Geological examination ore multi-stage crushing equipment

A technology for geological survey and crushing equipment, applied in grain processing and other directions, can solve problems such as inability to prevent debris from splashing, inability to perform multi-stage crushing, etc., to achieve hardness, not easy to deform, improve service life, corrosion resistance and Strong acid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

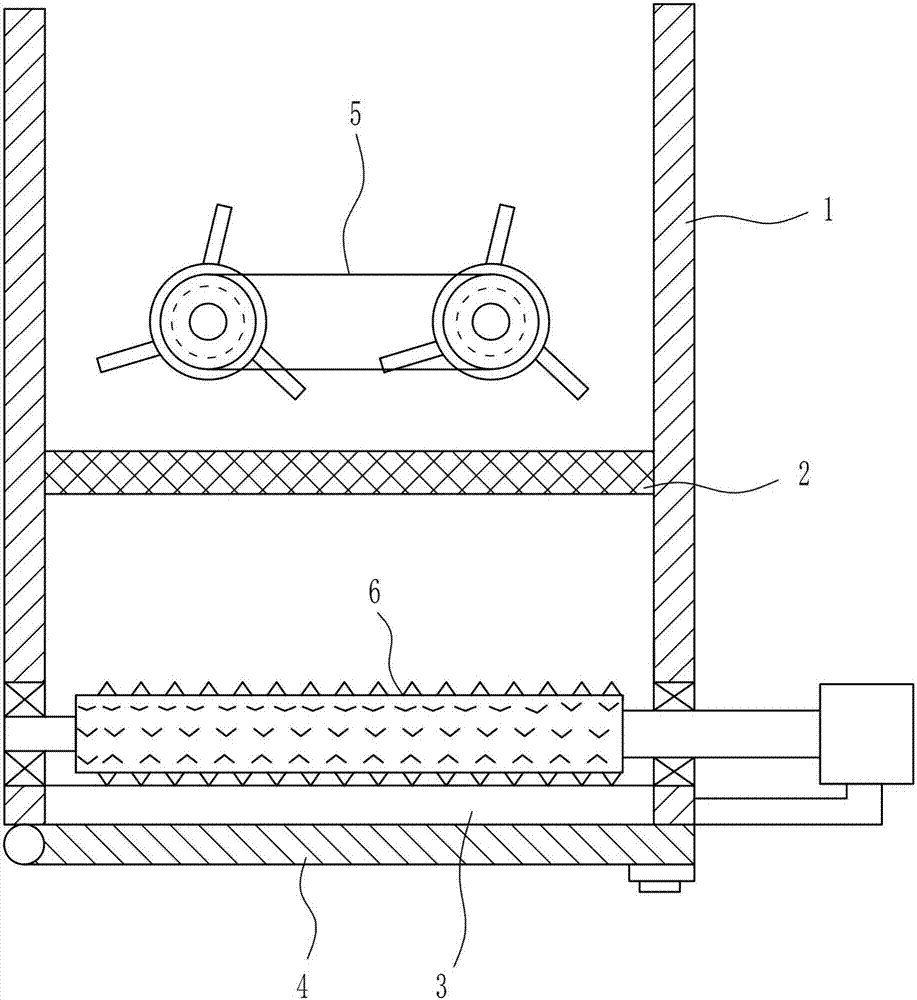

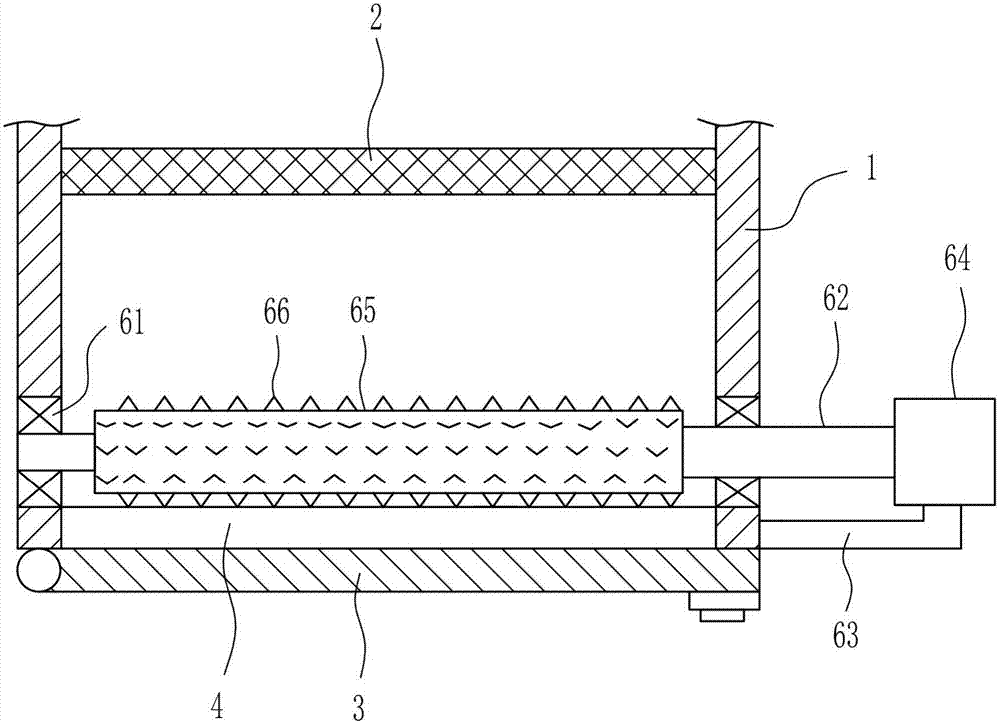

[0034] A multi-stage crushing equipment for geological survey ore, such as Figure 1-5As shown, it includes a crushing box 1, a filter screen 2, a first baffle plate 4, a crushing mechanism 5 and a crushing mechanism 6. The bottom wall of the crushing box 1 has a through hole 3, and the left side of the bottom of the crushing box 1 is connected with a first Baffle plate 4, the right side of the first baffle plate 4 is connected to the right side of the bottom of the crushing box 1 by means of bolts. The upper part of the inner rear wall is provided with a crushing mechanism 5 .

