Method of TA18 pipe fatigue strength for increasing aviation hydraulic pipeline

A hydraulic pipeline and fatigue strength technology, applied in the field of titanium alloy tube manufacturing, can solve the problems that cannot meet the fatigue strength requirements of aviation hydraulic pipelines and affect the reliability of aviation hydraulic pipelines, so as to improve fatigue strength and eliminate residual Stress, the effect of improving the fatigue strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art.

[0020] This embodiment provides a method for improving the fatigue strength of the TA18 pipe used in aviation hydraulic pipelines, comprising the following steps: projecting solid particles onto the surface of the TA18 pipe with a pressure greater than 0.1MPa, and the surface of the TA18 pipe For striking, the mesh number of the solid particles is not less than 80.

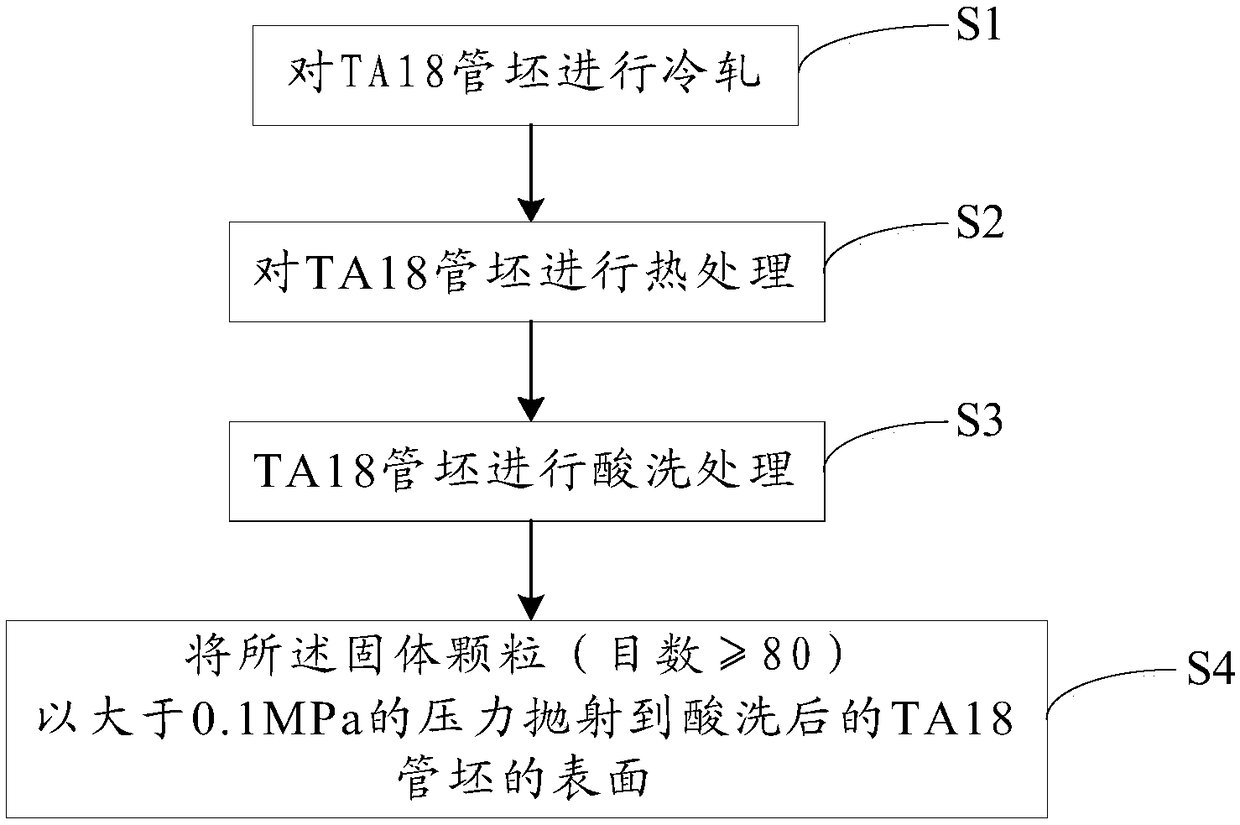

[0021] refer to figure 1 As shown, the method specifically includes the following steps:

[0022] S1. Cold rolling the TA18 tube billet to make the TA18 tube preliminary shape. At this time, the cold-processed tube billet has a lot of internal stress;

[0023] S2. Carry out heat treatment to the cold-rolled TA18 billet, specifically high-strength annealing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com