Evaluation method for bonding strength of drainage asphalt mixture joint

A drainage asphalt and evaluation method technology, applied in the direction of testing material strength by applying stable bending force, testing material strength by applying stable tension/pressure, etc., can solve loose, large gaps in joints, and no bonding force at joints An effective test method and other issues to achieve the effect of high feasibility and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] S1: According to the asphalt ratio and gradation design of the porous asphalt mixture, according to the T 0703-2011 rutting plate manufacturing method in the "Test Regulations for Asphalt and Asphalt Mixtures in Highway Engineering JTG E20-2011", indoor mixing is used to produce drainage asphalt mixture and molding test parts; the design gradation and oil stone ratio used are shown in Table 1.

[0040] Table 1 Mixture design gradation, asphalt ratio

[0041]

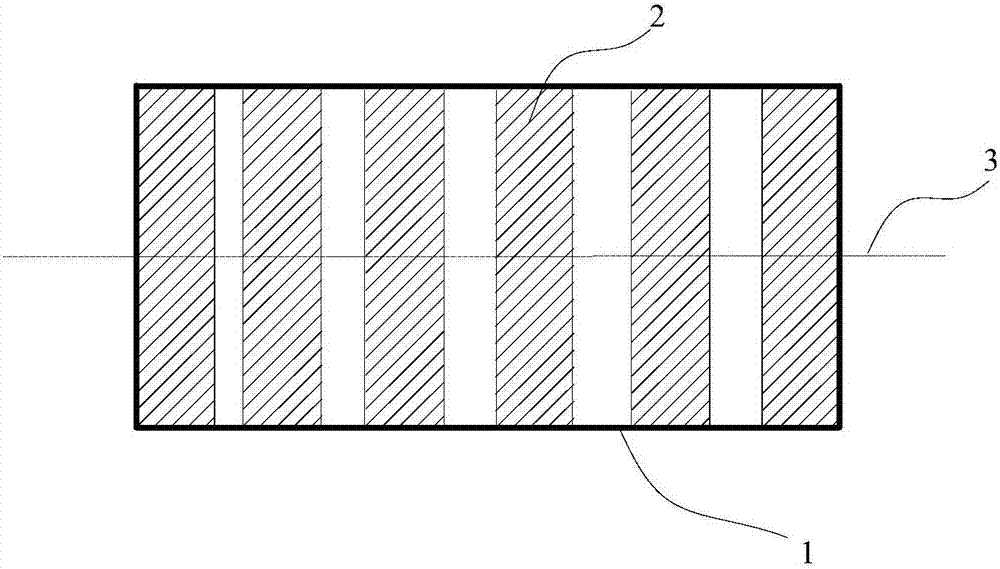

[0042] Mix and produce drainage asphalt mixture, use a mold with a length, width and height of 300×300×50mm, and roll it into shape, see figure 1 , formed into a plate-shaped rutting test piece 1, marking the upward side of the test piece in the mold;

[0043] S2: the rut test piece formed by S1 is cut along the rolling direction, and the cutting position 3 of the rut test piece is the direction of travel of the wheel during rolling; cut into two half test pieces equal in area;

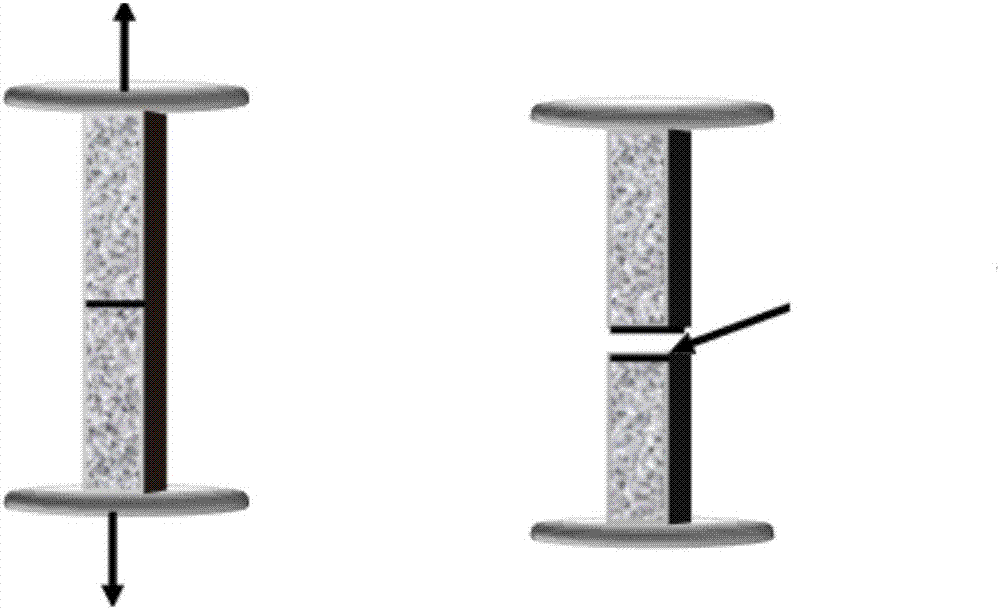

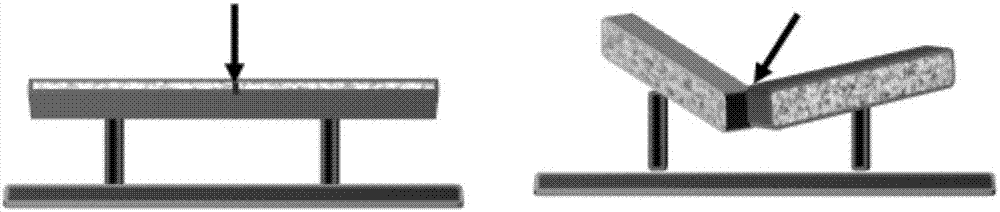

[0044] S3: Take a half of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com