Slurry-scraping equipment with preheating function

A technology of equipment and functions, applied in the field of scraping equipment with preheating function, can solve the problems of no preheating and shaping, the slurry cannot be cleaned in time, and the scraping effect is poor, and the effect of improving the scraping effect can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

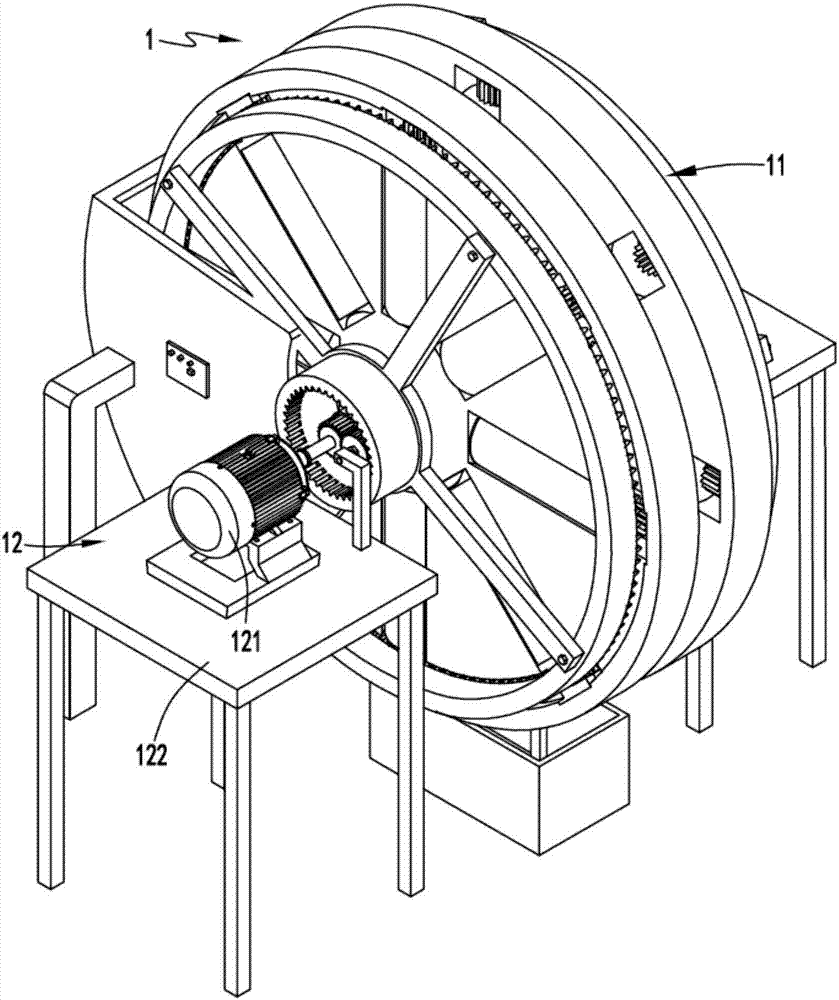

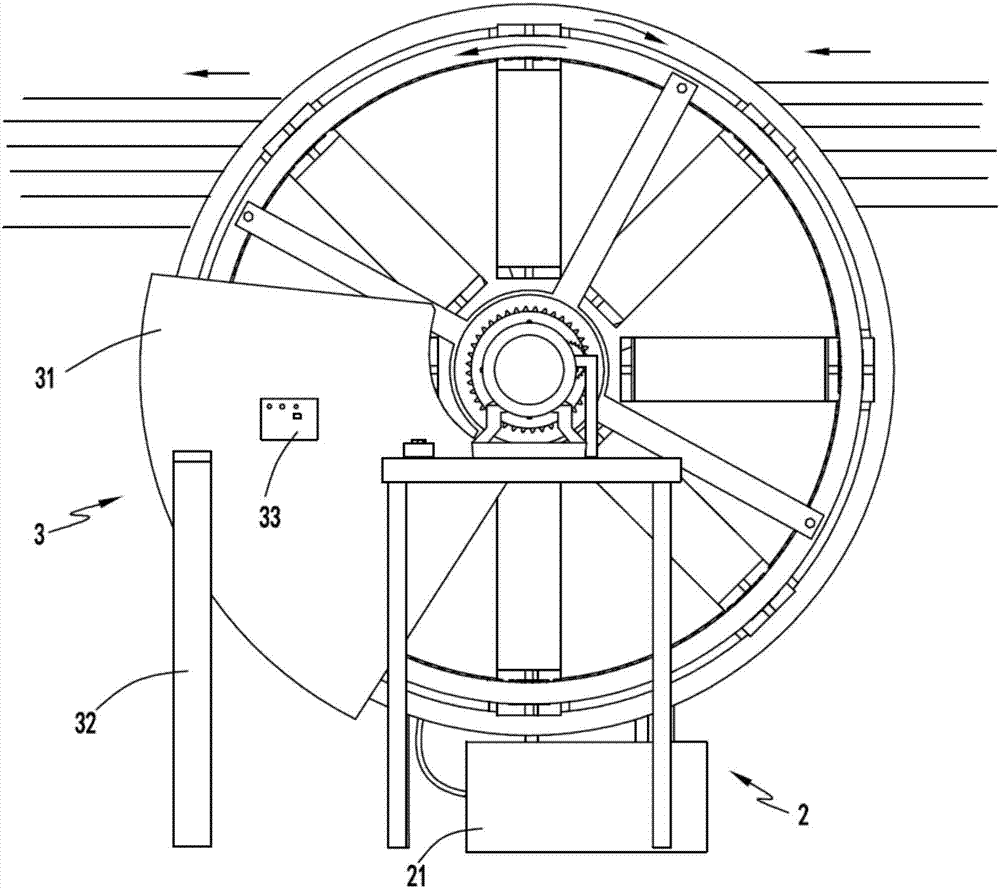

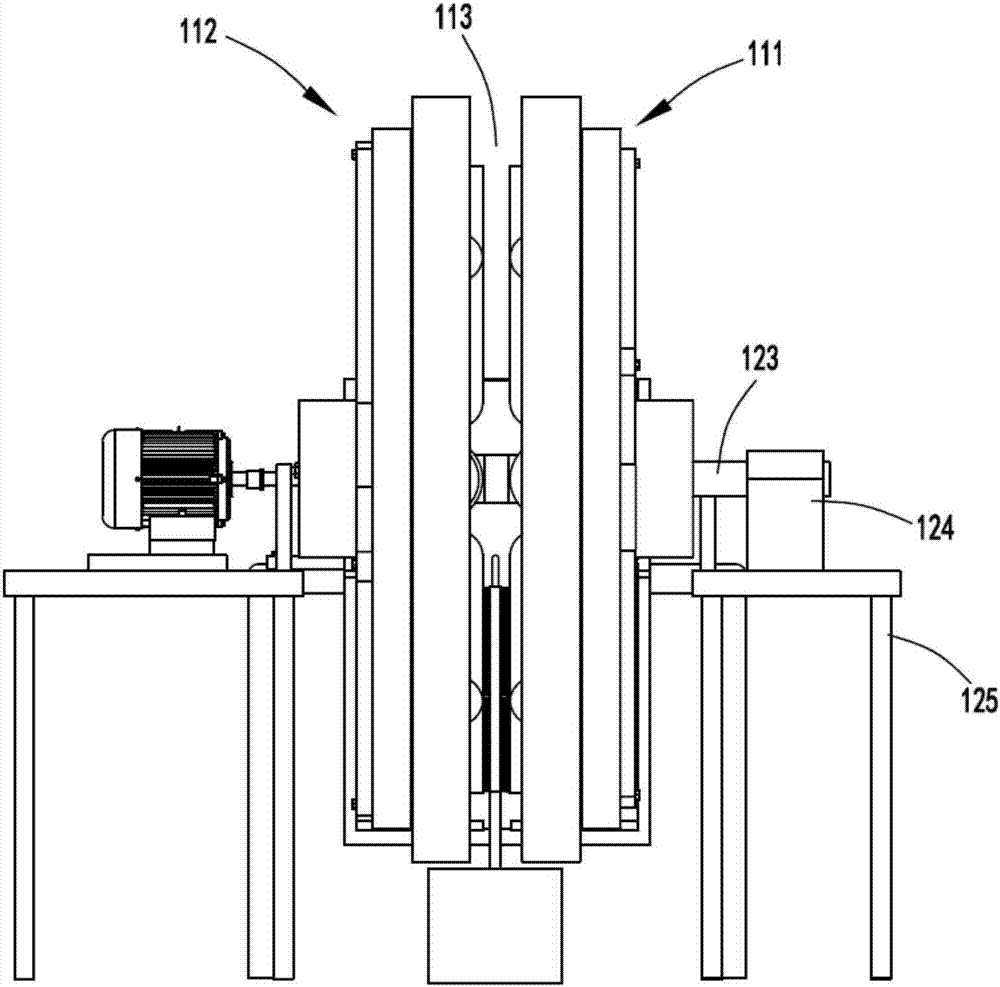

[0035] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 As shown in Figure 8, a squeegee device with a preheating function includes a squeegee part 1, and the squeegee part 1 includes a squeegee mechanism 11 and a drive mechanism 12 arranged on one side of the squeegee mechanism 11. The driving mechanism 12 is used to drive the squeegee mechanism 11 to squeegee and pre-dry the warp yarns passing through while rotating;

[0036] The cleaning part 2, the cleaning part 2 is arranged in the scraping mechanism 11, the cleaning part 2 includes a water collecting tank 21 and a cleaning mechanism 22 arranged above the water collecting tank 21, and the cleaning mechanism 22 is used to complete the cleaning in the scraping mechanism 11. During the process of scraping and continuing to rotate, spray water to clean the surface;

[0037] And a drying part 3, the drying part 3 is arranged on the rotation path of the squeegee mechanism 11 and behind ...

Embodiment 2

[0047] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 and Figure 8 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is that the cleaning mechanism 22 includes a conduit 221 communicating with the inside of the water collecting tank 21 and a cleaning member 222 communicating with the conduit, and the cleaning member 222 includes a 21 on the cleaning plate 2221, the surface of the cleaning plate 2221 is provided with several brushes 2222 and the interval between the brushes 2222 and the brushes 2222 is provided with several water spray holes 2223, and the brushes 2222 are used for scraping Clean the slurry slag on the roller 11132, and the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com