Patents

Literature

63results about How to "Less stuck" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

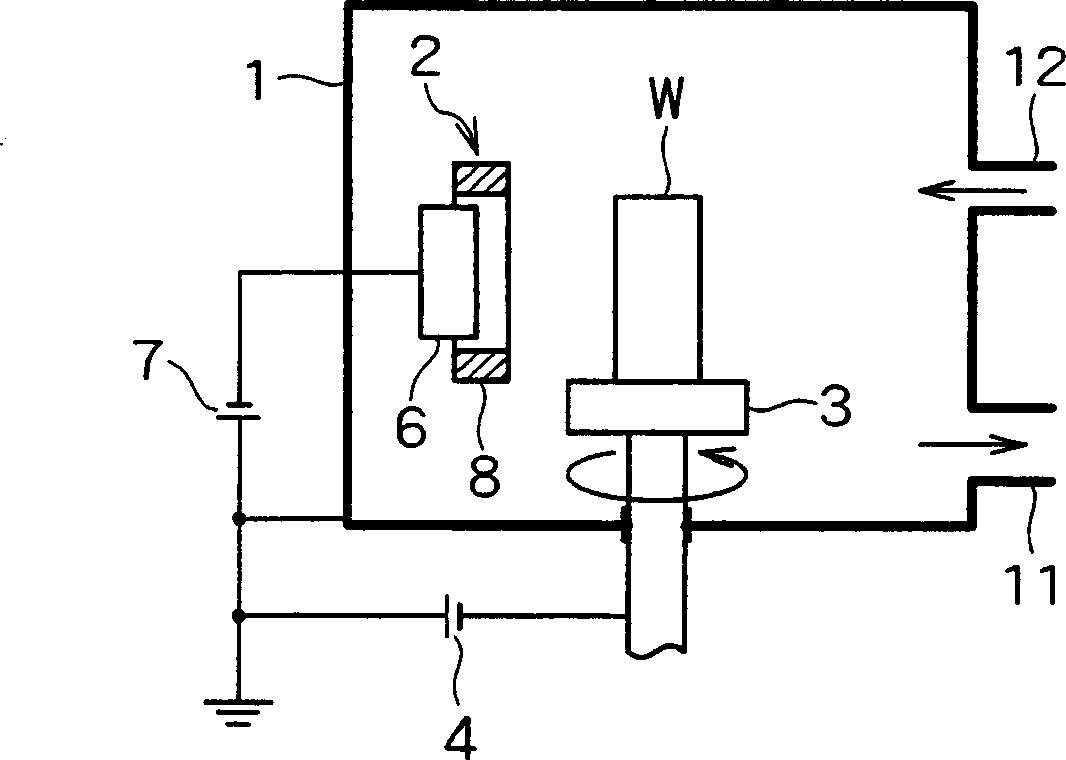

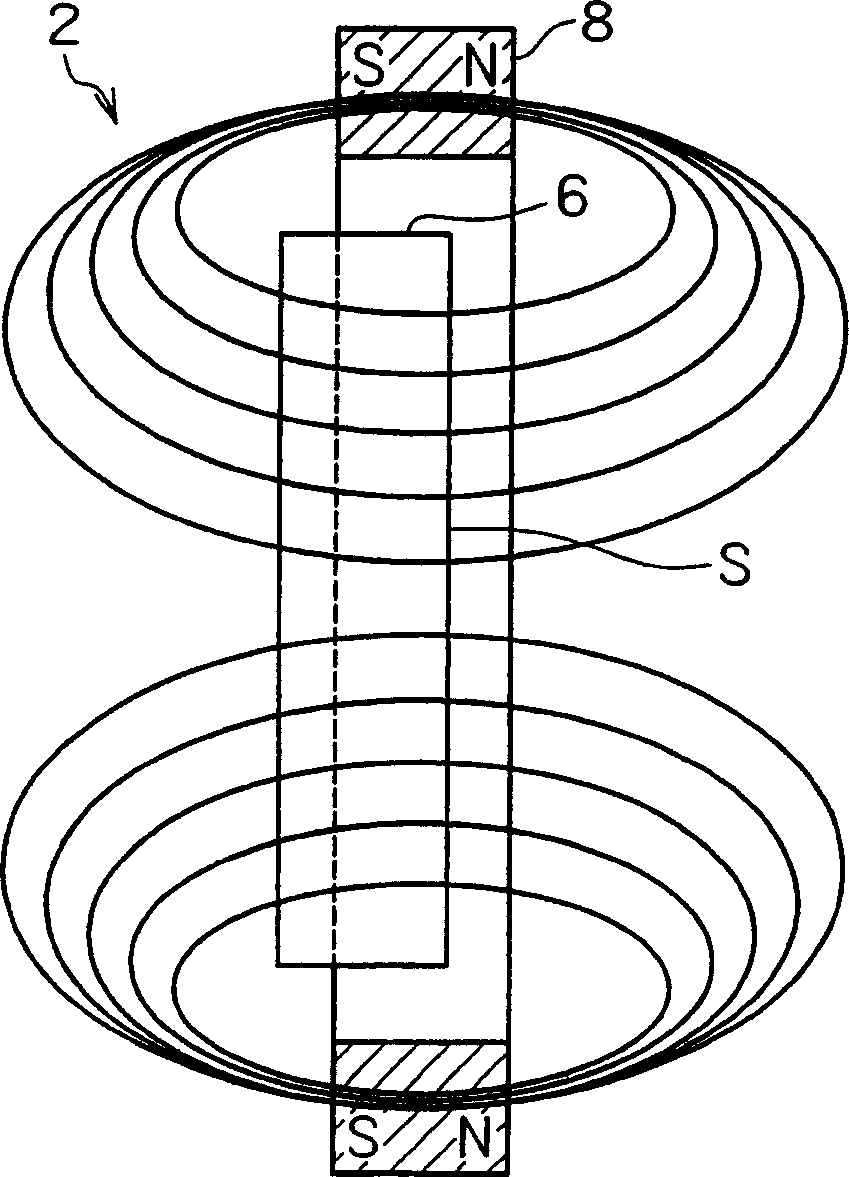

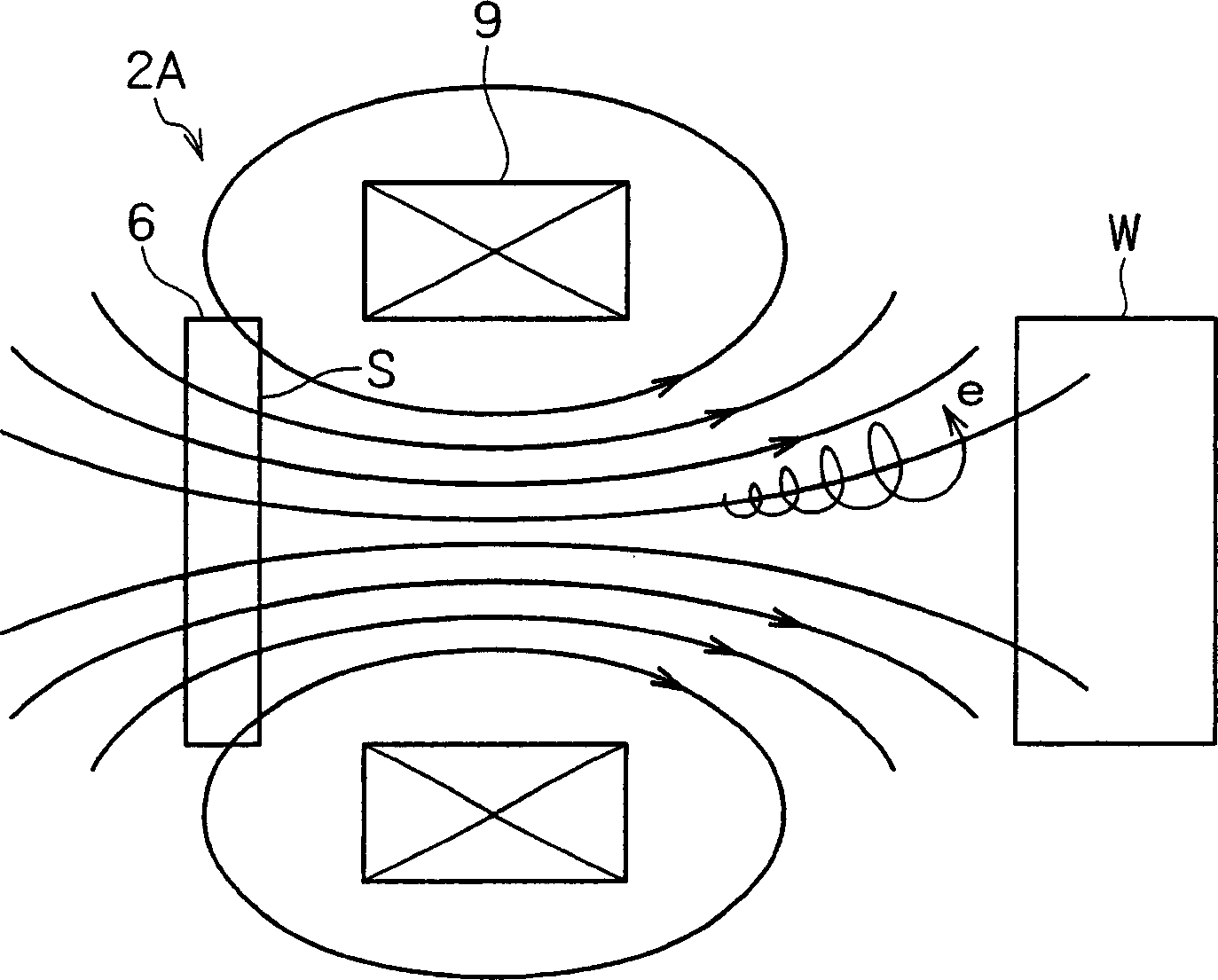

Hard coating, target for forming hard coating, and method for forming hard coating

InactiveCN1818125AExtended service lifeLess stuckVacuum evaporation coatingSputtering coatingHardnessMaterials science

