Energy-saving and environment-friendly biomass fuel manufacturing equipment

A biomass fuel, energy saving and environmental protection technology, applied in grain processing, solid separation, sieving and other directions, can solve the problems of insufficient crushing of raw materials, unqualified subsequent fuel, etc., to avoid sticking of raw materials, ensure high quality, and improve cutting The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

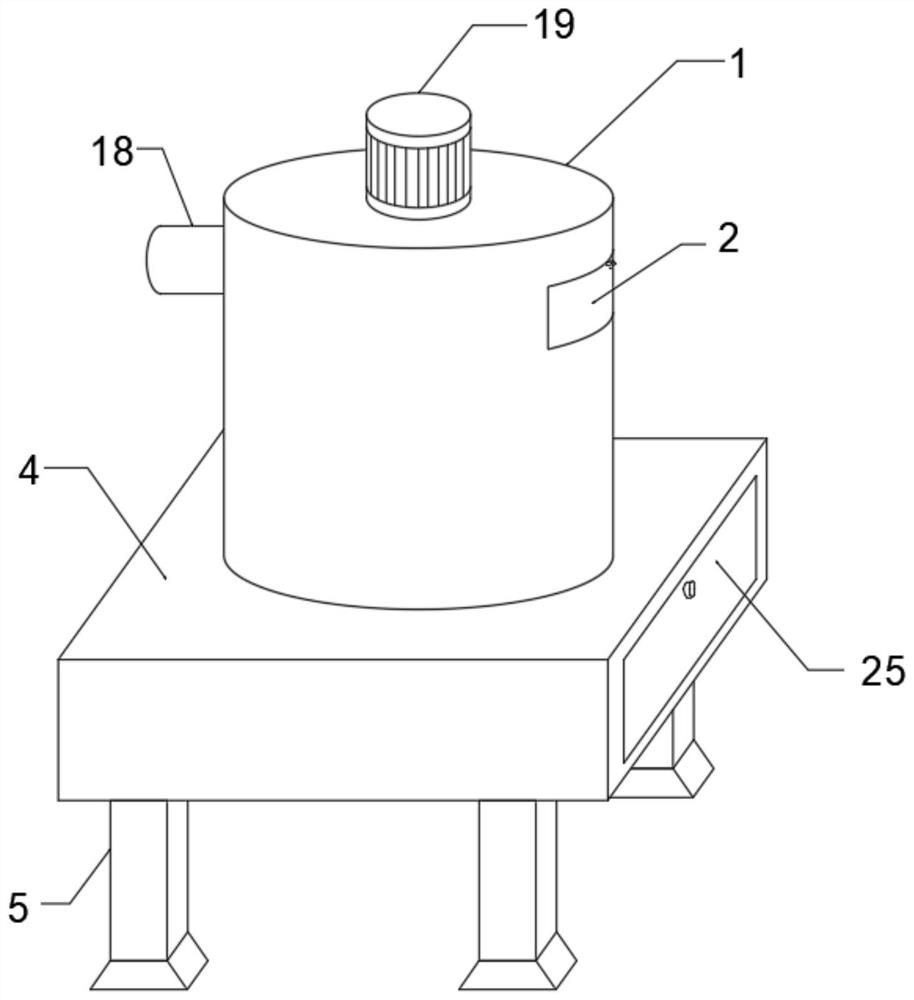

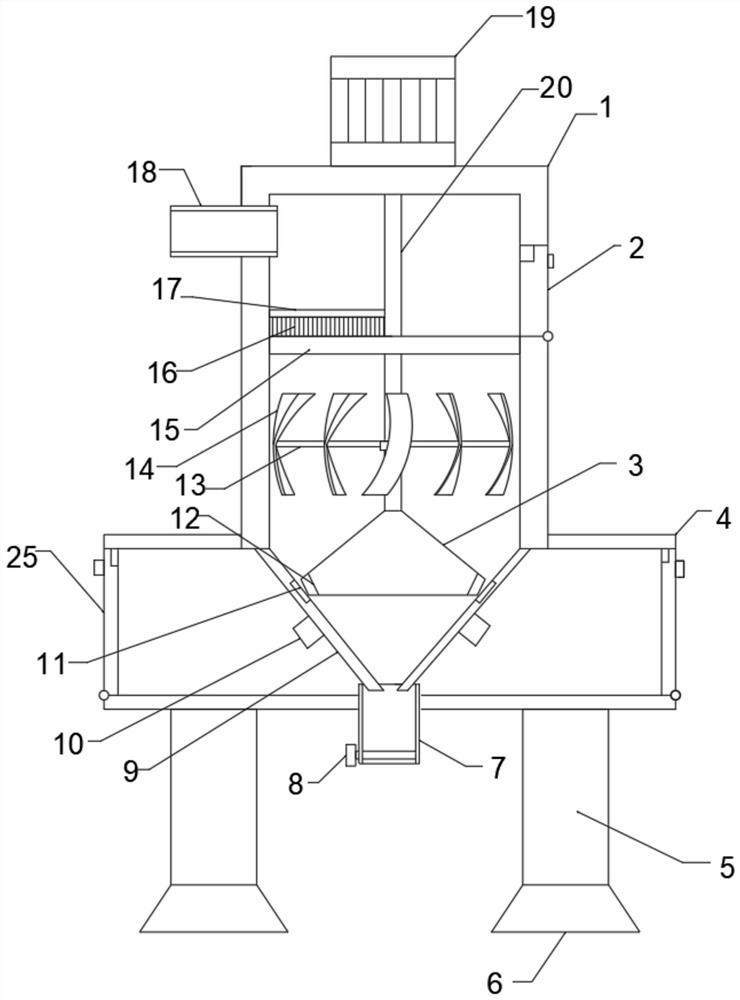

[0021] refer to Figure 1-2 , an energy-saving and environment-friendly biomass fuel manufacturing equipment, comprising a box body 1, a feed pipe 18 is fixedly connected to the outer wall of one end of the box body 1, a motor 19 is fixedly connected to the outer wall of the top of the box body 1, and a rotating shaft is connected to the inner wall of the box body 1 for rotation 20, the rotating shaft 20 is fixedly connected with the motor 19, the outer wall of the rotating shaft 20 is fixedly connected with a plurality of first connecting rods 13, the outer wall of the first connecting rod 13 is fixedly connected with a plurality of cutting blades 14, and the cutting blades 14 are arranged in an arc shape, cutting The bottom of the blade 14 is provided with a turntable 3, the top of the turntable 3 is fixedly connected to the bottom of the rotating shaft 20, the outer wall of the turntable 3 is fixedly connected with a second grinding block 11, and both ends of the bottom oute...

Embodiment 2

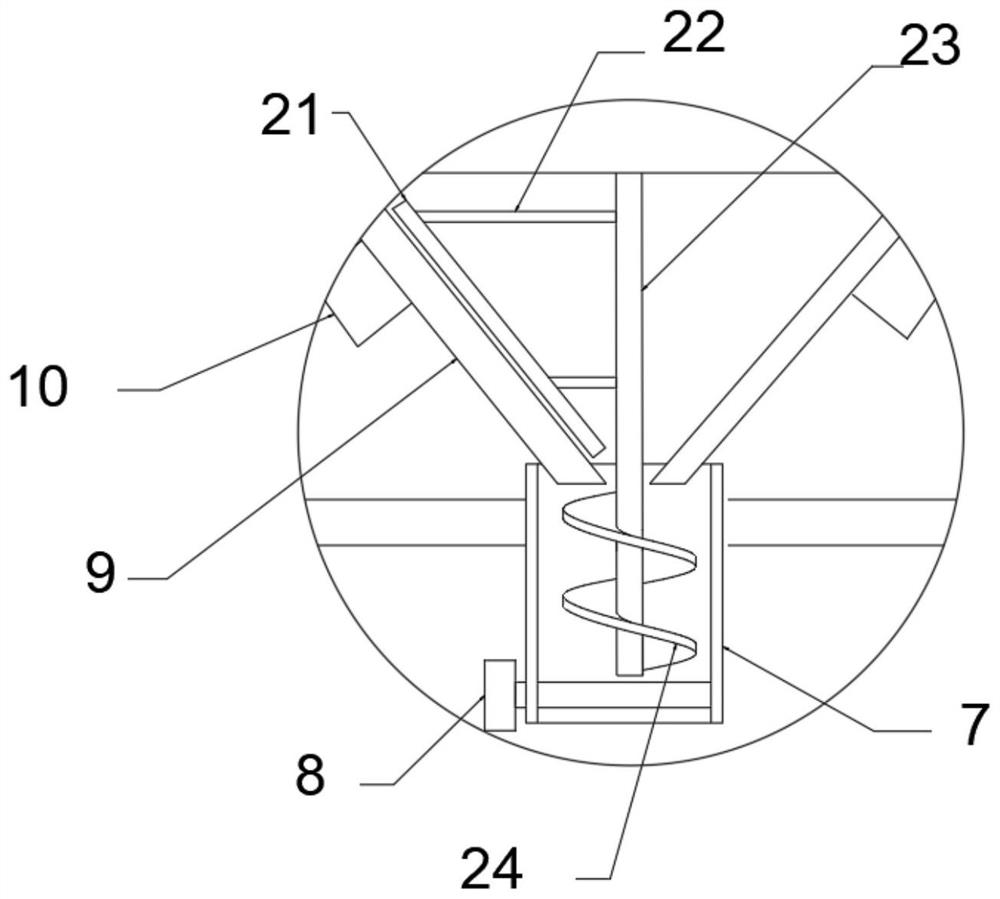

[0027] refer to figure 1 and image 3 , an energy-saving and environment-friendly biomass fuel manufacturing equipment, the outer wall of the bottom of the rotating table 3 is fixedly connected with a second rotating rod 23, the outer wall of the second rotating rod 23 is fixedly connected with a second connecting rod 22, and the other end of the second connecting rod 22 is fixedly connected There is a scraper 21, and the scraper 21 is arranged to be inclined, and the inner wall of the discharge pipe 7 is provided with an auger 24, and the auger 24 is fixedly connected with the second rotating rod 23.

[0028] During use, the rotating table 3 is set to drive the second rotating rod 22 to rotate, thereby driving the scraper 21 at one end of the second rotating rod 22 to scrape the surface of the second filter plate 9 to avoid the adhesion of the raw materials. The auger 24 can further crush the raw materials in the discharge pipeline 7, and avoid discharge blockage, improving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com