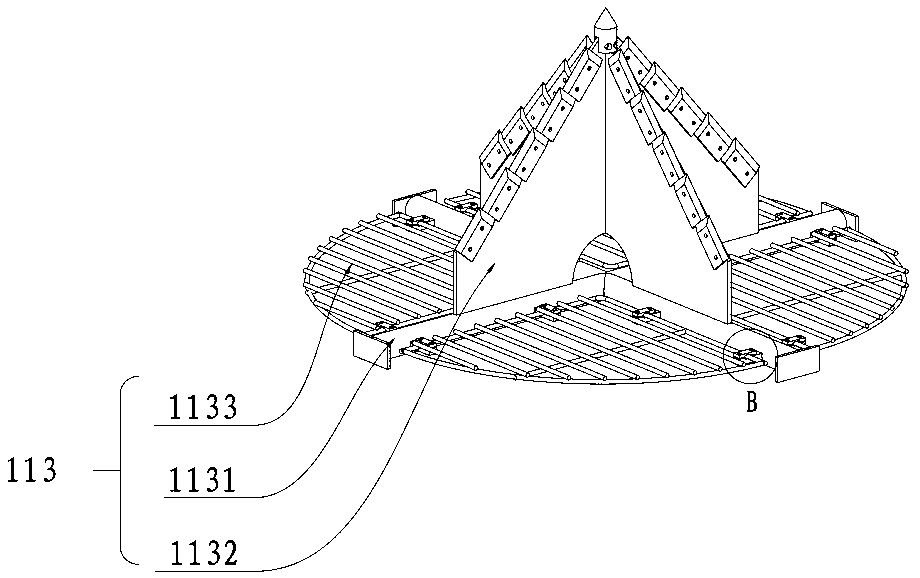

[0019] In this embodiment, the feeding mechanism 11 includes a feeding tank 111, an unpacking assembly 113 arranged in the feeding tank 111, and six guide rods 112 annularly arranged on the outer surface of the feeding port of the feeding tank 111 , wherein, the six material guide rods 112 are in the shape of a bell mouth, and the material bag can be more accurately aligned with the feed inlet of the feed tank 111 by being provided with the feed guide rods 112, so as to avoid the occ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com