Owner:KOBE STEEL LTD

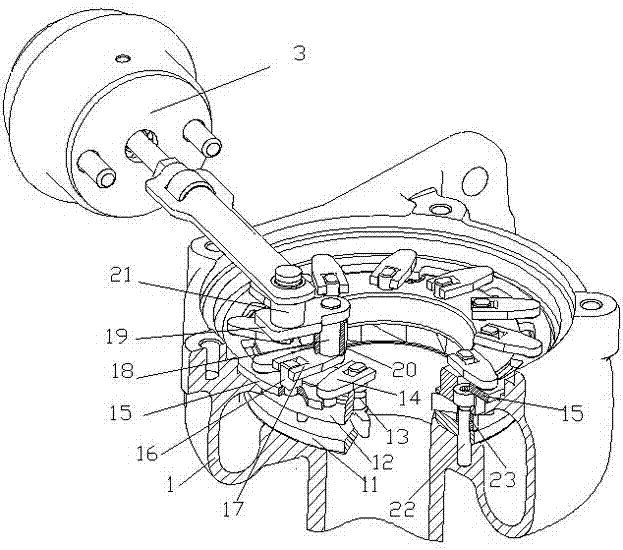

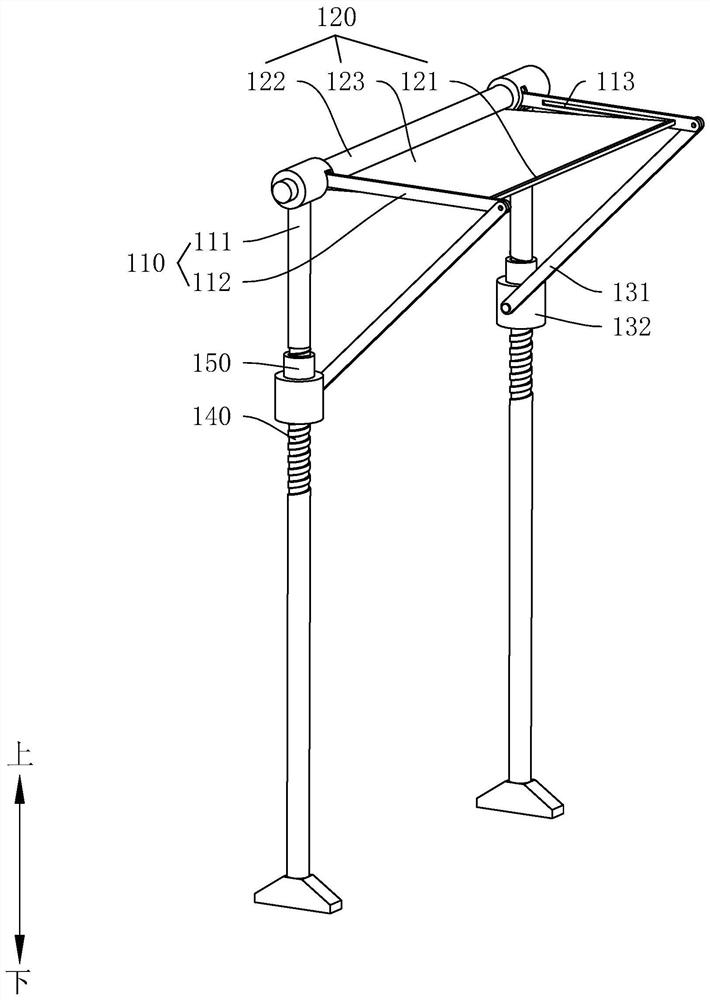

Spatial mechanism in three degrees of freedom in use for parallel-connected moving devices

InactiveCN101049698AImprove rigiditySimple structureProgramme-controlled manipulatorThree degrees of freedomDegrees of freedom

A 3-freedom space mechanism for the parallel moving apparatus (vibration sieve, entertainment system, machine-tool, robot, etc) is composed of a movable platform, a static platform, an ordinary branch, and a generalized branch consisting of 5 single-freedom moving sets and one rotary set. Said ordinary branch consists of two ball sets and one single-freedom moving set.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

