Micro high-flow motor

A high-flow, motor technology, applied in liquid displacement machinery, variable displacement pump components, piston pumps, etc., can solve the problems of low flow rate of micro motors, weak suction and release force, human discomfort, etc., to achieve soft airflow in and out, Guarantees tightness and relieves discomfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with drawings and embodiments.

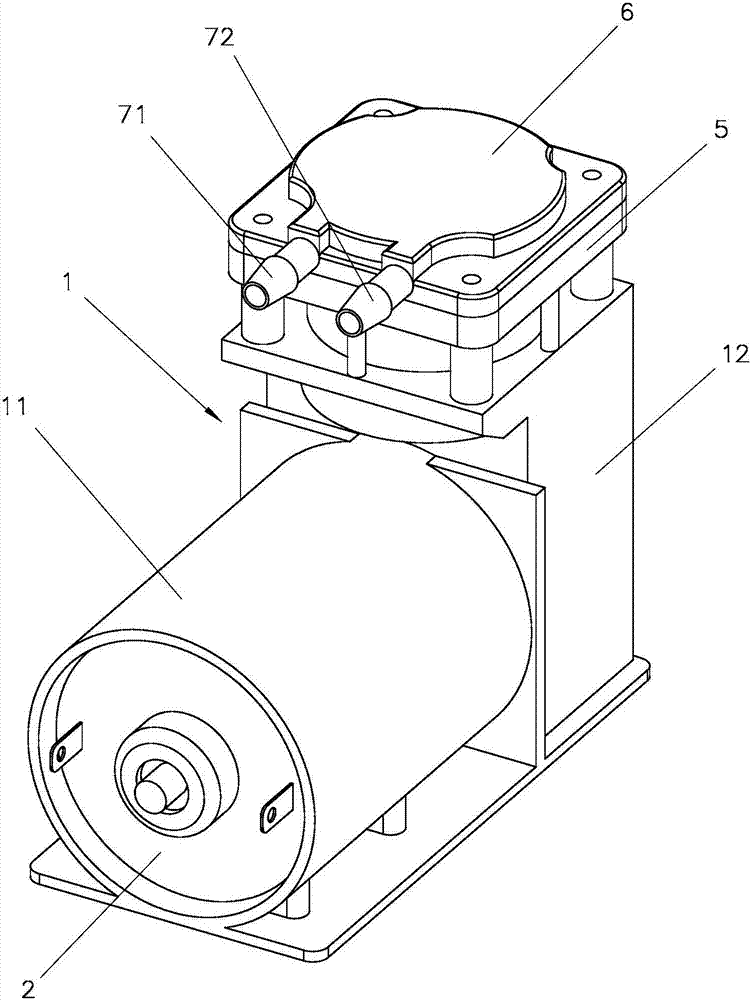

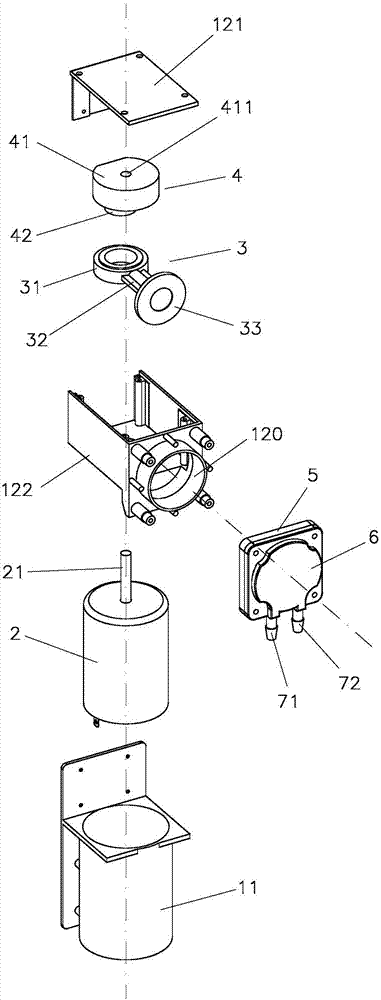

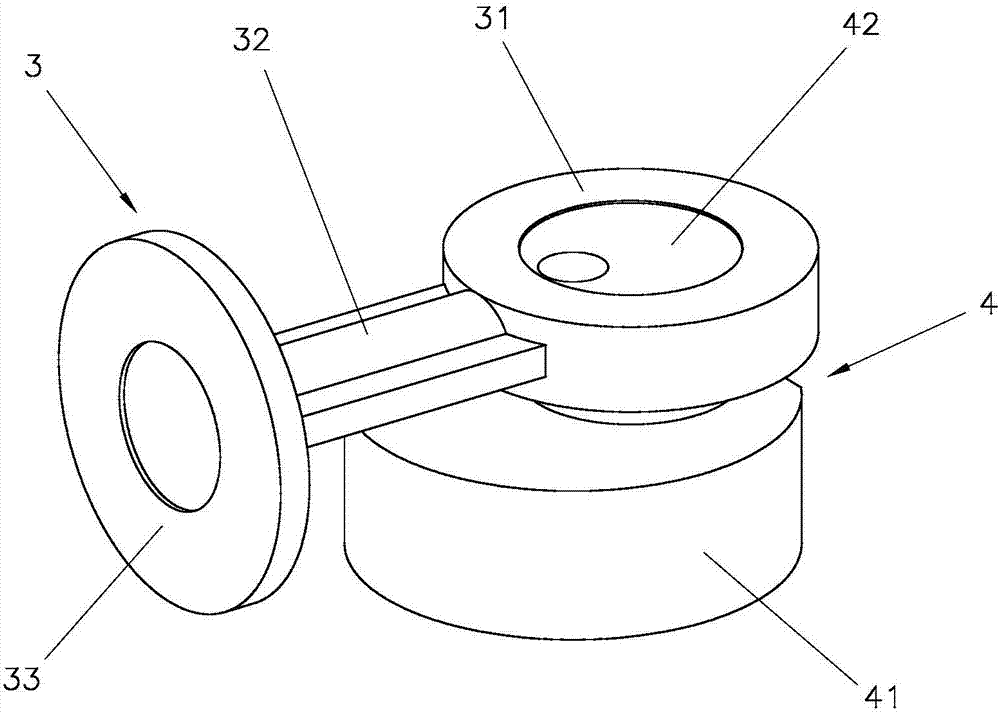

[0024] Such as Figure 1 to Figure 4 As shown, the miniature high-flow motor of the present invention includes a frame 1, a motor 2, a pump body and a cover body with an air inlet pipe 71 and an air outlet pipe 72. The frame 1 of this embodiment includes a motor housing 11 and an installation Shell 12, the motor shell 11 is cylindrical, and a connecting plate is connected to the outside thereof, and the motor 2 is installed in the motor shell 11; the mounting shell 12 includes an upper shell 121 and a lower shell 122, the lower shell The shaft hole 21 of the power supply motor 2 is provided on the body 122, and the pump body is installed in the lower casing 122, the rear cover is closed on the casing 120, and the casing is tightened by screws to form a casing with good airtightness; The connecting plate of the motor casing 11 is provided with a connection hole, and aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com