Composite bone crusher for spine surgery

A bone crusher and surgical technology, applied in the fields of application, medical science, food science, etc., can solve the problems of residual bone fragments, inconvenient use, etc., and achieve the effect of reducing residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

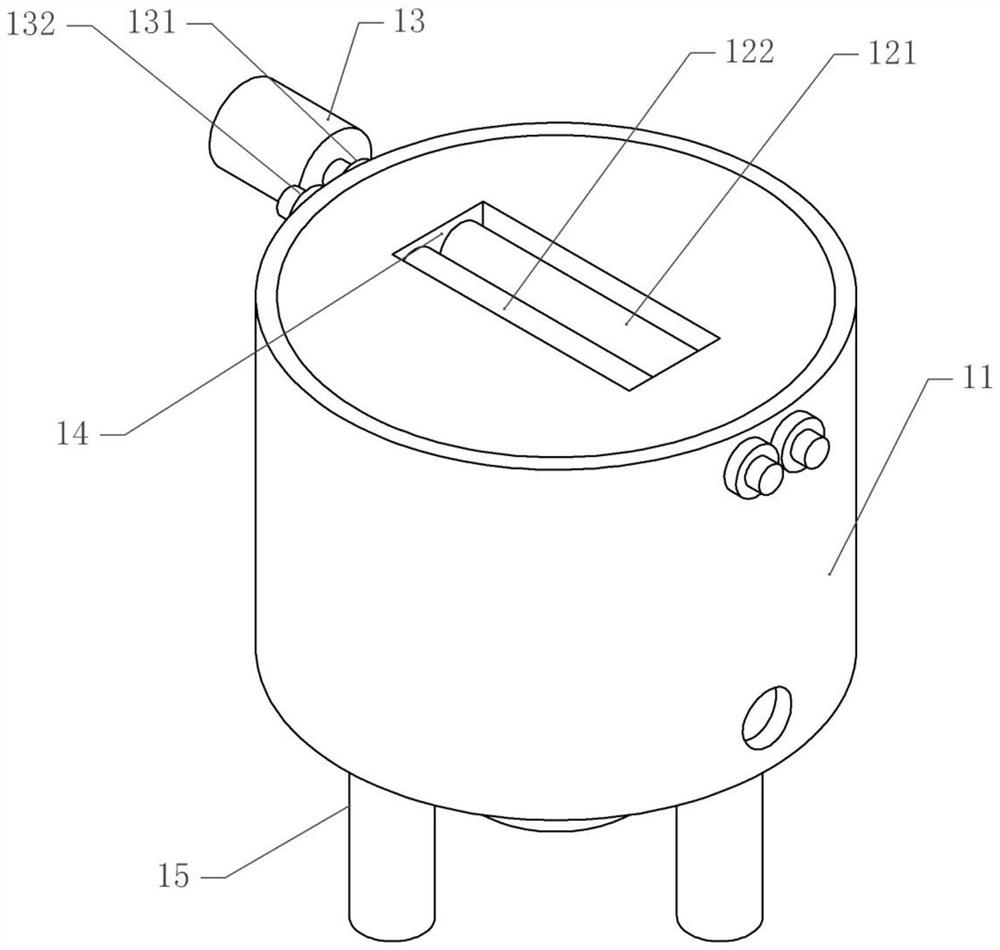

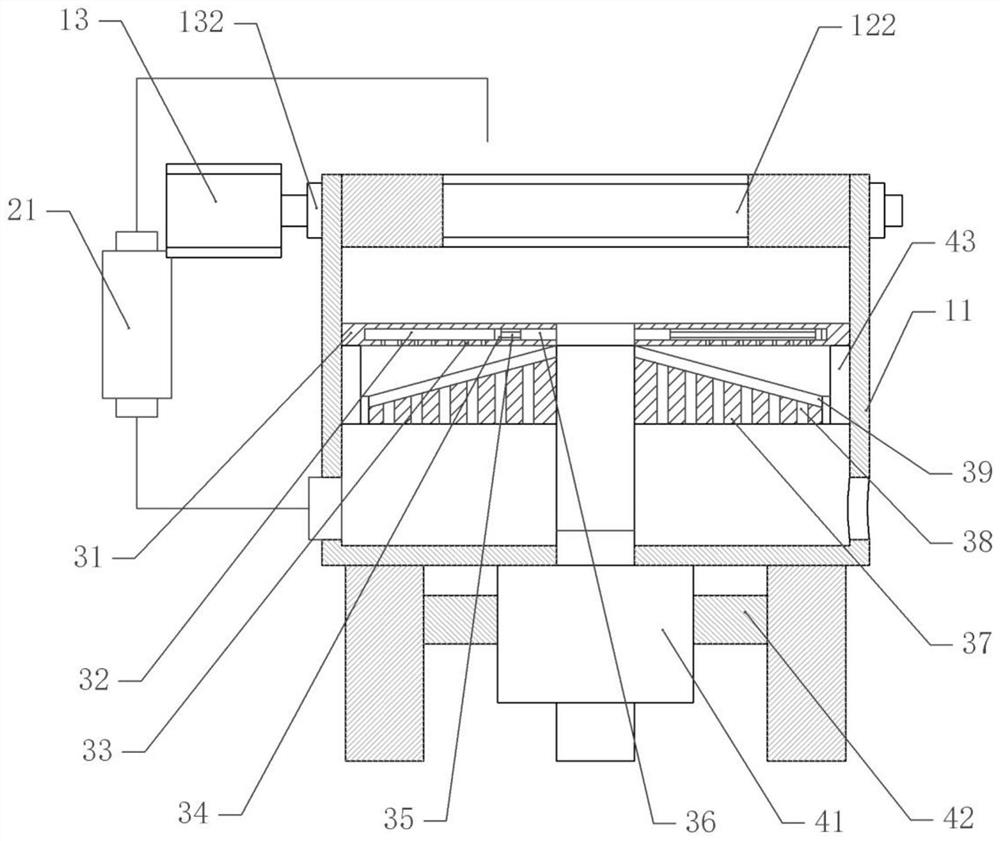

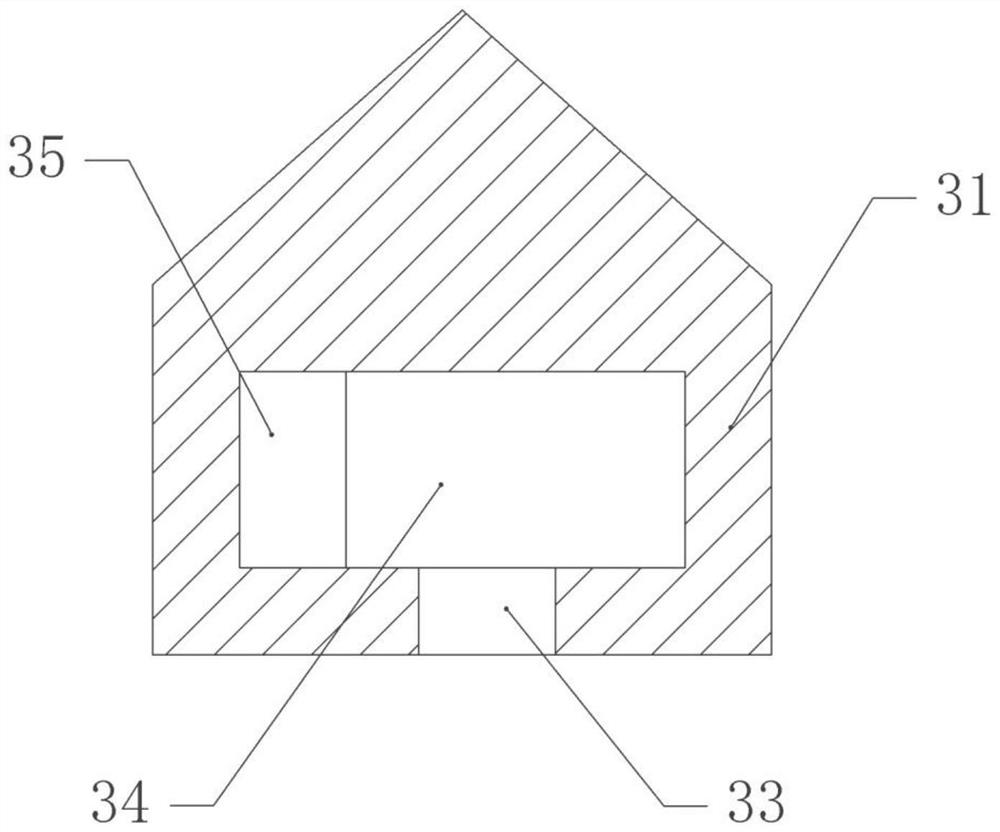

[0038] A kind of composite bone crusher for spinal surgery, as attached figure 1 , attached figure 2 And attached image 3 As shown, the main body 11 is included, and the top wall of the main body 11 is provided with a feeding port 14, and a crushing pair of rollers is arranged in the feeding port 14. In this embodiment, the crushing pair of rollers includes a first roller 121 and a second roller 122, The first roller 121 and the second roller 122 are rotatably connected with the body 11, and a drive assembly is installed on the body 11. The drive assembly includes a single-phase motor 13 fixed on the body 11, and a main gear 131 coaxially fixedly connected with the first roller 121. The main gear 131 meshes with the slave gear 132 coaxially and fixedly connected with the second roller 122 .

[0039] Bolts on the bottom wall of the body 11 are fixed with a number of support shafts. A support plate 42 fixed on the support shaft is provided below the body 11. A power part is ...

Embodiment 2

[0048] The difference between the second embodiment and the first embodiment is that the attached Figure 4 As shown, a third grinding plate 44 is threaded on the rotating shaft, and the third grinding plate 44 is vertically slidably connected with the second grinding plate 43. The third grinding plate 44 is provided with several grinding holes 45, and the grinding holes 45 and the screening holes 38 Staggered settings.

[0049] The specific implementation process is as follows:

[0050] The bone fragments that are pulverized by the first grinding plate 37 and the second grinding plate 43 fall on the third grinding plate 44, and of course the bone fragments falling from the screening hole 38 on the third grinding plate 44 will also fall to the third grinding plate 44. Three grinding plates 44 on.

[0051] Since the motor 41 drives the rotating shaft to reciprocate, the third grinding plate 44 vertically reciprocates under the limit action of the second grinding plate 43, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com