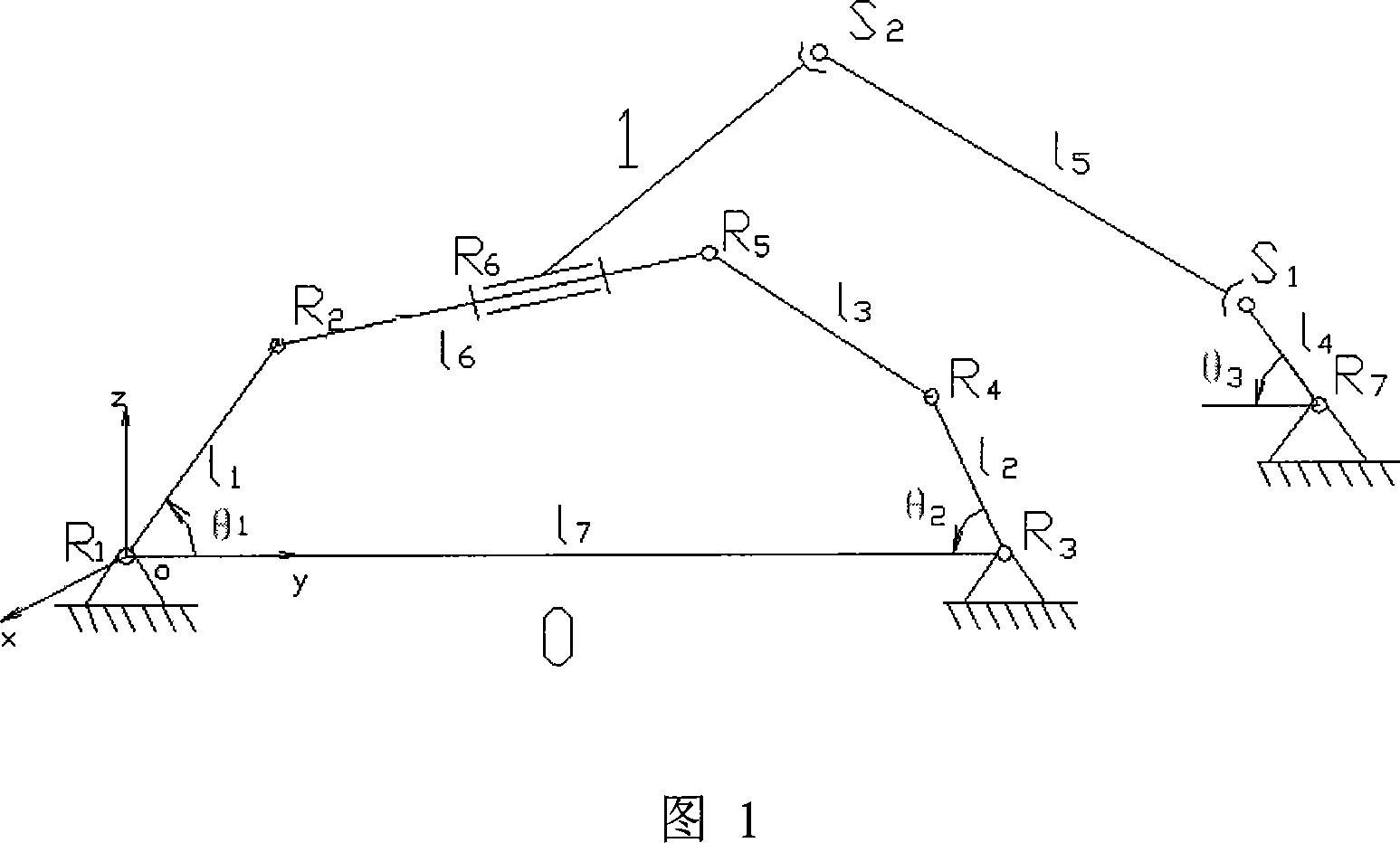

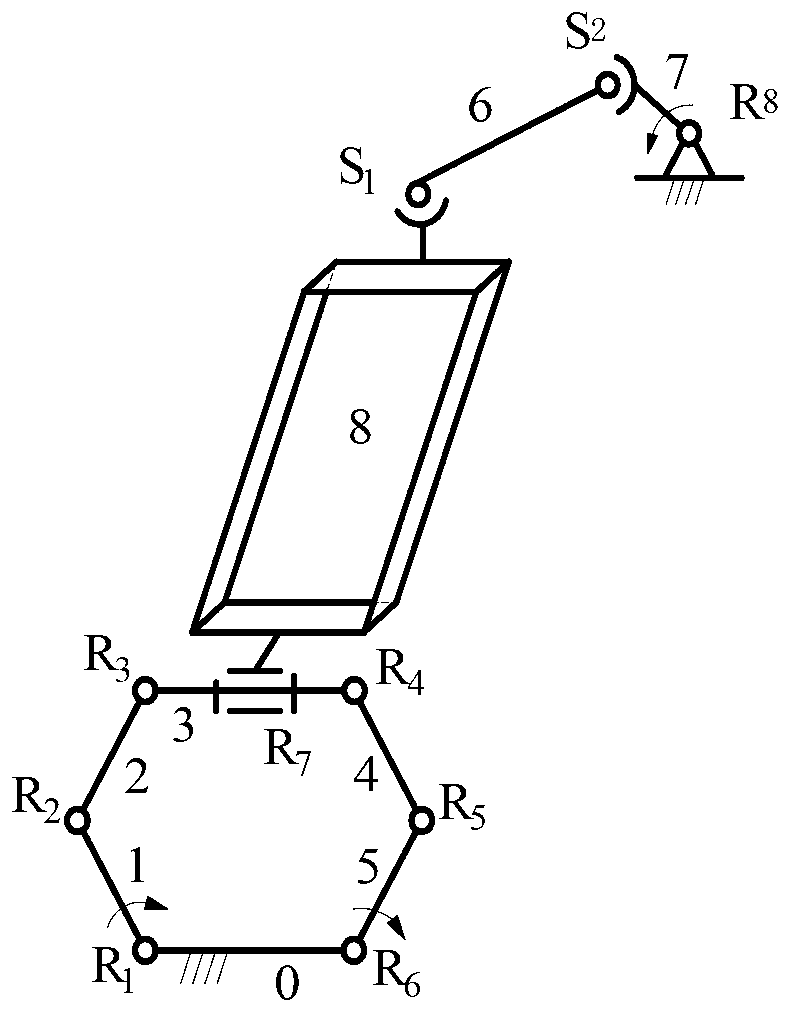

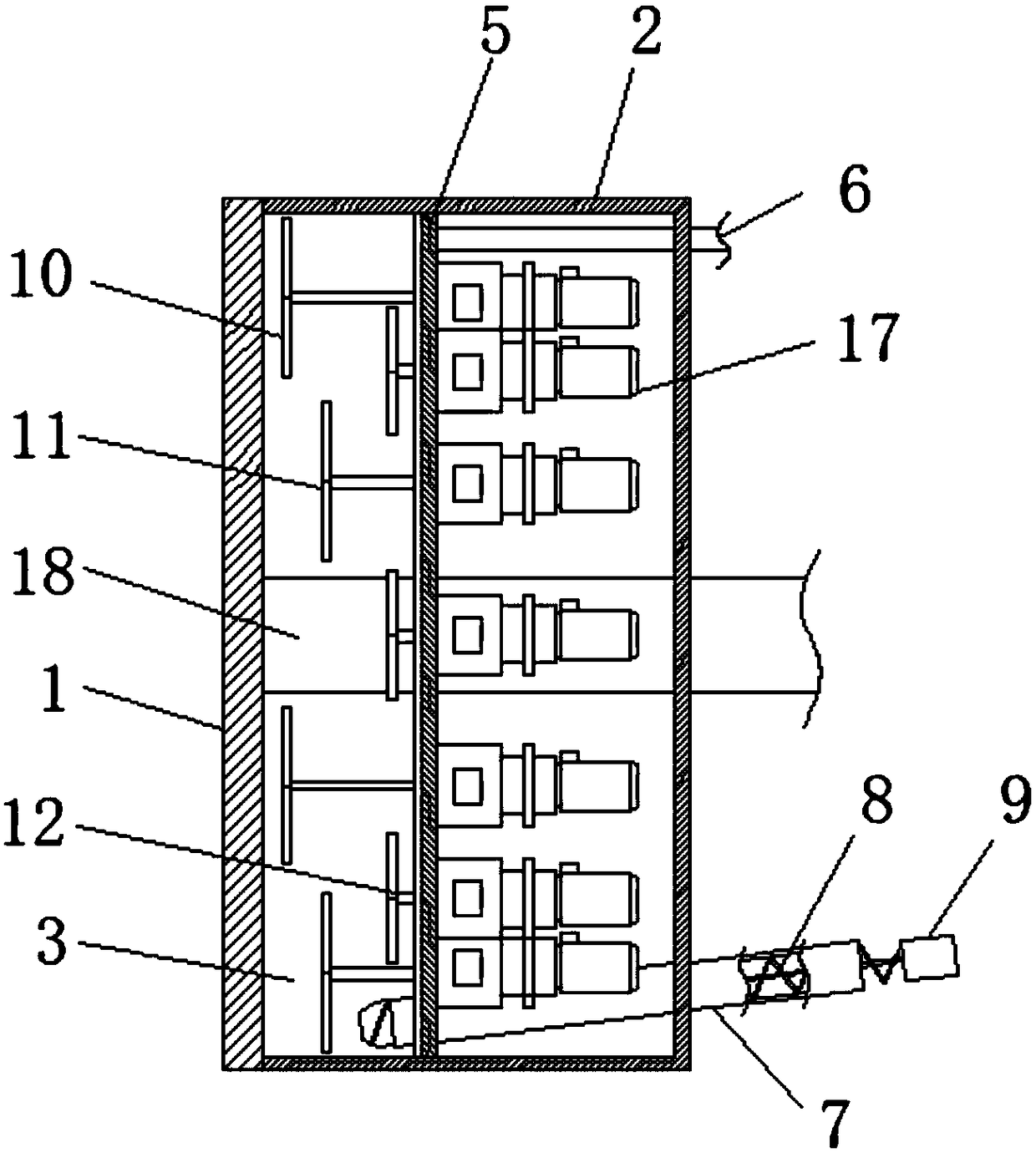

