A reinforced structure form of built-in gangway for ultra-large container ship

A technology for strengthening the structure of container ships, applied to ship accessories, transportation and packaging, cargo handling equipment, etc., can solve problems such as easy resonance, shaking of the gangway, large space, etc., to ensure mechanical operation, optimize the size of the strong frame, and meet The effect of access requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

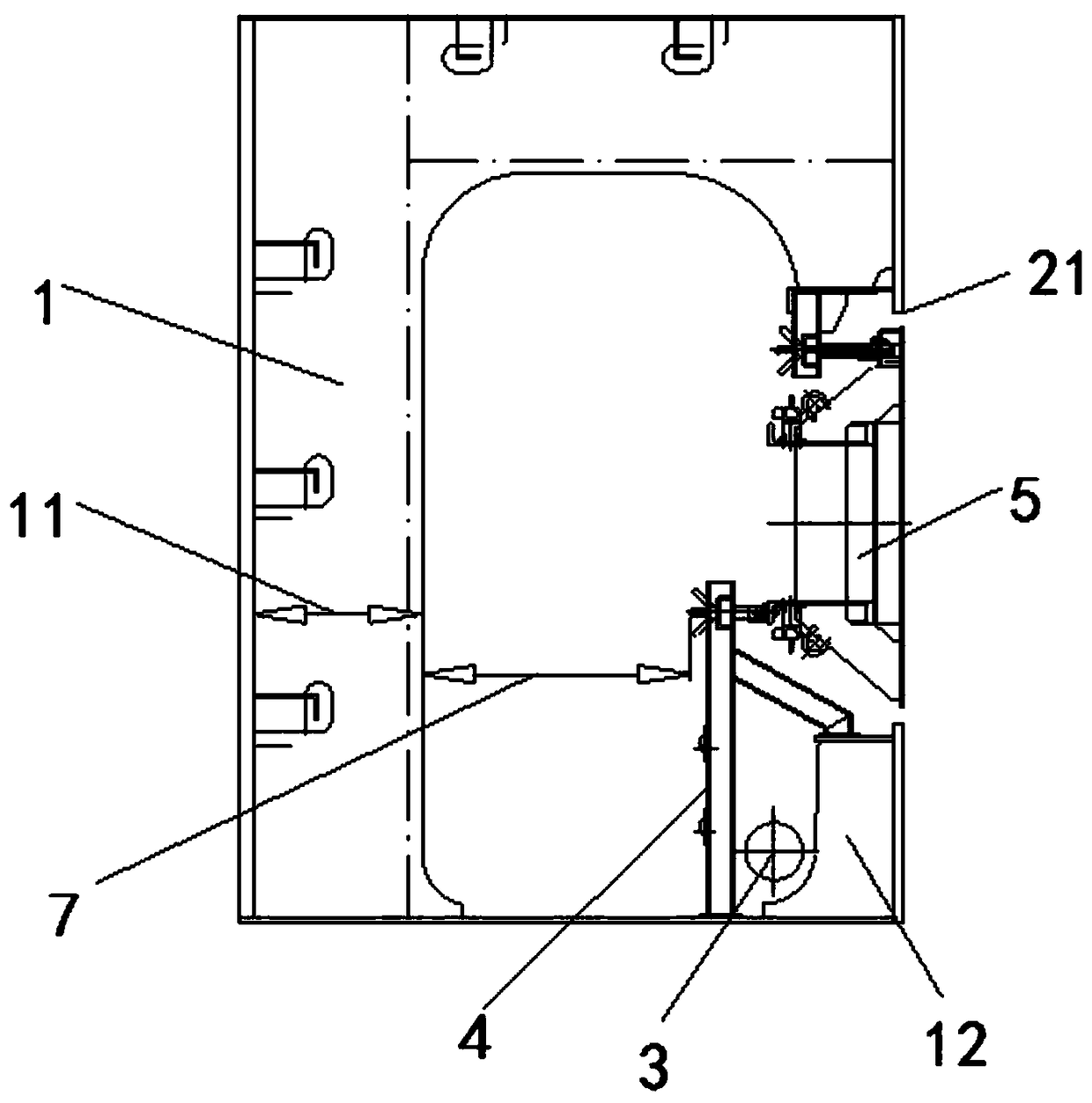

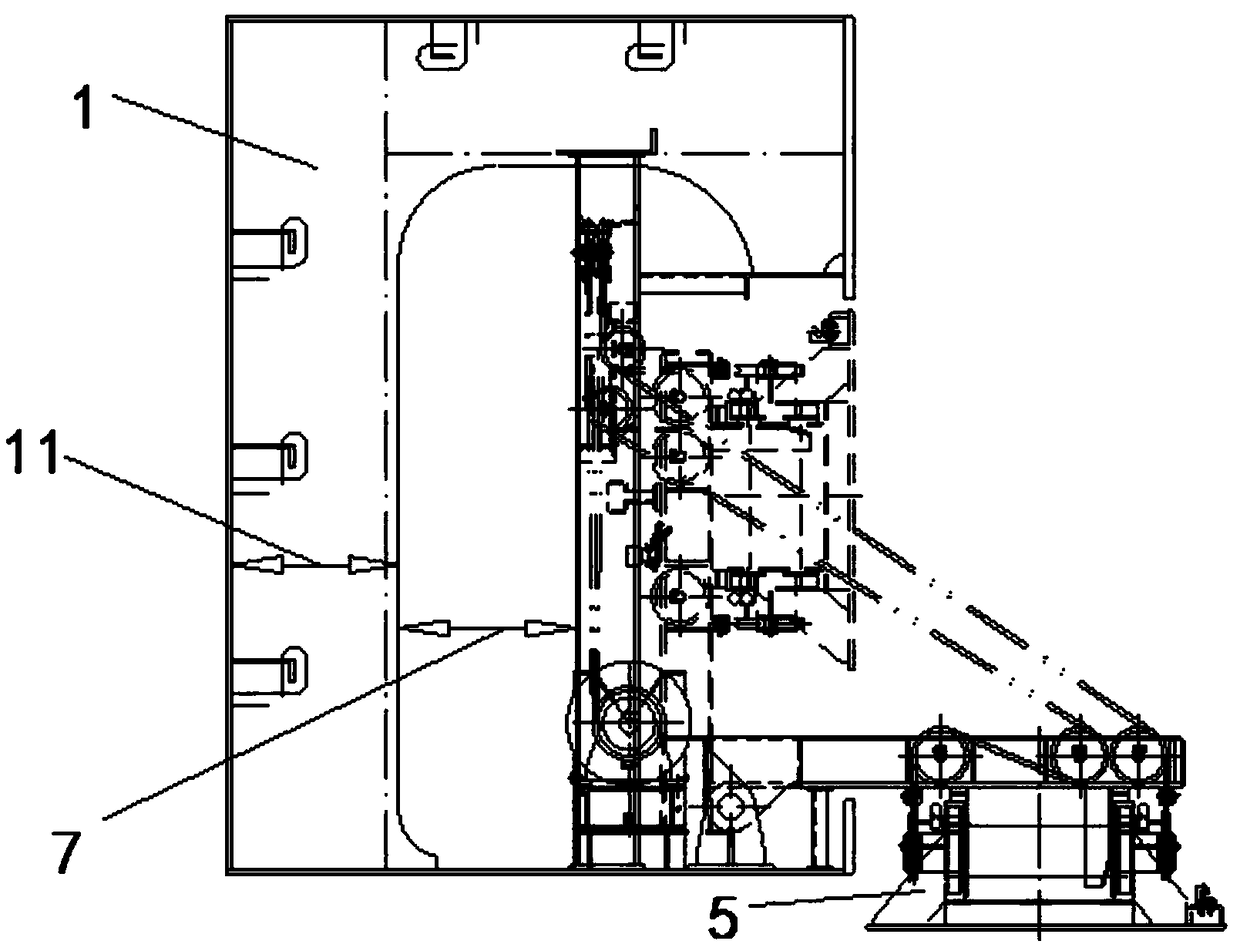

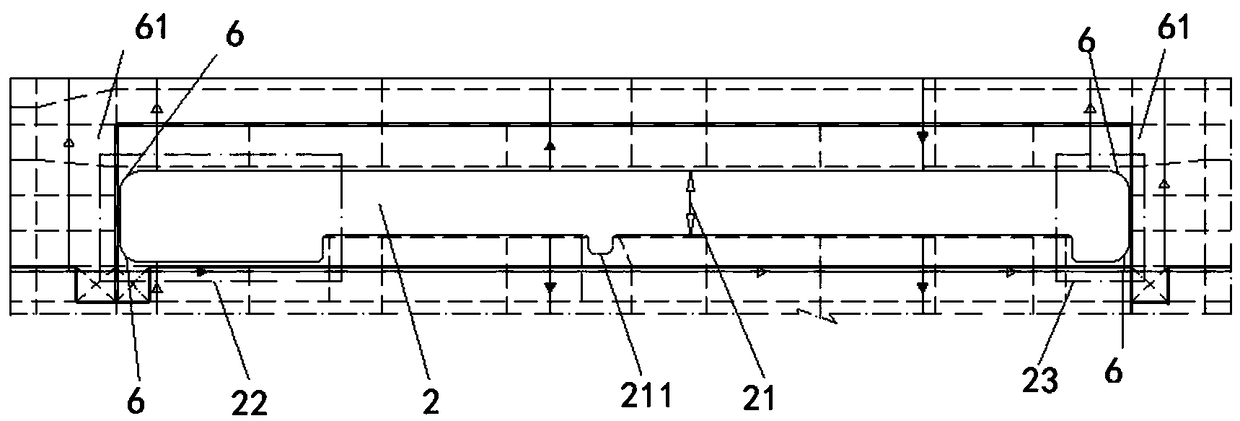

[0025] figure 1 It is a layout diagram of a super-large container ship with a reinforced structure built in a gangway ladder when it is accommodated. figure 2 It is a schematic diagram of a reinforced structural form of an ultra-large container ship embedded with a gangway when the gangway is lowered. image 3 It is a schematic diagram of the opening of the outer plate of the reinforced structure of a super-large container ship with built-in gangway according to the present invention.

[0026] See Figure 1 to Figure 3 As shown, in a preferred embodiment, it shows a reinforced structure form of a built-in gangway of an ultra-large container ship, which is characterized in that it includes:

[0027] Two local strong frames 1, two local strong frames 1 are arranged in the cargo hold of an ultr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com