Connecting structure for end parts of longitudinal aggregates of bulk carrier

A technology for connecting structures and bulk carriers, which is applied to hull parts, bulk cargo, hulls, etc. It can solve problems such as increasing the connecting structure, increasing construction costs, and difficulty in satisfying fatigue strength, so as to control the weight of steel materials and alleviate Effect of stress concentration and reduction of construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

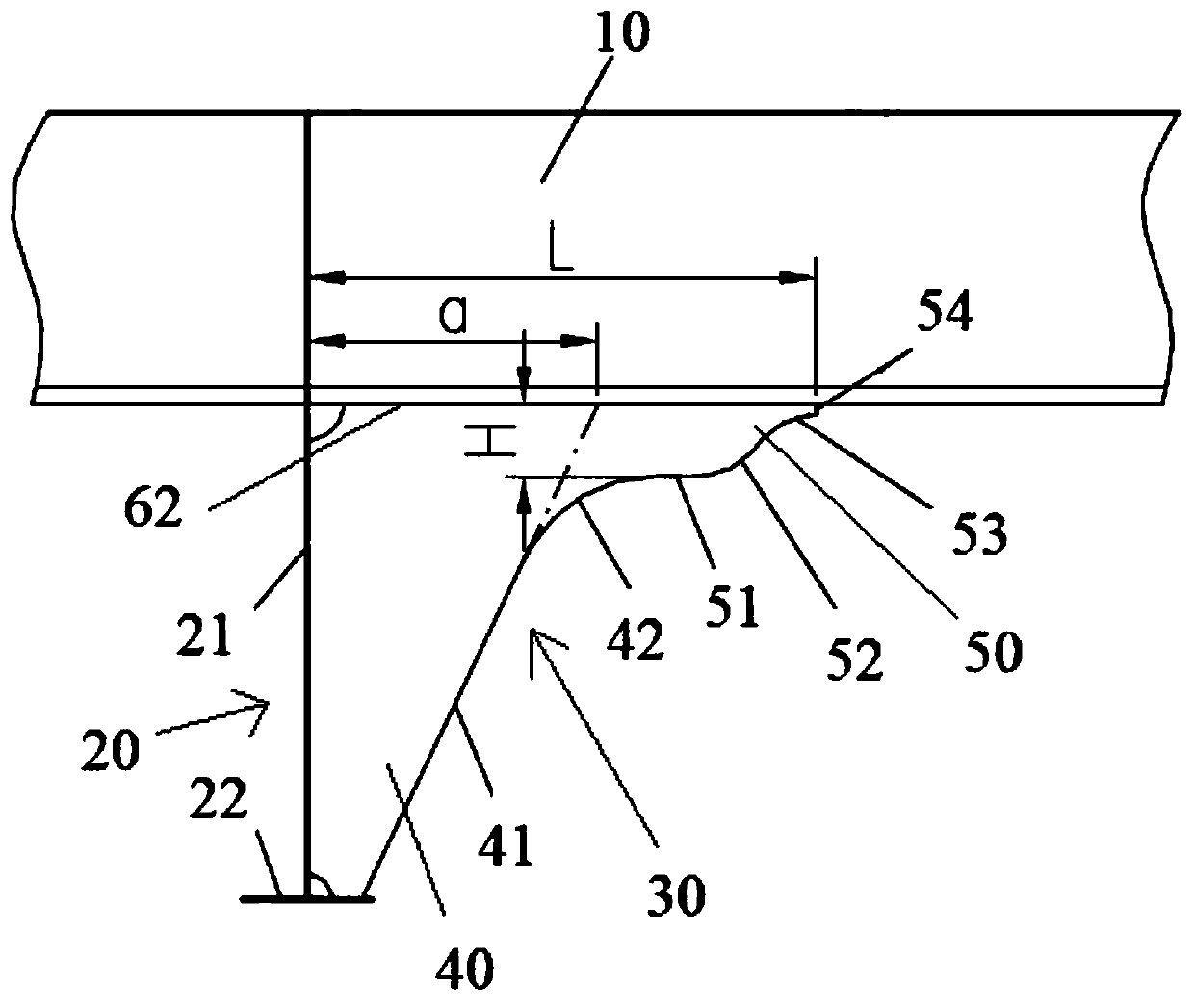

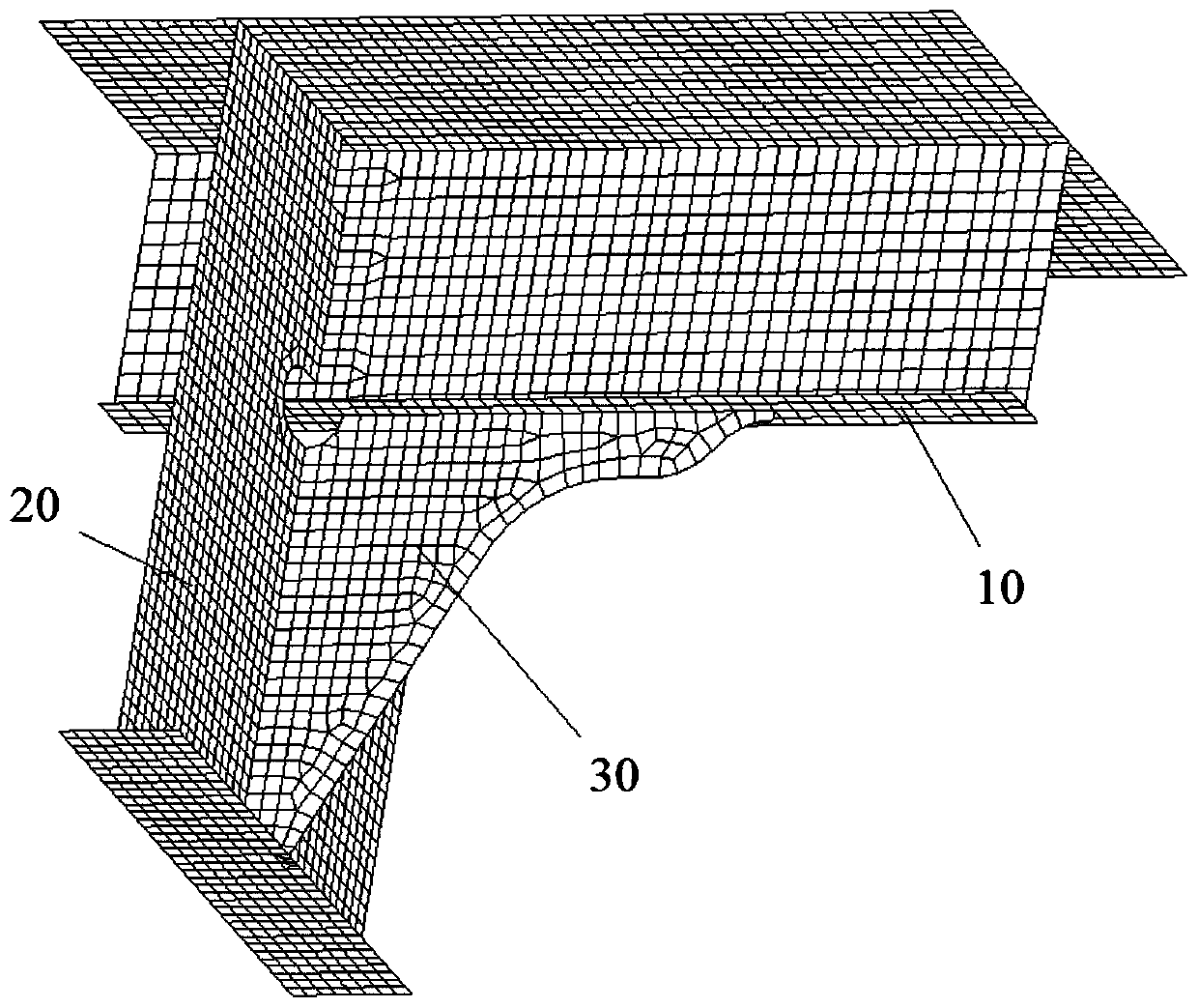

[0020] like figure 1 As shown, a connection structure at the end of the longitudinal frame of a bulk carrier includes connecting plates 30 respectively fixed to the deck longitudinals 10 and the transverse webs 20; the webs 21 of the transverse webs 20 are perpendicular to the deck longitudinals 10. The panel 22 of the transverse strong frame 20 is parallel to the deck longitudinal 10; the connecting plate 30 includes a plate body 40 and a toe end 50, the toe end 50 is connected to the plate body 40, and the plate body and the toe end are integrally formed.

[0021] The free side of the board body 40 includes a first board body side 41 and a second board body side 42 connected in sequence.

[0022] The free side of the toe end 50 includes a first toe end edge 51 , a second toe end edge 52 , a third toe end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com