Pneumatic flow-guiding cleaning tank for pickling of fasteners

A technology for cleaning tanks and fasteners, which is applied in the field of fastener production supporting devices, can solve the problems of small quantity and poor cleaning effect, etc., and achieves the effect of fast cleaning speed and good cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

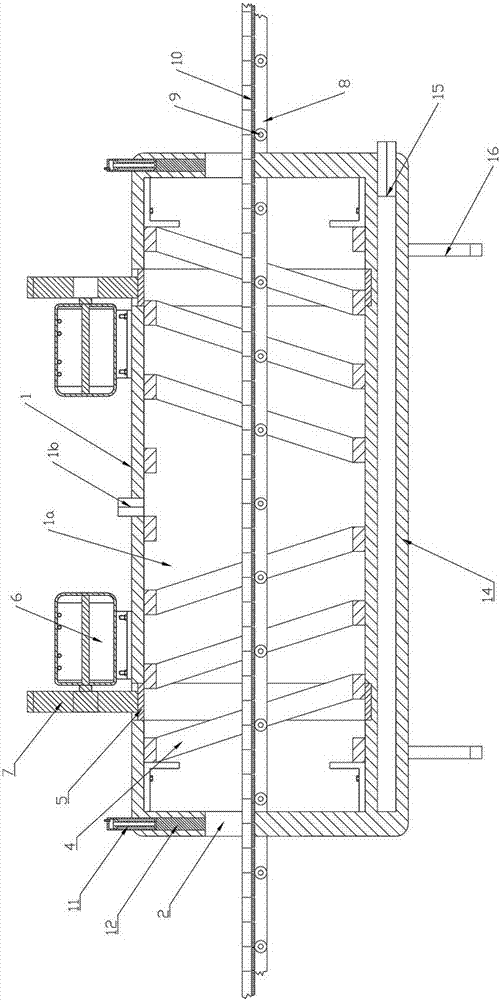

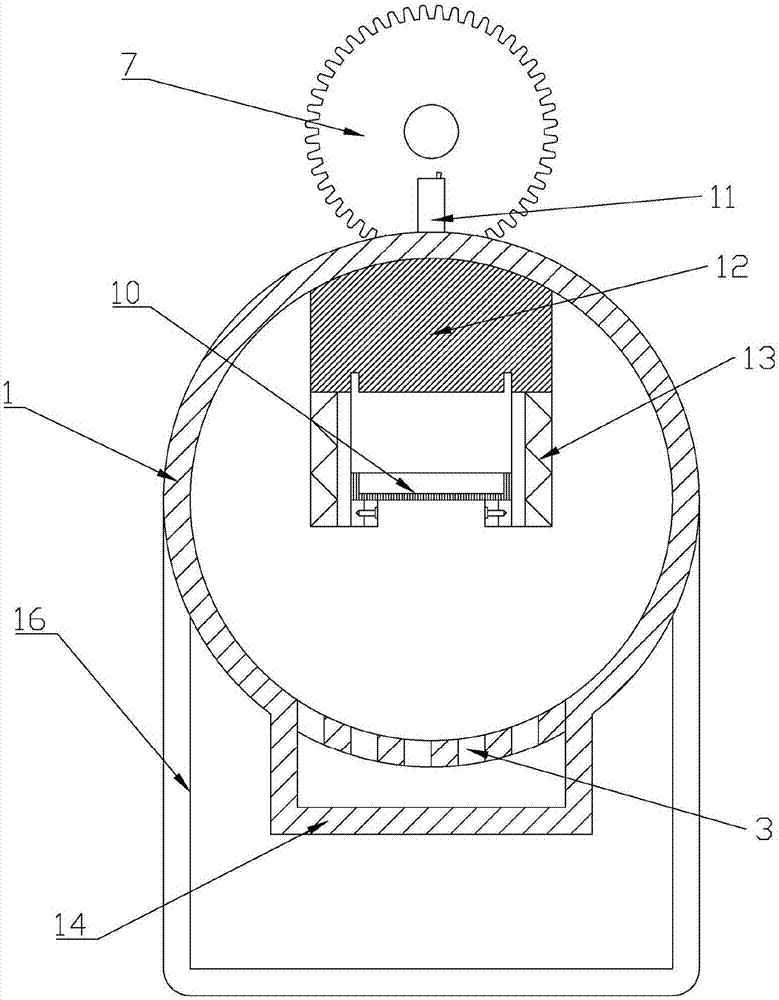

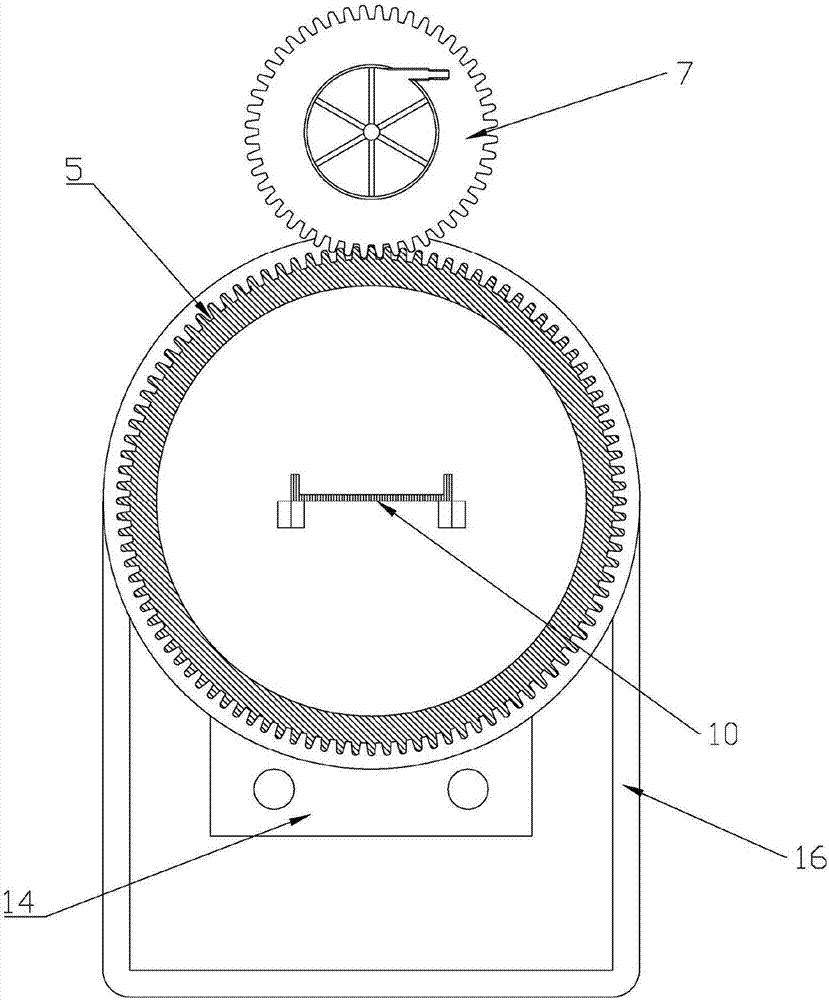

[0016] see figure 1 As shown, the present invention provides a pickling cleaning tank for pneumatic diversion fasteners, including a cleaning tank 1 with a liquid storage chamber 1a inside and a transmission mechanism for transporting fasteners to be cleaned. The two parts of the cleaning tank 1 The end is provided with an opening 2 for the transmission mechanism to pass through, the upper part of the cleaning tank 1 is provided with a water inlet 1b communicating with the liquid storage chamber 1a, and the lower part of the cleaning tank 1 is provided with a water leakage hole 3 communicating with the liquid storage chamber 1a; The cleaning tank 1 is provided with two oppositely arranged spiral rollers 4, the spiral direction of the two spiral rollers 4 is opposite, the peripheral side of the spiral roller 4 is provided with a roller gear 5, a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap