A metal shell of communication equipment and its preparation method and application

A technology for communication equipment and metal shells, which is applied in the field of metal shells of communication equipment and its preparation, can solve problems affecting the overall cleanliness and continuity of the appearance, destroying the metal texture of the fuselage, and destroying the overall structure of the metal mobile phone fuselage, etc. Clean and smooth appearance, improved shock resistance and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

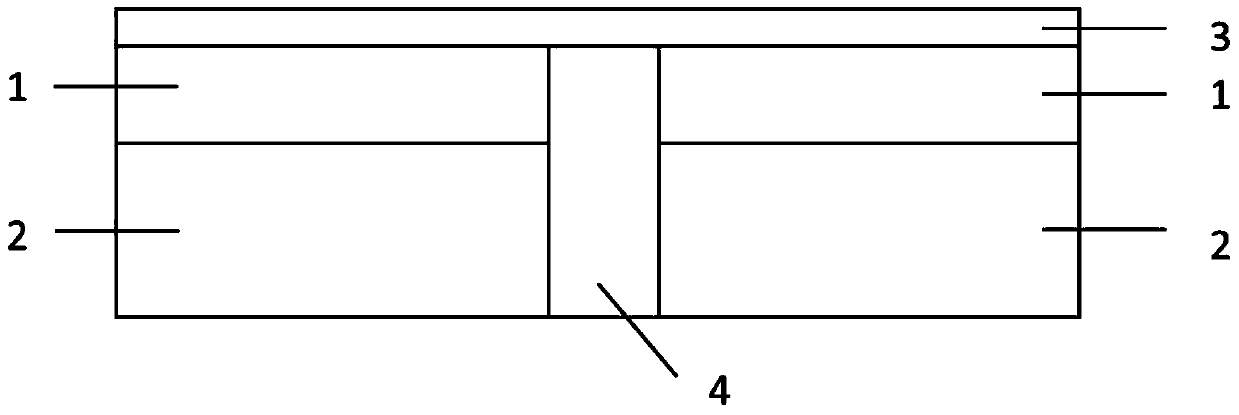

[0023] The invention provides a method for preparing a metal casing of a communication device, wherein the method includes the following steps:

[0024] 1) forming a plastic layer with at least one slit by injection molding on the inner surface of the metal shell;

[0025] 2) forming a decorative layer on the outer surface of the metal shell;

[0026] 3) forming a protective layer on the outer surface of the decorative layer;

[0027] 4) etching the metal shell corresponding to the slit from the inner surface of the metal shell, so that the metal shell at the slit penetrates;

[0028] 5) forming a colloid filler at the slit;

[0029] 6) Remove the protective layer.

[0030] In the present invention, the communication device may be, for example, a mobile phone, a tablet computer, a notebook computer, a bluetooth earphone, a router, or a bracelet.

[0031] In the present invention, the inner surface of the metal casing is defined as the surface of the metal casing facing the...

Embodiment 1

[0066] This embodiment is used to illustrate the preparation method of the metal casing of the communication device provided by the present invention.

[0067] 1) Injection molding

[0068] Plastic layer 2 is formed by nano-injection molding on the inner surface of metal shell 1 (aluminum alloy shell, purchased from Nanping Aluminum Co., Ltd., grade 5052, thickness 0.2mm). The injection molding material is polyphenylene sulfide (PPS) and Glass fiber (weight ratio PPS: glass fiber = 2:1), injection molding conditions are: mold temperature 140°C, nozzle temperature 300°C, dwell time 7s, injection pressure 200MPa, injection time 6s, delay time is 15s, and the cooling time is 10s. Anneal at 120°C for 1.5h after demoulding and cooling. The formed slits are linear, the number of which is 3, the length is 6 cm, the width is 1 mm, and the distance between two adjacent slits is 5 mm.

[0069] 2) Form the decorative layer by anodic oxidation

[0070] Use adhesive tape (GHT2545G gree...

Embodiment 2

[0080] This embodiment is used to illustrate the preparation method of the metal casing of the communication device provided by the present invention.

[0081] The method of Example 1 was used to prepare the metal casing of the communication device, except that in step 2), a hard anodic oxidation method was used to form a decorative layer with a thickness of 45 μm. Hard anodizing conditions: temperature is 10°C, time is 40min, pulse waveform is positive square wave pulse, duty cycle is 80%, frequency is 800Hz, current density is 5A / dm 2 , wherein the oxidizing solution is made up of sulfuric acid, oxalic acid and water, based on 1L of oxidizing solution, the content of sulfuric acid is 180g, the content of oxalic acid is 10g, and the balance is water; in addition, the metal casing of communication equipment is obtained in the same way.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com