Footwear heel

A heel and reinforcing core technology, which is applied in the direction of heels, heel pads, footwear, etc., can solve the problems of losing the slenderness of high heels and affecting the portability of heels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

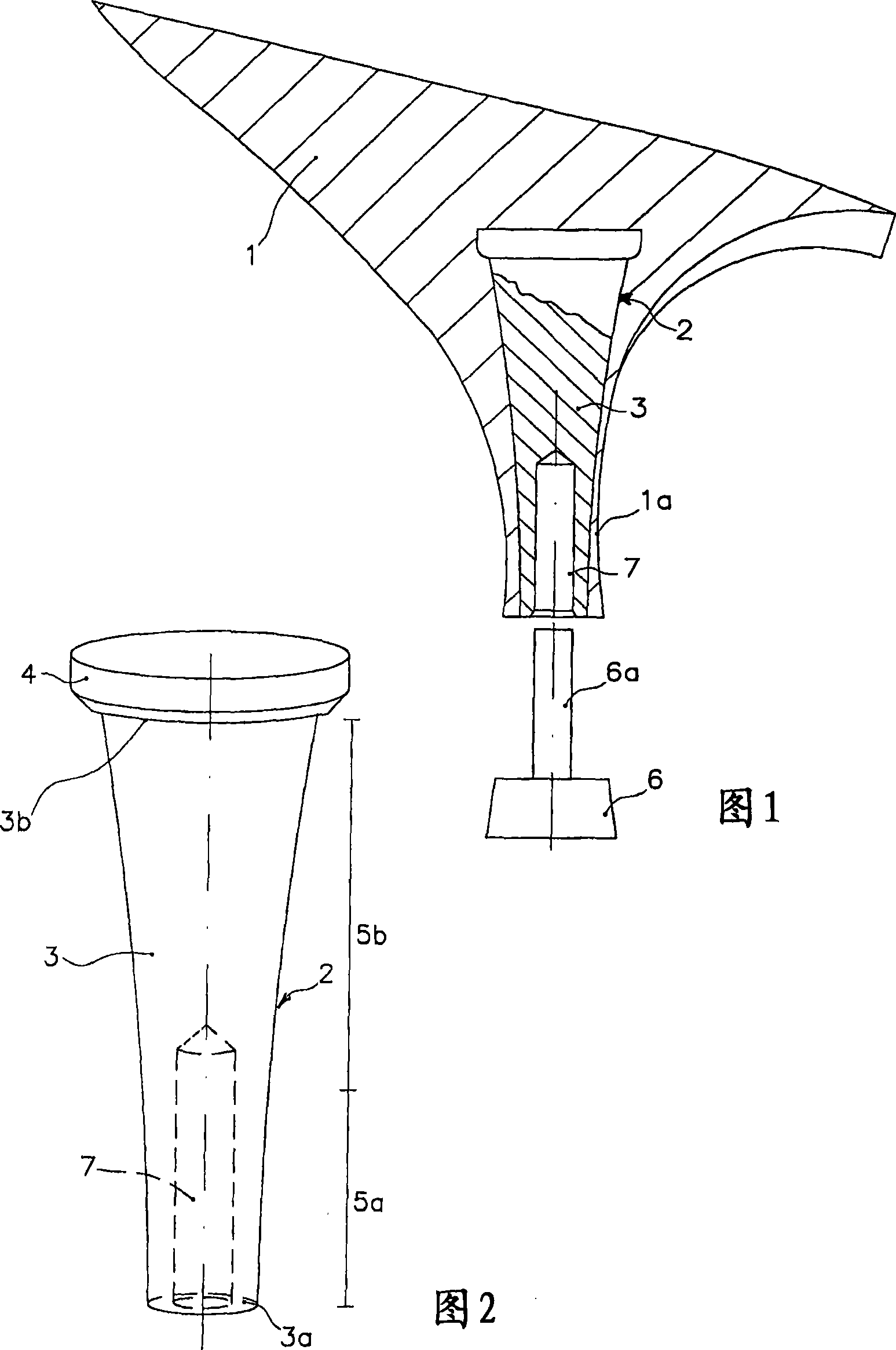

[0010] With reference to the aforementioned figures, reference numeral 1 designates the body of the stiletto heel obtained by injection molding in a conventional manner, and reference numeral 2 designates the reinforcing core contained in its elongated support portion 1a during the injection molding manufacturing process.

[0011] The reinforcing core 2 comprises a shank 3 of generally frusto-conical section terminating in a head 4 of larger cross-section. The stem 3 has a length and section suitable to allow it to fit into a thin heel of conventional dimensions.

[0012] The core 2 expands from the lower end 3a of the rod 3, and its first rod-shaped portion 5a has a very small taper, and the first rod-shaped portion 5a gradually transitions to a second rod-shaped portion 5b with a radius. The rod-shaped portion 5b has a relatively large taper. The head 4 extends from the upper end 3 b of the shaft 3 .

[0013] It is very important that the shank portions 5a and 5b with diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com