Sweet potato shredding machine

A technology of shredding machine and sweet potato, applied in metal processing and other directions, can solve the problems of efficiency discount, low efficiency, high labor intensity, etc., and achieve the effect of reducing the possibility of jamming, reliable and convenient use, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in further detail by specific embodiment now in conjunction with accompanying drawing:

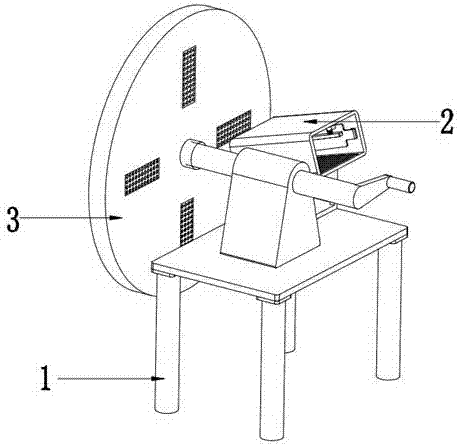

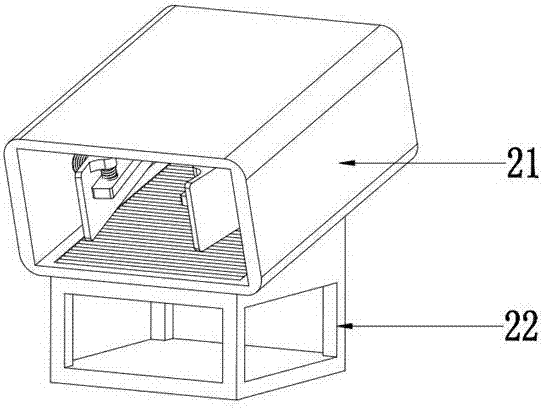

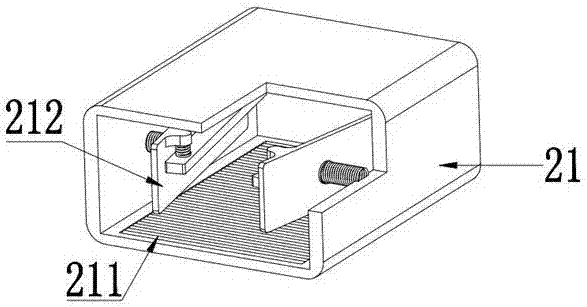

[0025] like Figure 1 to Figure 7 Shown, a kind of shredded sweet potato machine, described sweet potato shredded machine comprises base 1, material guide trough 2, rotary disc cutter 3; Described base 1, above is a rectangular support plate, four corners of support plate are provided with There are four backing plates, and the cylinder is connected under the backing plate; the material guide groove 2 is installed on the surface of the base 1, and the material guide groove is divided into a support 21 and a material guide port 22, and the material guide port 22 is installed on the support 21; the rotary disc cutter 3 is composed of a rotating shaft support 31, a handle 32, a rotating shaft 33, a rotating disc 34, and a thread cutter 35. The rotating shaft 33 is connected to the handle 32 and installed on the rotating shaft support 31, and the rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com