Method for testing and evaluating properties of bonding layer of asphalt pavement

A kind of asphalt pavement and evaluation method technology, which is applied in the direction of measuring devices, instruments, and mechanical devices, etc., can solve the problem that there is no effective test method for the interlayer adhesion of drainage asphalt pavement surface layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

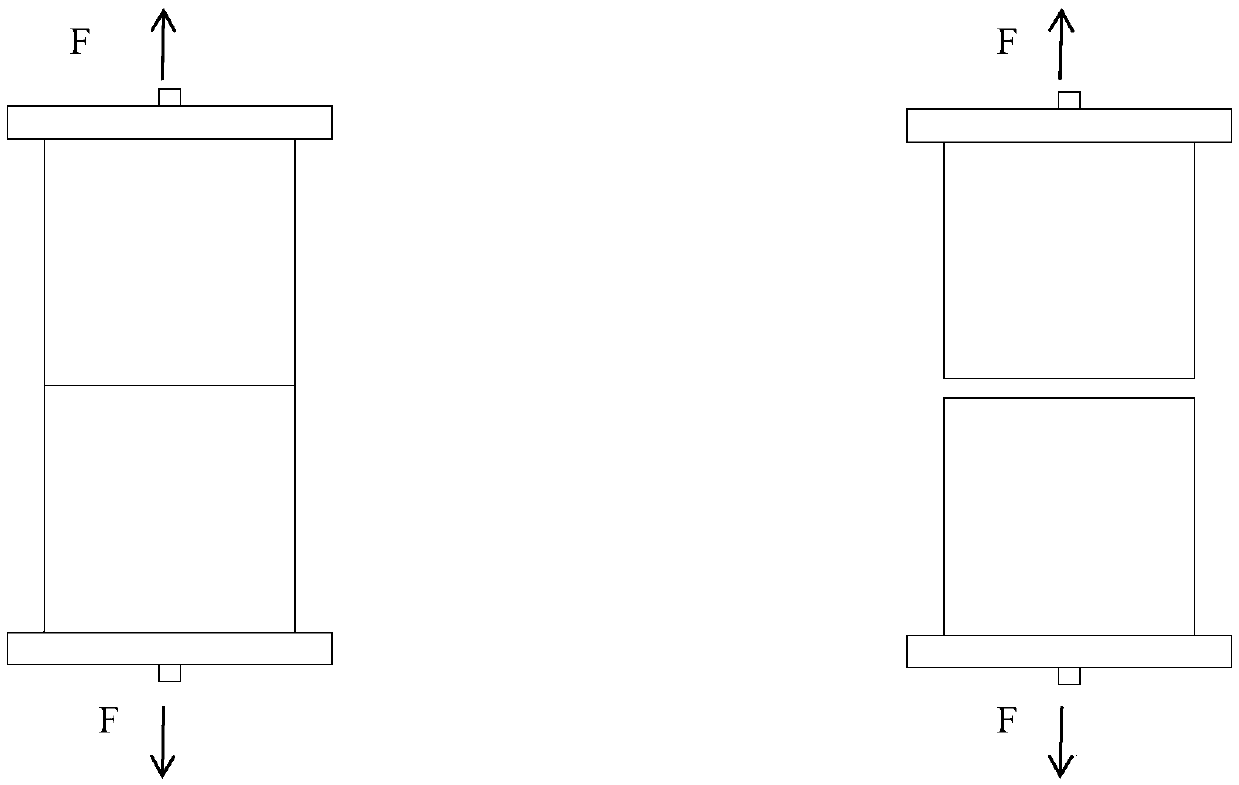

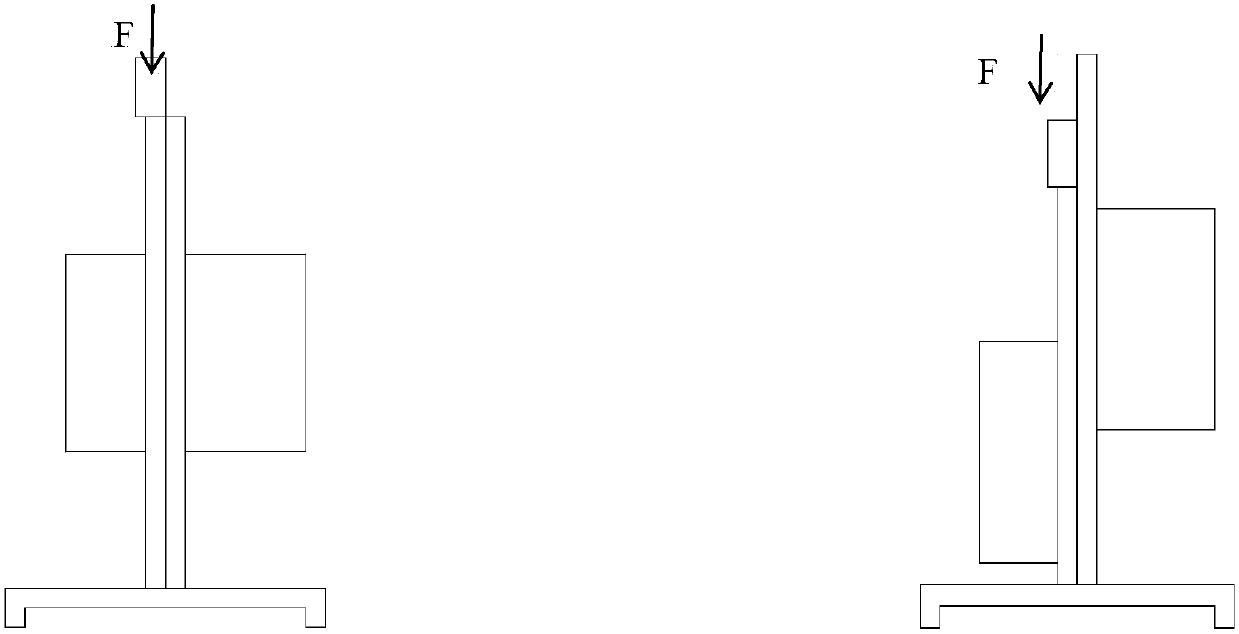

Method used

Image

Examples

Embodiment 1

[0039] This embodiment is based on the 2015 Ningjing Salt Drainage Asphalt Pavement Interlayer Bonding Material Selection Project in Jiangsu Province, and the present invention is applied to detect the rubber asphalt synchronous crushed stone seal layer bonding layer material combined with a variety of different materials, and a preferred one is selected. A combination of one or more effective drainage asphalt pavement adhesive course materials.

[0040] Table 1 Structural composition of drainage asphalt pavement

[0041]

[0042] 40mmPAC means 40mm thick, porous asphalt mixture (Porous Asphalt Concrete). AC-20 means asphalt mixture, in which the nominal maximum particle size of the aggregate is 19.0mm. I indicates the type of compound.

[0043] This implementation case is a test and evaluation of rubber asphalt synchronous crushed stone seal layer bonding layer materials combined with various materials in the test section of the road maintenance in Huaiyin District, Jian...

Embodiment 2

[0059] Based on the drainage type asphalt concrete overlay project of Ningsu-Xu Expressway in 2016, the cohesion between the core samples of the new pavement was analyzed and verified.

[0060] In this embodiment, a set of core samples includes core samples taken from three locations, namely, the right wheelmark of the driving lane, the right wheelmark of the overtaking lane, and the right wheelmark of the emergency lane. Other steps are with embodiment 1.

[0061] Table 3 Structural composition of Ningsuxu drainage pavement

[0062]

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com