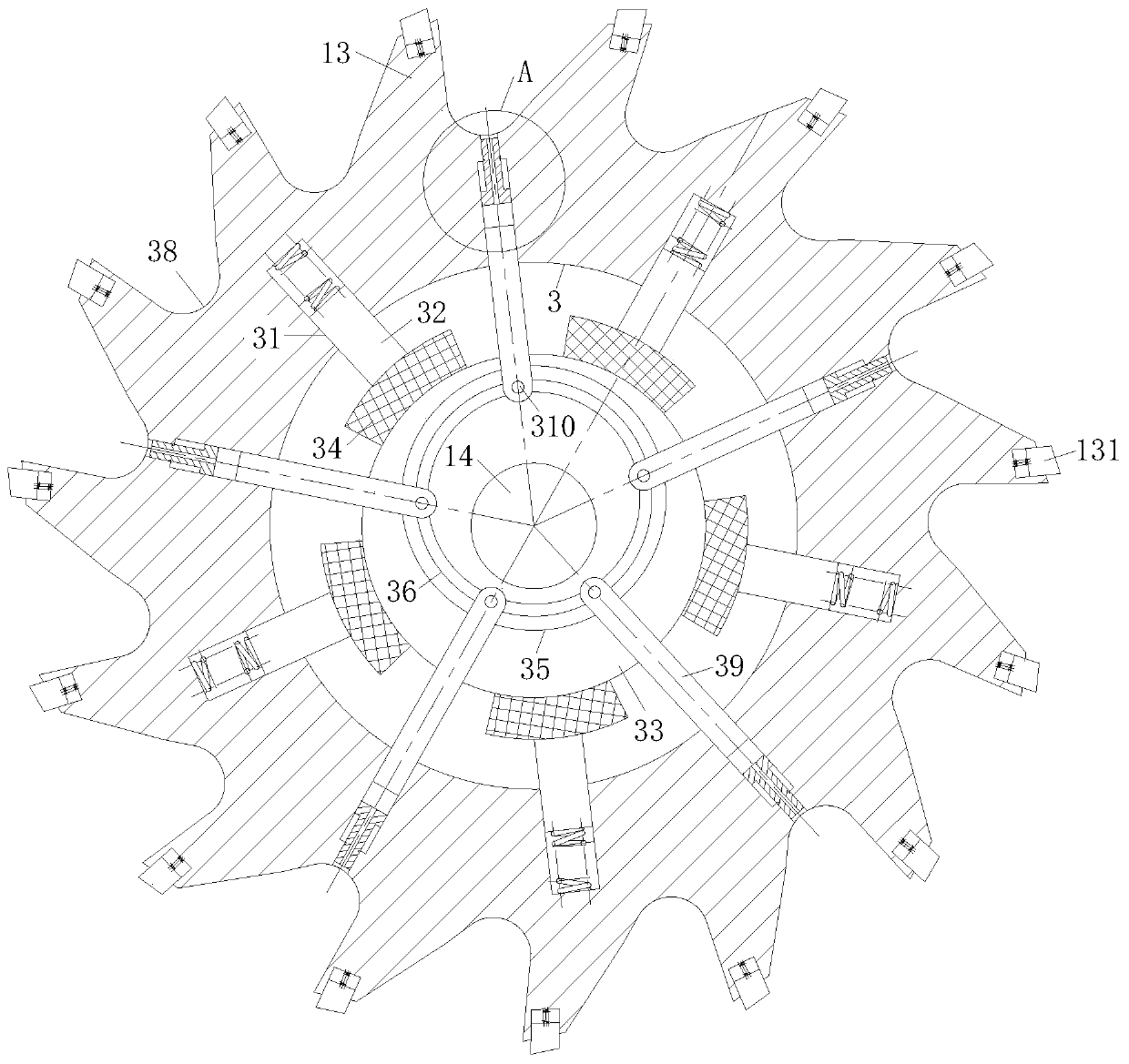

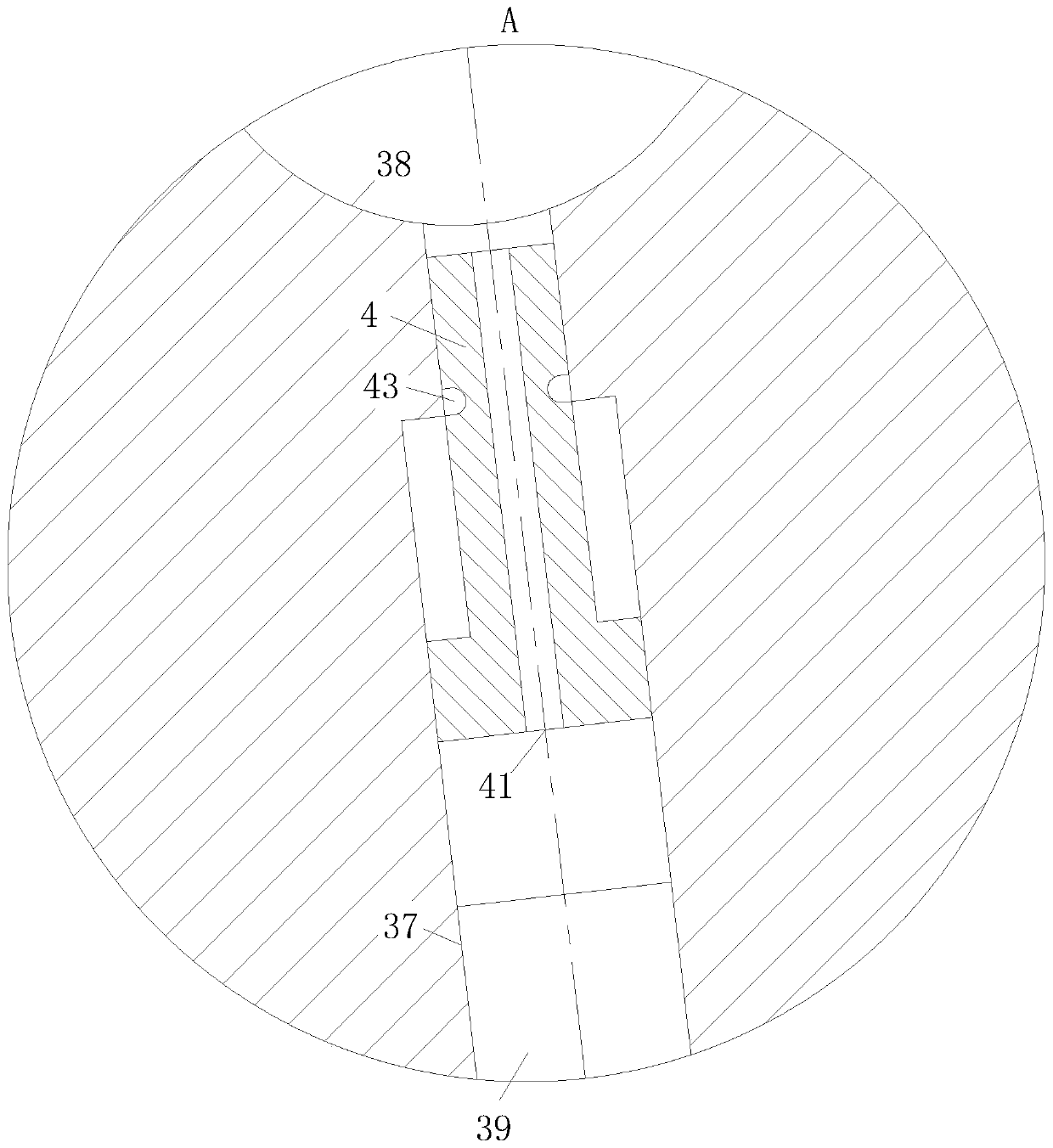

