Light guide component and automobile lamp having same

A component and light guide technology, applied in the field of vehicle lighting, can solve the problems of large installation error, high cost of a single PCB, insufficient uniformity, etc., to achieve uniform brightness, uniform lighting effect, and reduce impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The advantages of the present invention are further described below with reference to the accompanying drawings and specific embodiments.

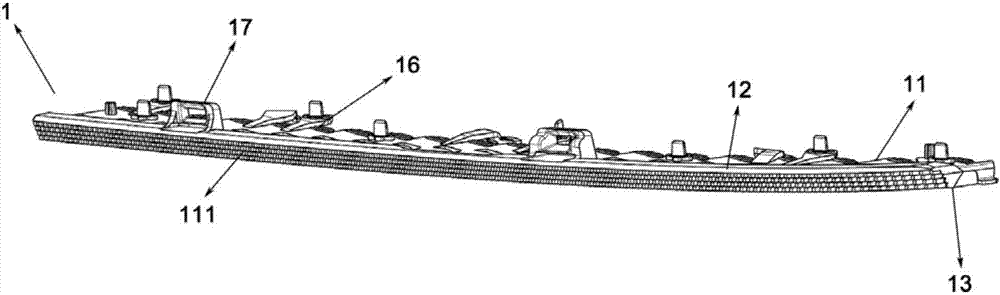

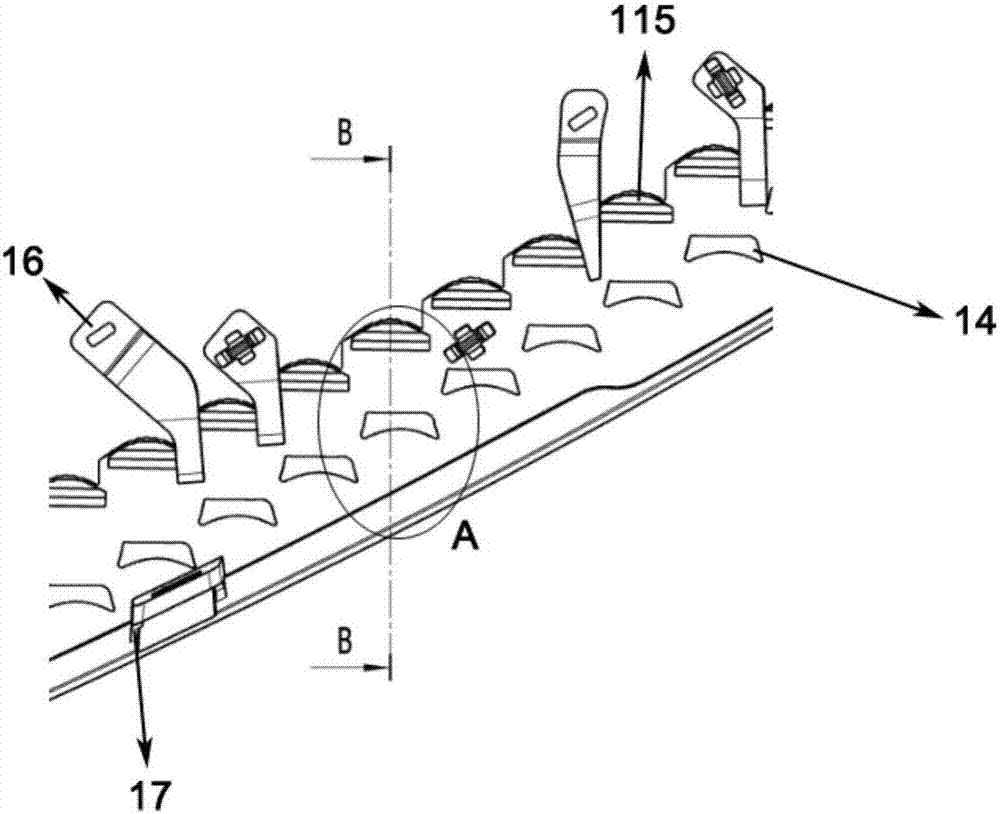

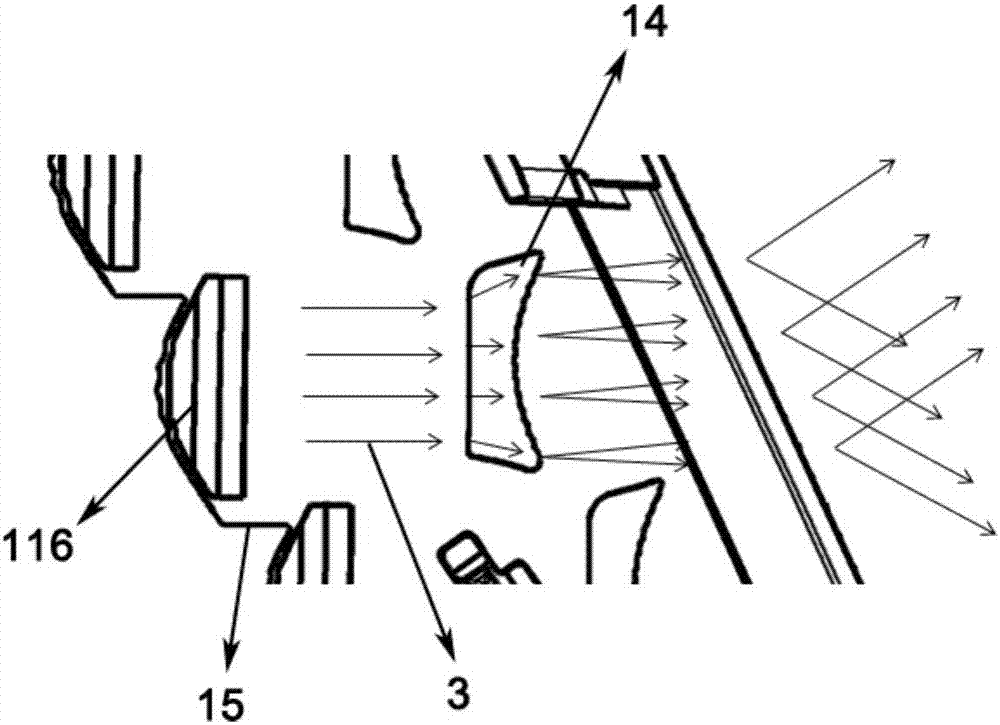

[0041] like Figure 1 to Figure 6 As shown, the light guide member 1 according to the preferred embodiment of the present invention, used for vehicle headlight and taillight lighting, includes at least one optical unit 11, and each optical unit 11 is arranged next to each other along the horizontal extension direction of the light guide member 1, or it can be It is an integrally formed structure, including the front optical surface 111, the rear optical surface 112, the upper surface 113 and the lower surface 114. The upper surface 113 and the lower surface 114 of each optical unit 11 are flush and continuously connected to form a flat light guide member The upper interface 12 and the lower interface 13 of 1, in some embodiments, the upper interface 12 and the lower interface 13 are formed by a plurality of upper surfaces 113 and T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com