Butterfly cable

A technology of butterfly optical cable and optical cable, which is applied in the field of optical cable production, can solve the problems of hydrogen loss of optical fiber, reduce the service life of optical fiber, and weak ability to protect optical fiber, and achieve the effects of increasing mechanical strength, improving shock absorption performance, and facilitating fixing of optical cable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

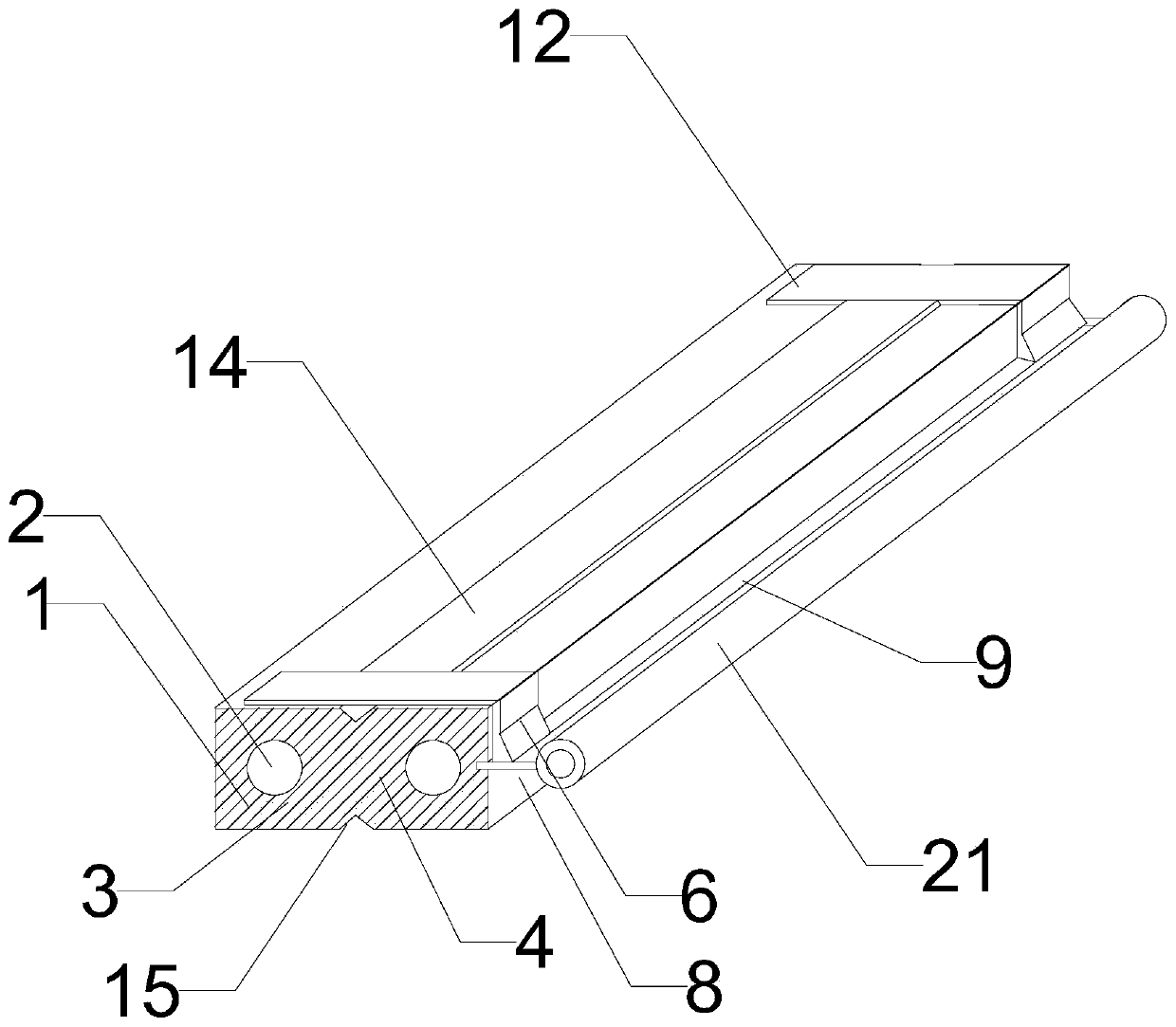

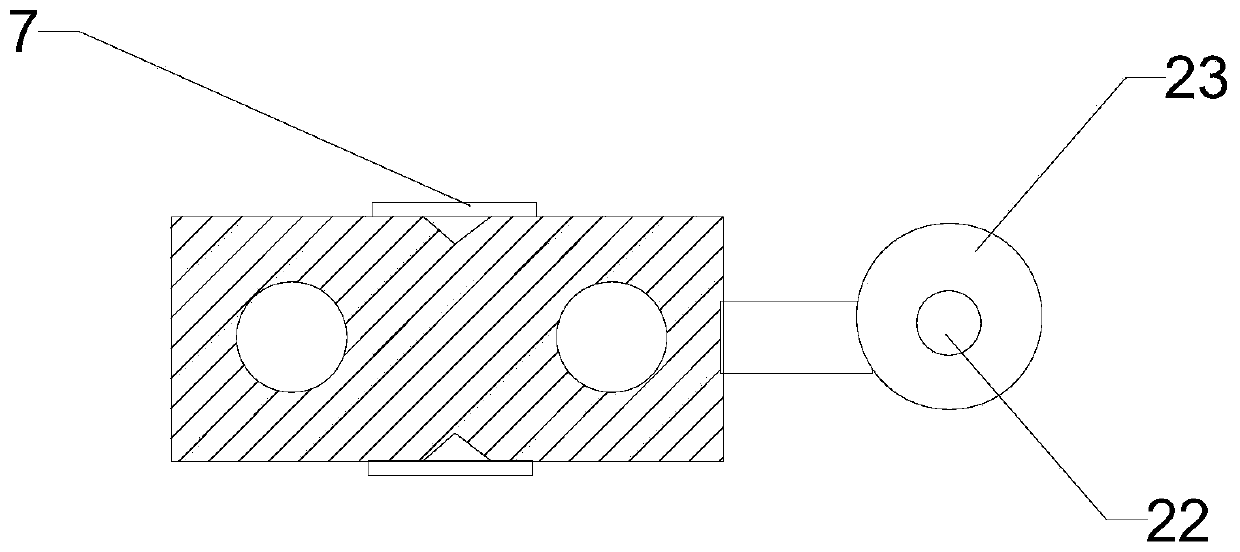

[0027] The invention discloses a butterfly optical cable (see attached figure 1 , 2 , 3, 4), comprising: a pair of single-core cable bodies 1, the single-core cable body 1 is provided with an optical fiber 2 and a sheath layer 3 coated on the outer surface of the optical fiber 2; a pair of single-core cable bodies 1. The main body 4 of the optical cable is connected side by side in the axial direction, and the joints 15 on the upper and lower sides of the optical cable have tearing grooves 5 sunken inward;

[0028] The butterfly optical cable is also provided with a curling section 6 and a coating section 14 along the axial direction, and the tear grooves 5 on the upper and lower sides of the coating section 14 are covered with a waterproof film 7; at least