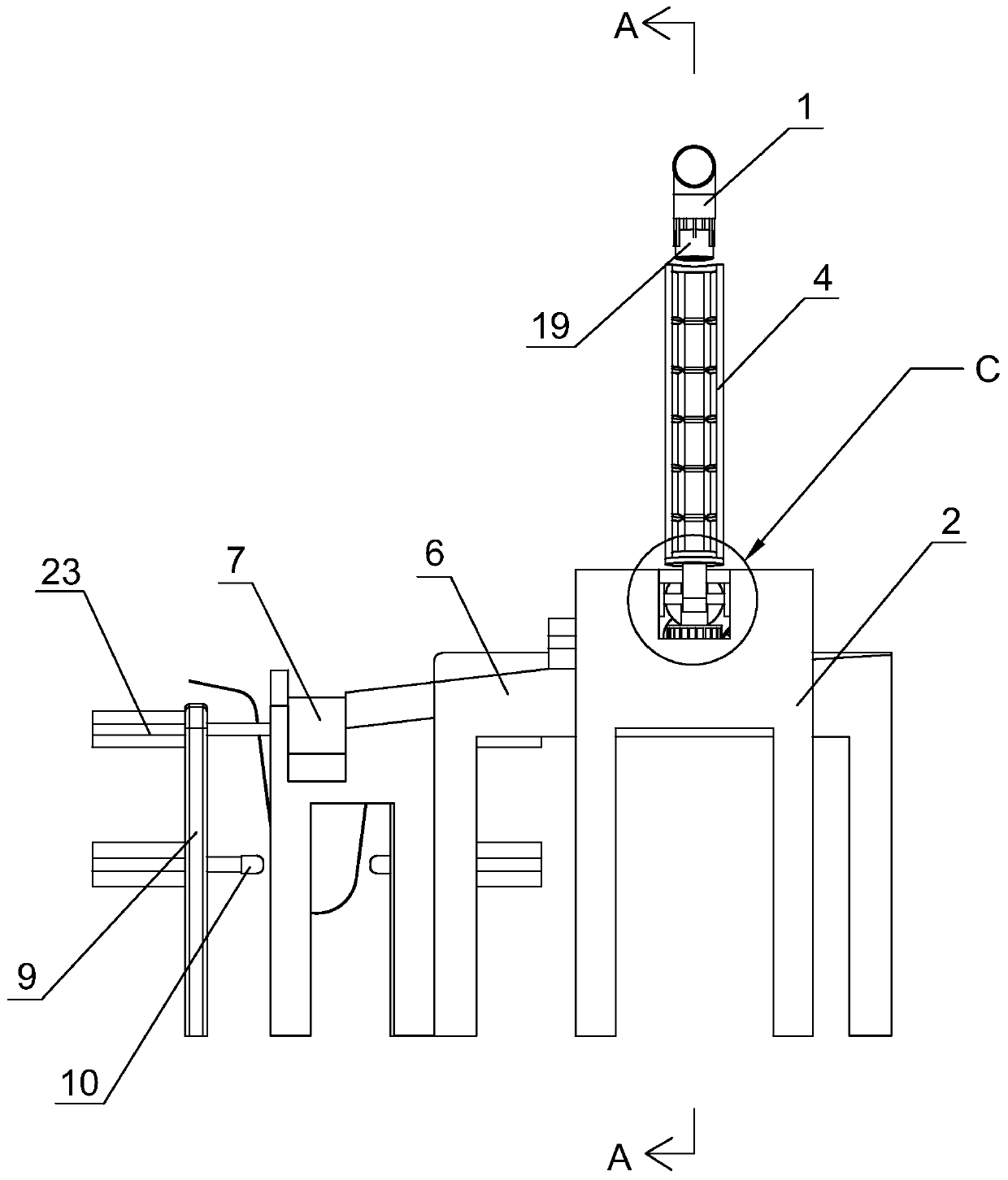

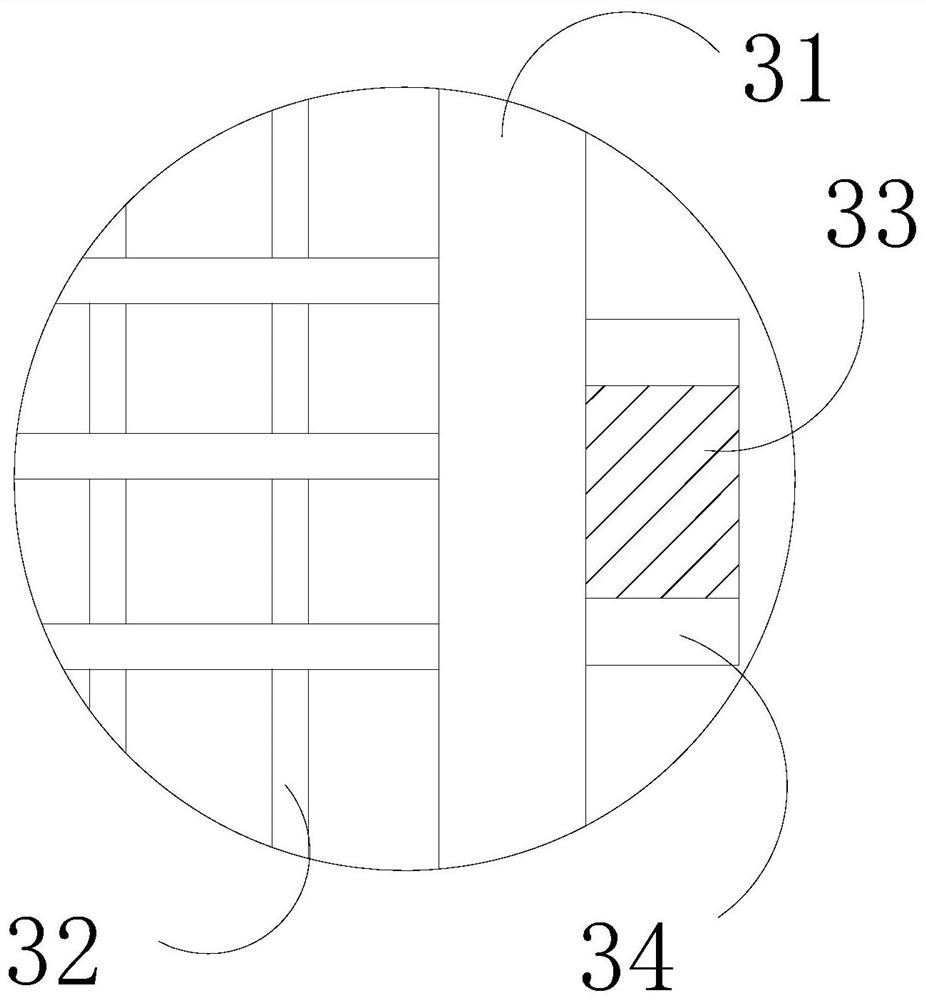

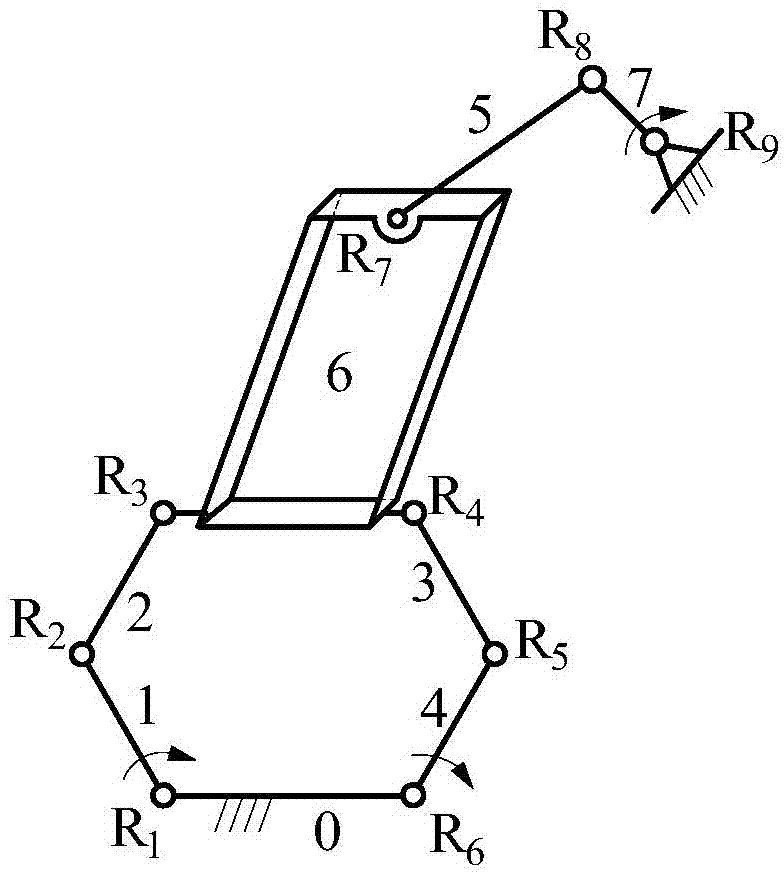

