A multi-gear air pressure limit structure for automobiles

A limit structure and multi-gear technology, applied in the field of car body, can solve the problems of insufficient elastic force of metal elastic body, independent limiter occupying installation space, affecting movement space and stability, etc., to reduce requirements, increase sheet metal and The number of related processes and the effect of optimizing the vehicle space design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The technical solution of the present invention is described in detail below through the examples, and the following examples are only exemplary and can only be used to explain and illustrate the technical solution of the present invention, rather than being interpreted as a limitation to the technical solution of the present invention.

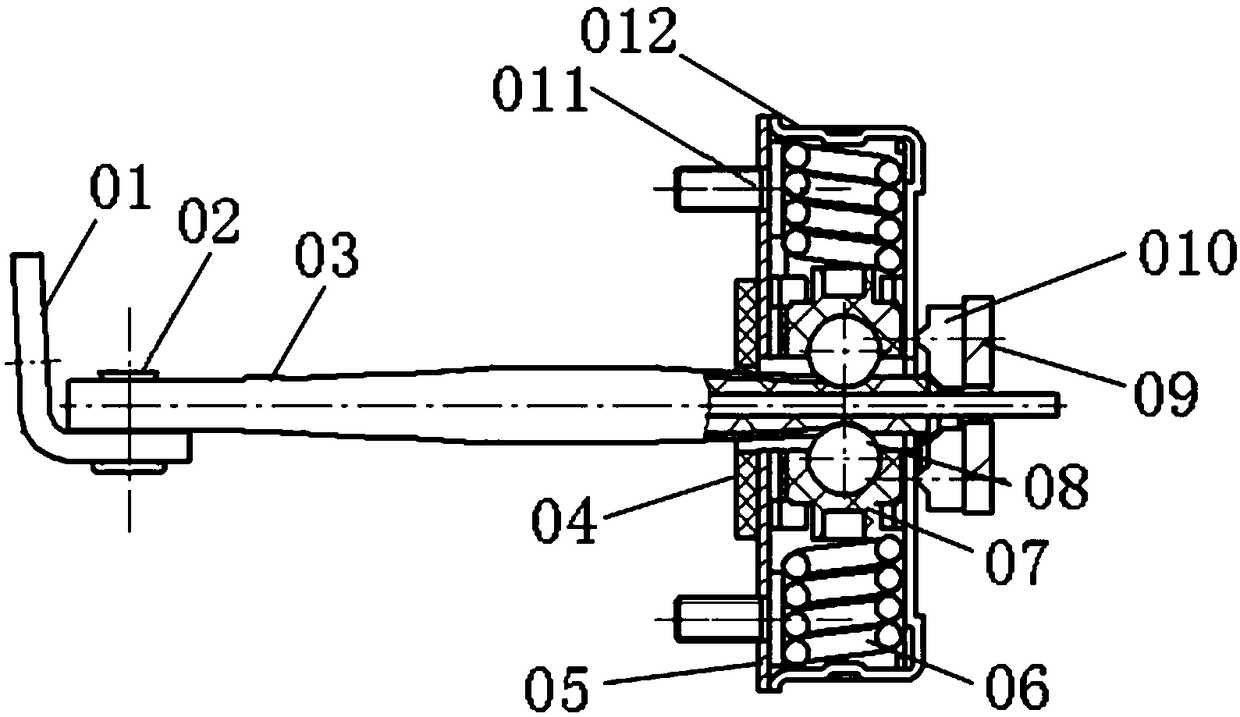

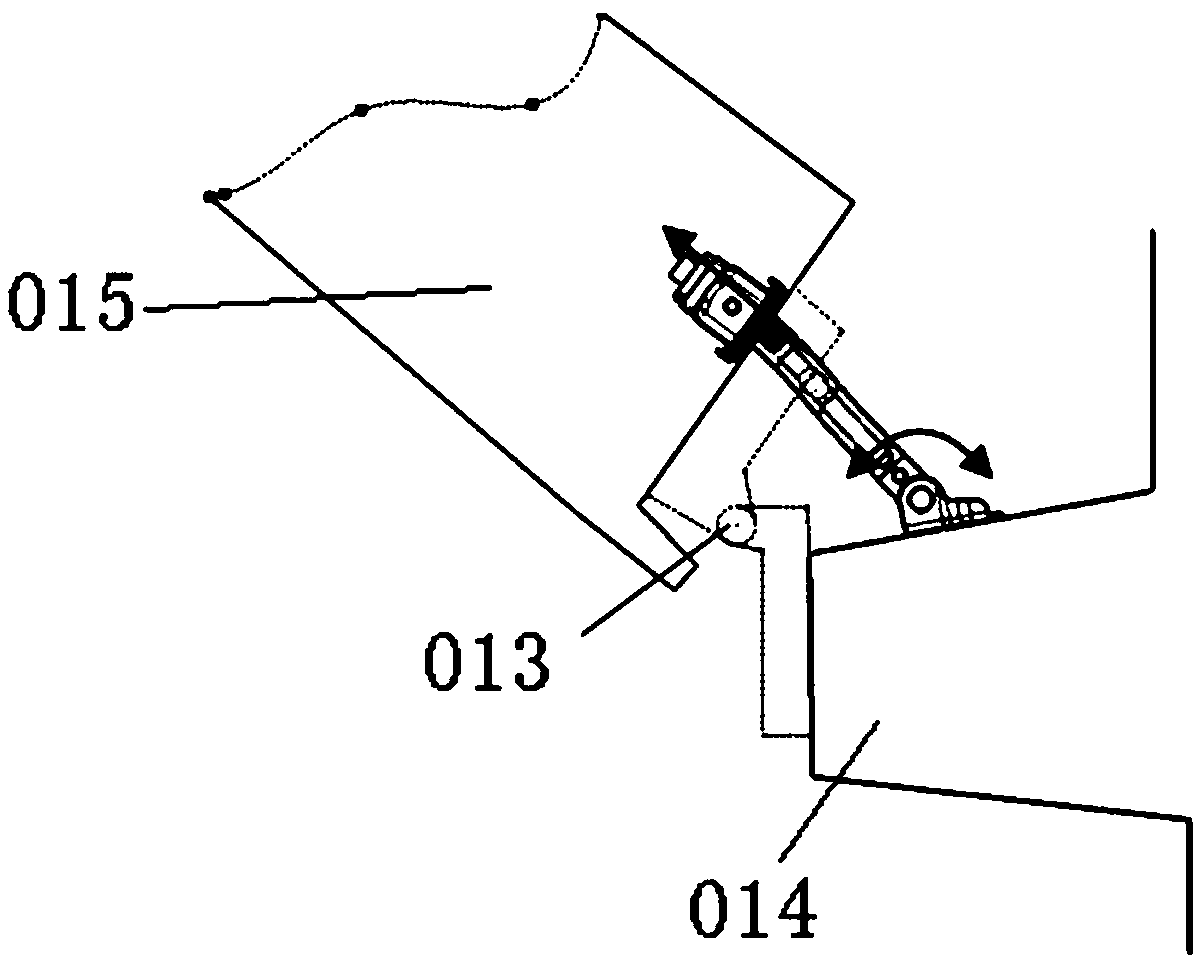

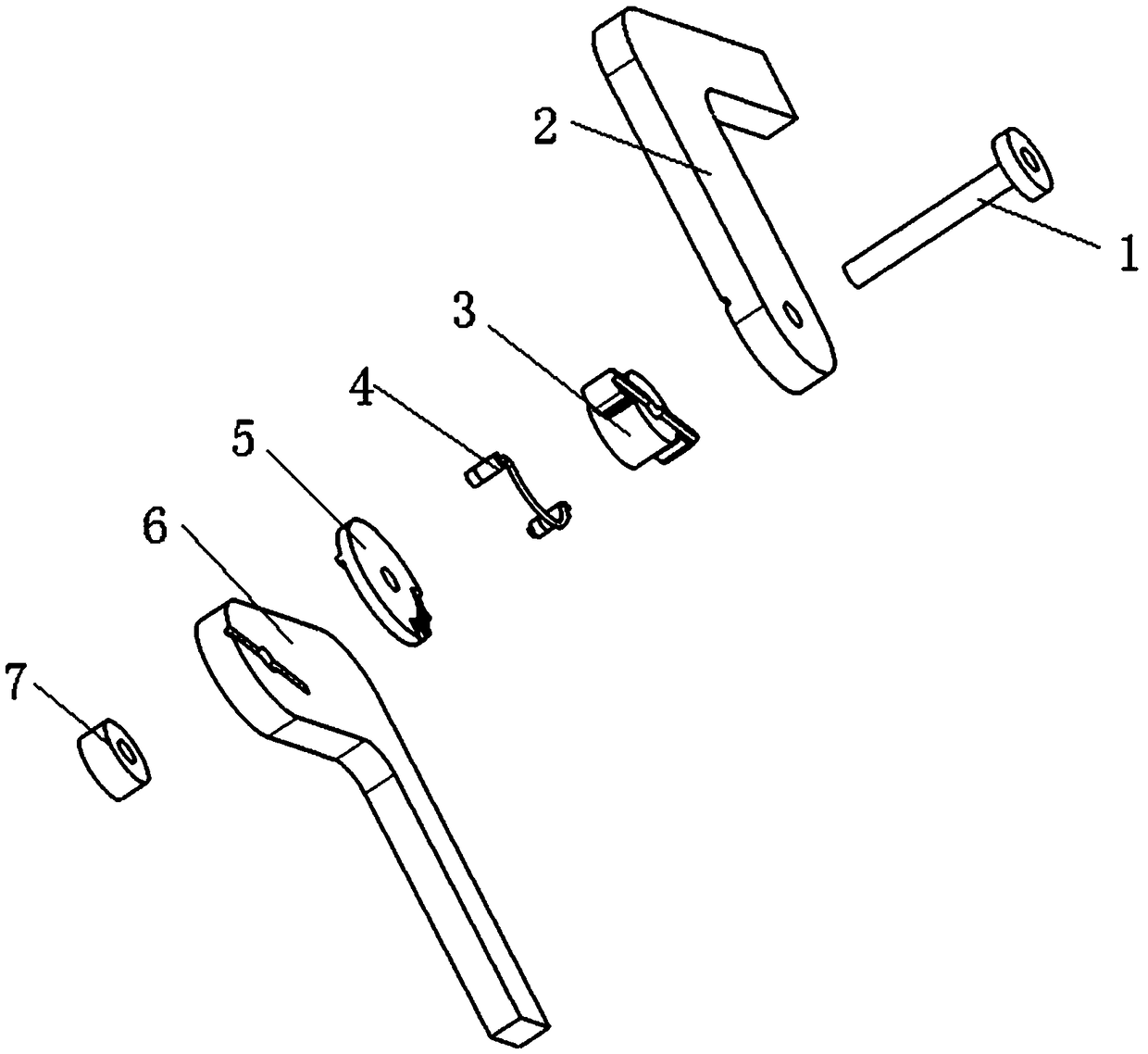

[0042] This application provides a multi-gear air pressure limit structure for automobiles, such as Figure 3 to Figure 11 As shown, it includes a shaft 1 , a first blade 2 , an elastic support 3 , an elastic output assembly 4 , a limiting disk 5 , a second blade 6 and a fastening nut 7 .

[0043] The first fan blade is provided with a first fan blade through hole, and the surface of the first fan blade in contact with the elastic support is provided with a first limiting groove. In this application, the cross section of the first limiting groove is trapezoidal.

[0044] The elastic support 3 includes a cylindrical elastic support bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com