one end of the curling section 6 is provided with There is a first fixed block 8 that protrudes outward, and the first fixed block 8 is connected with a curly elastic piece 12. When the curled elastic piece 12 is opened, t...

Embodiment 2

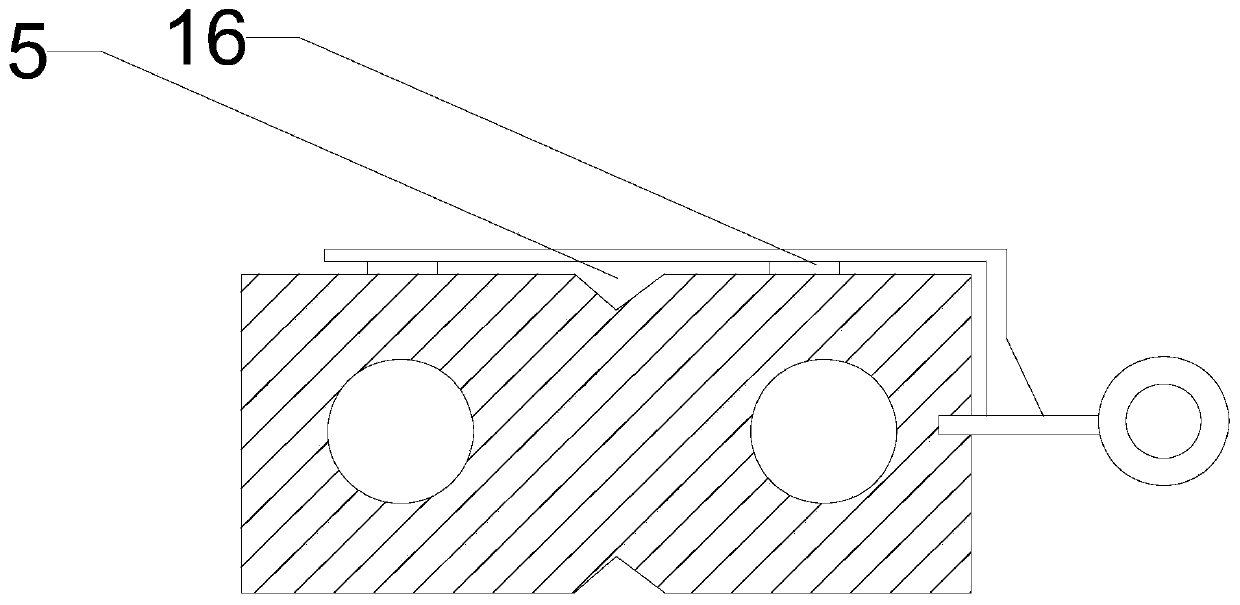

[0032] The invention discloses a butterfly optical cable (see attached Figure 5 , 6 ), including: a pair of single-core cable bodies 1, the single-core cable body 1 is provided with an optical fiber 2 and a sheath layer 3 coated on the outer surface of the optical fiber 2; a pair of single-core cable bodies 1 are axially Connected side by side to form the main body 4 of the optical cable, the joints 15 on the upper and lower sides of the cable have inwardly sunken tearing grooves 5;

[0033] The butterfly optical cable is also provided with a curling section 6 and a coating section 14 along the axial direction, and the tear grooves 5 on the upper and lower sides of the coating section 14 are covered with a waterproof film 7; at least one end of the curling section 6 is provided with There is a first fixed block 8 that protrudes outward, and the first fixed block 8 is connected with a curly elastic piece 12. When the curled elastic piece 12 is opened, the part of the curled e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com