Embodiment 2

[0036] A multi-stage crushing equipment for geological survey ore, such as Figure 1-5 As shown, it includes a crushing box 1, a filter screen 2, a first baffle plate 4, a crushing mechanism 5 and a crushing mechanism 6. The bottom wall of the crushing box 1 has a through hole 3, and the left side of the bottom of the crushing box 1 is connected with a first Baffle plate 4, the right side of the first baffle plate 4 is connected to the right side of the bottom of the crushing box 1 by means of bolts. The upper part of the inner rear wall is provided with a crushing mechanism 5 .

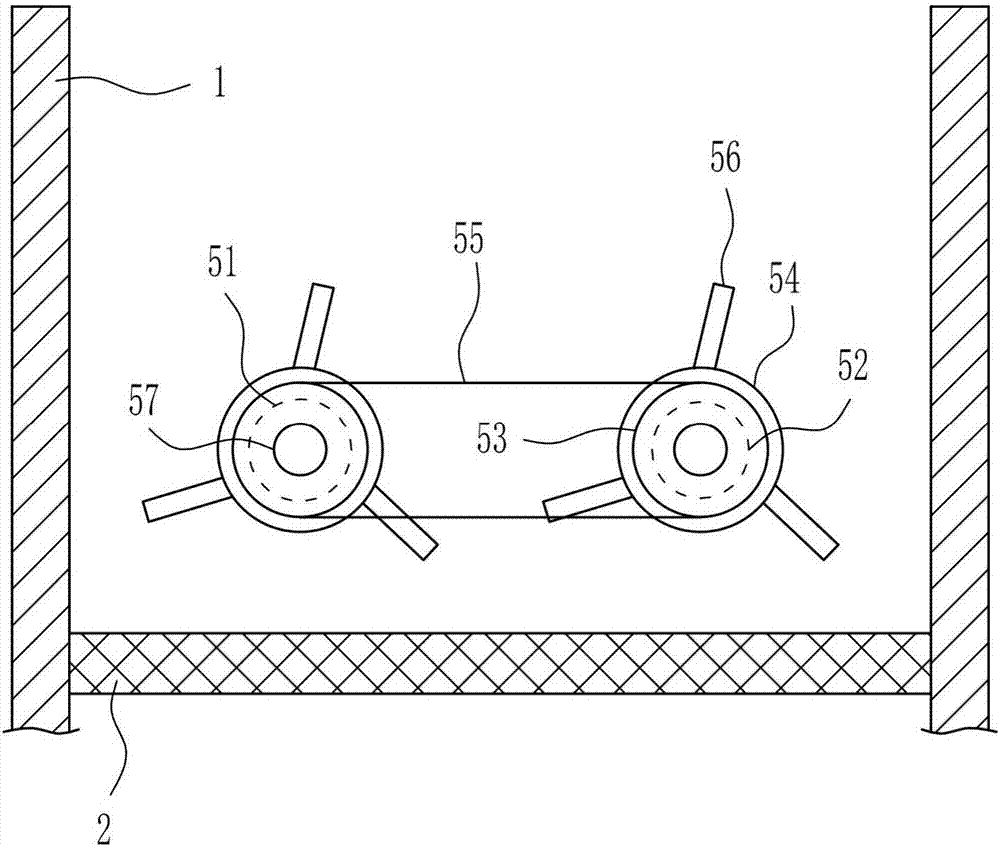

[0037] The crushing mechanism 5 includes a first bearing seat 51, a first motor 52, a first pulley 53, a runner 54, a first flat belt 55, a crushing rod 56 and a first rotating rod 57. The first bearing seat 51 is connected, and the first motor 52 is installed on the upper right side of the inner rear wall of the crushing box 1. The output shaft of the first motor 52 and the first bearing seat 51 ar...

Embodiment 3

[0039] A multi-stage crushing equipment for geological survey ore, such as Figure 1-5 As shown, it includes a crushing box 1, a filter screen 2, a first baffle plate 4, a crushing mechanism 5 and a crushing mechanism 6. The bottom wall of the crushing box 1 has a through hole 3, and the left side of the bottom of the crushing box 1 is connected with a first Baffle plate 4, the right side of the first baffle plate 4 is connected to the right side of the bottom of the crushing box 1 by means of bolts. The upper part of the inner rear wall is provided with a crushing mechanism 5 .

[0040] The crushing mechanism 5 includes a first bearing seat 51, a first motor 52, a first pulley 53, a runner 54, a first flat belt 55, a crushing rod 56 and a first rotating rod 57. The first bearing seat 51 is connected, and the first motor 52 is installed on the upper right side of the inner rear wall of the crushing box 1. The output shaft of the first motor 52 and the first bearing seat 51 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com