A kind of composite resin emulsion for toner and preparation method thereof

A composite resin and emulsion technology, used in instruments, optics, developers, etc., can solve the problems of carrier and developing roller contamination, free wax particles, poor compatibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

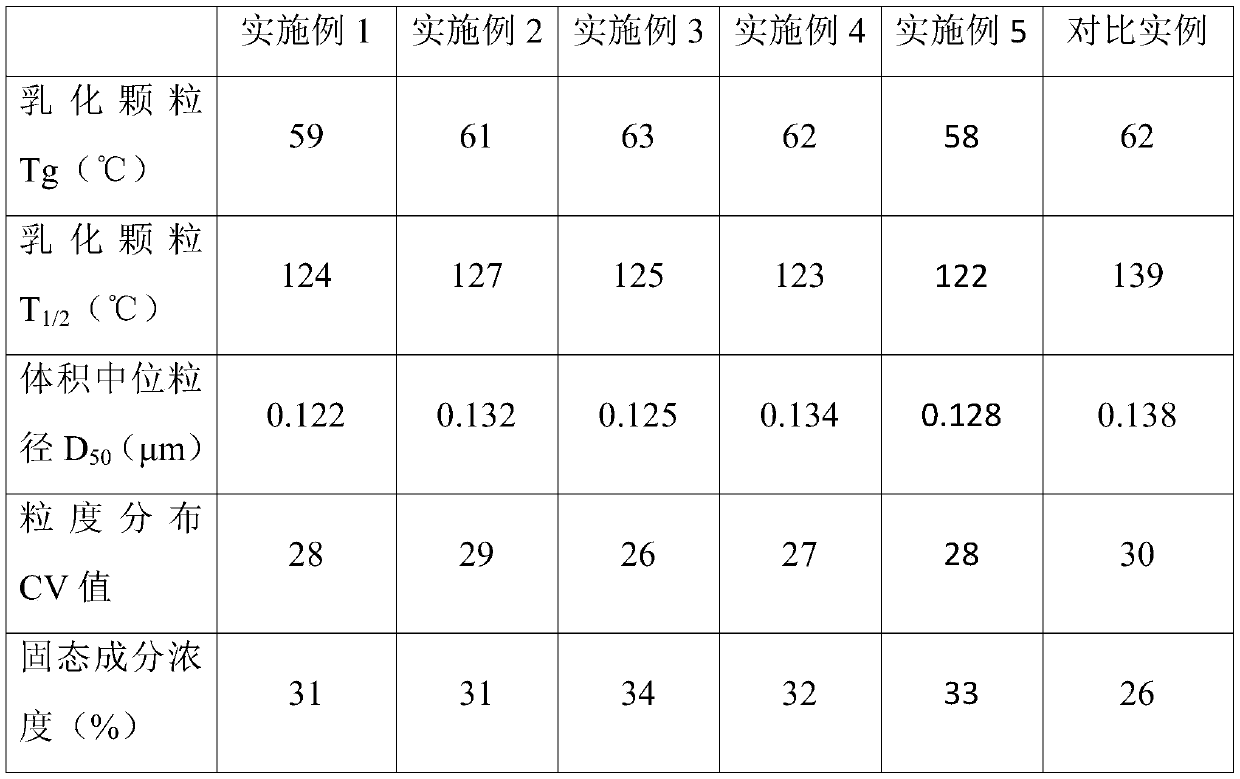

Examples

preparation example Construction

[0064] Preparation of Wax-Modified Crystalline Polyester A:

[0065] 52.5g montan acid wax U (acid value of 72 to 92 mgKOH / g), 150 g of terephthalic acid, 170 g of 1,4-butanediol and 25 g of catalyst dibutyltin oxide were put into a reactor equipped with a stirrer, thermometer, condenser and nitrogen introduction pipe , the temperature was raised to 180°C under nitrogen atmosphere, and reacted for 2h; then 15g 1,6-adipic acid was put into the reaction kettle, and the temperature was further raised to 210°C, and the reaction was performed for 3h; vacuumed to 2kPa, continued to react for 0.5h, material, cooled to room temperature, pulverized, finely powdered, and sieved to prepare wax-modified crystalline polyester A. The obtained wax-modified crystalline polyester A had a melting point (Tm) of 58° C., Mn of 4380, Mw of 16,720, Mw / Mn of 3.82, and an acid value of 27 mgKOH / g.

[0066] Preparation of styrene-acrylic resin B

[0067] Put 300 g of xylene into the reaction kettle...

