Method for measuring and controlling pulsed extraction column in nuclear chemical engineering field

A technology of pulse extraction column and measurement and control method, which is applied in the direction of program control and electrical program control in sequence/logic controllers, can solve the problems of unknown operating conditions, deviations, inability to give results and prompts, etc., and achieve high measurement and control. Requirements, stable and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings.

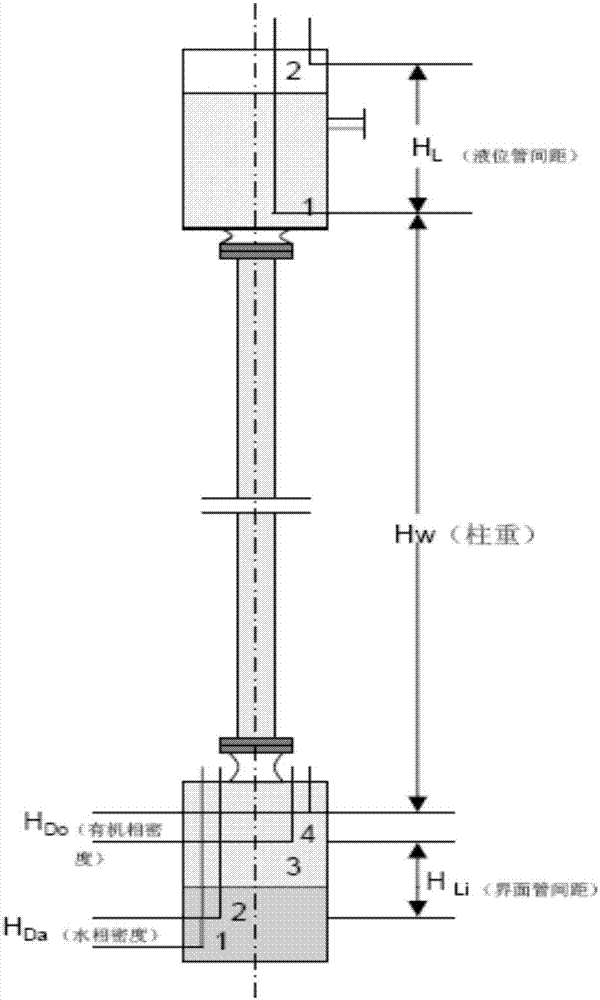

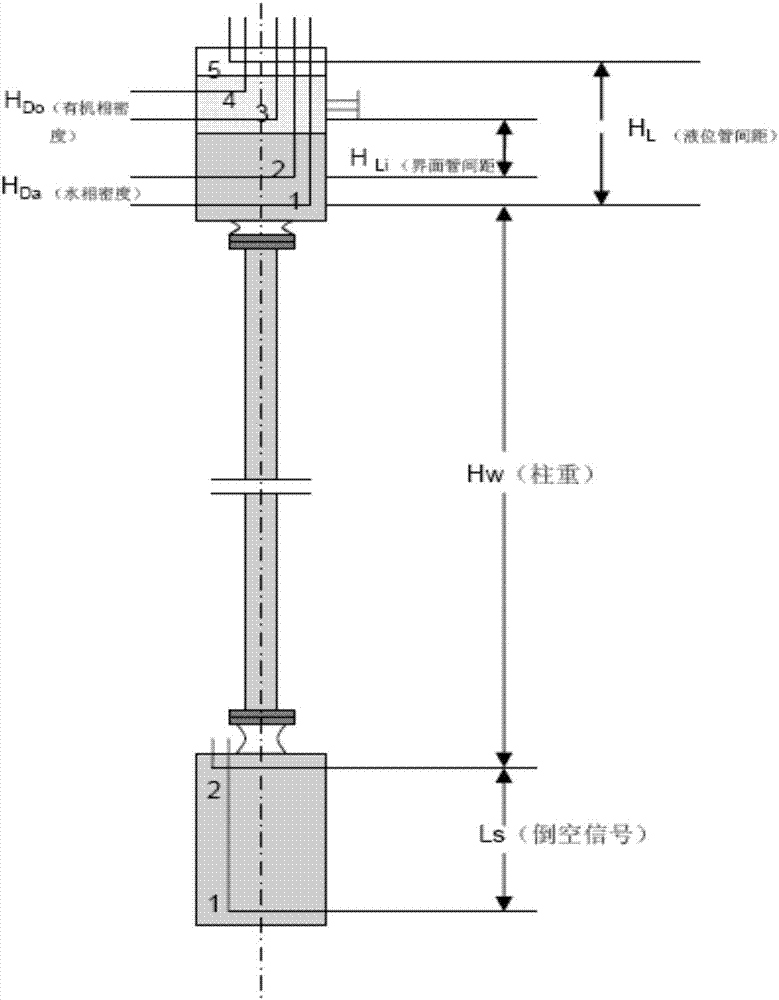

[0040] 1. Measurement and control of organic phase continuous pulse extraction column

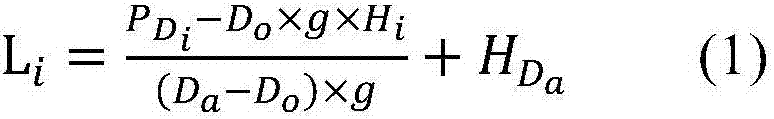

[0041] The principle of measurement and control of an exemplary organic phase continuous pulse extraction column is as follows: figure 1 As shown, when the organic phase continuous pulse extraction column runs stably, the liquid level is stable at the overflow port, and the interface is in the lower expansion section. Measure and control the continuous pulse extraction of the organic phase by measuring and calculating and / or judging interface and emptying signal parameters, in which the interface parameters are calculated figure 1 The pressure difference between the two points 2 and 3 in the expansion section on the medium pulse extraction column is obtained by combining the pressure difference judgment and calculation of other points; the emp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com