Precise pipe cutting mechanism

A pipe cutting and precision technology, applied in the direction of pipe shearing device, shearing device, shearing machine equipment, etc., can solve the problems of narrow pipe diameter range, limited adjustment range, poor versatility, etc., and achieve the effect of strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to describe in detail the technical content, structural features, objectives and effects of a precision close tube mechanism of the present invention, the following will be further described in conjunction with the embodiments and accompanying drawings.

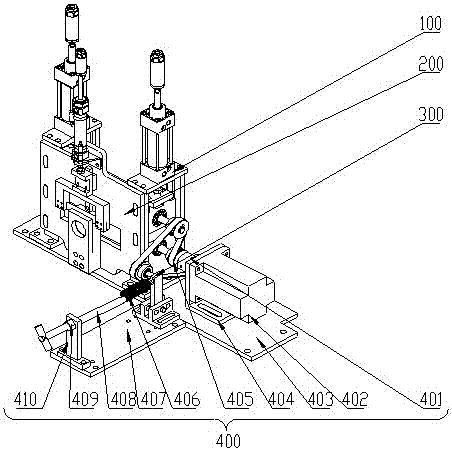

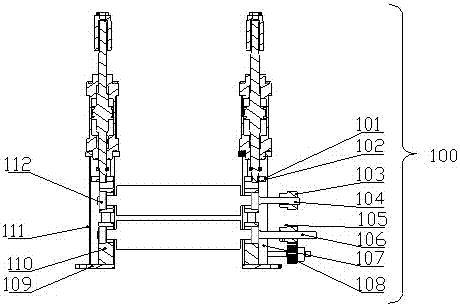

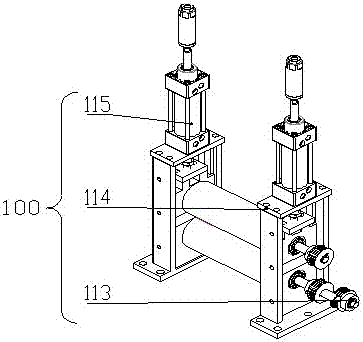

[0034] like Figure 1 to Figure 6 As shown, this group of figures discloses an embodiment of a precision close tube mechanism of the present invention. This example includes: a pulling mechanism 100, a cutter mechanism 200, a tensioning mechanism 300, and a power mechanism 400; the pulling mechanism 100 passes through a gantry crane The base 109 and the base plate 403 of the power mechanism 400 are connected and fixed as a whole, and the roller shaft B 106 of the traction mechanism 100 is connected with the servo motor 402 through the shaft coupling 401 of the power mechanism 400; The vertical installation base plate 204 is connected and fixed as a whole with the left gantry crane type cylinder 111 and the rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com