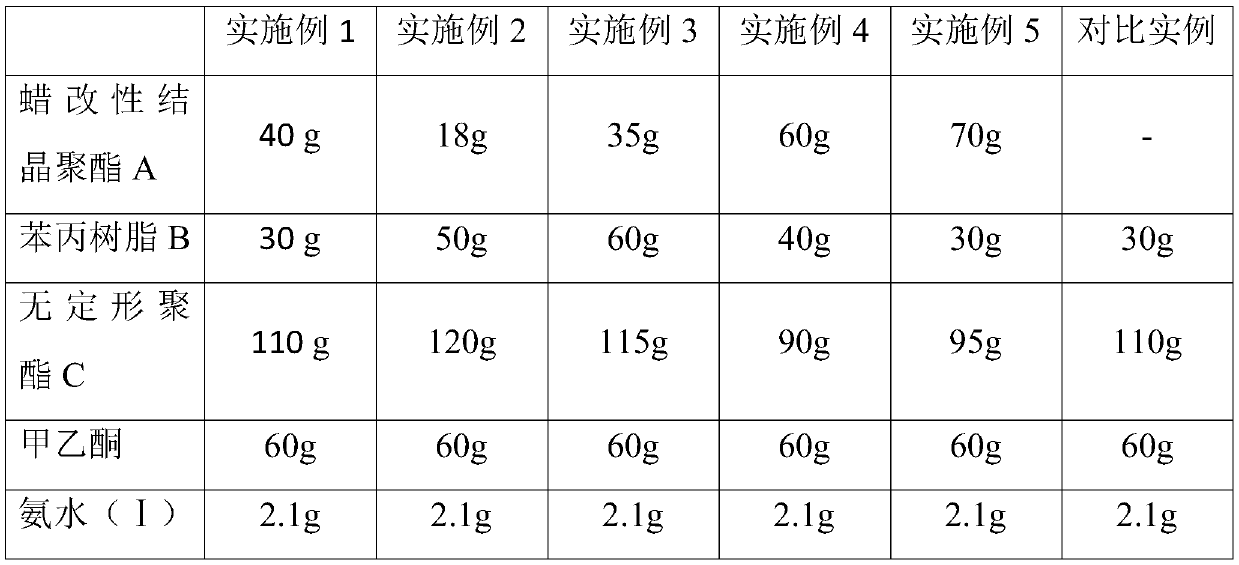

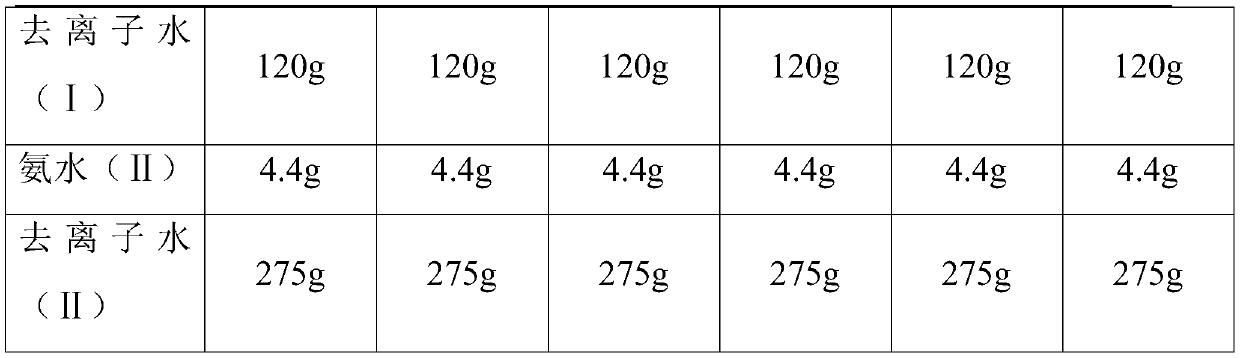

Embodiment 1

[0071] 30g of styrene-acrylic resin B was added to 60g of methyl ethyl ketone, heated at 65°C and stirred at a speed of 500rpm for 20min, then added 120g of deionized water, added 2.1g of ammonia water (mass fraction was 10%), and continued to stir at a speed of 500rpm to form Uniform phase. Then, 40 g of the above wax-modified crystalline polyester A and 110 g of amorphous polyester C were respectively added, heated at 75°C and stirred at a speed of 1,000 rpm for 20 min, and then 4.4 g of ammonia water (mass fraction of 10%) was added to neutralize the dissolved Resin, continue to stir for 10min to form a mixed solution of styrene-acrylic resin and polyester resin. Then, under the condition of heating at 78°C and vigorous stirring at a speed of 3,000rpm, 275g of deionized water was slowly added at a rate of 6.8g / min to make the resin solution phase inversion, and the organic solvent was removed by distillation to form a styrene-acrylic resin. / Polyester resin composite emul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com