Variable-input three-dimensional spatial motion vibrating screen mechanism

InactiveCN103008232AImprove productivityLess stuckSievingScreeningThree-dimensional spaceEngineering

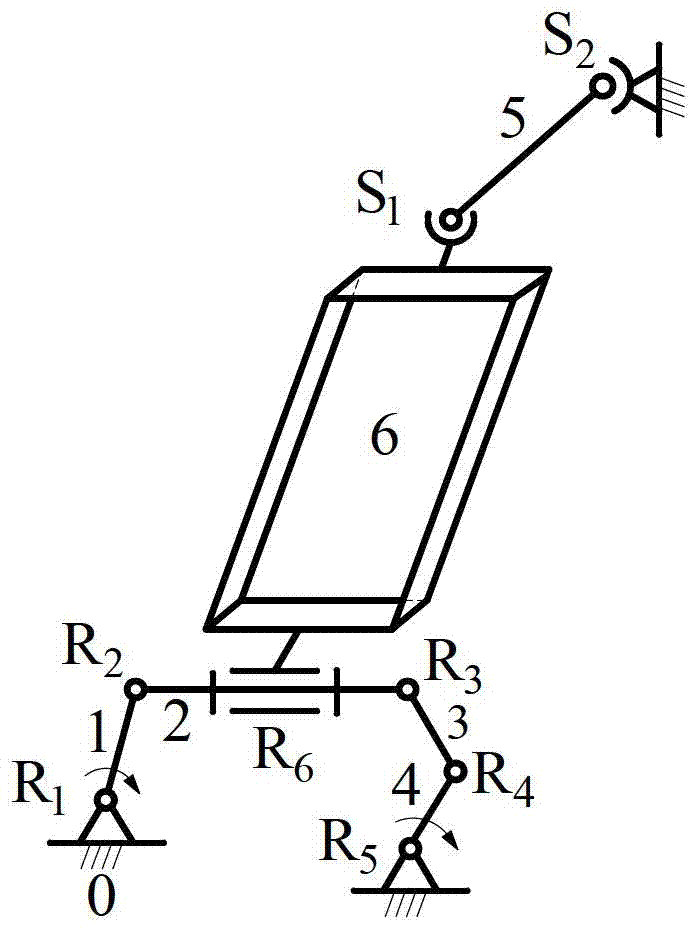

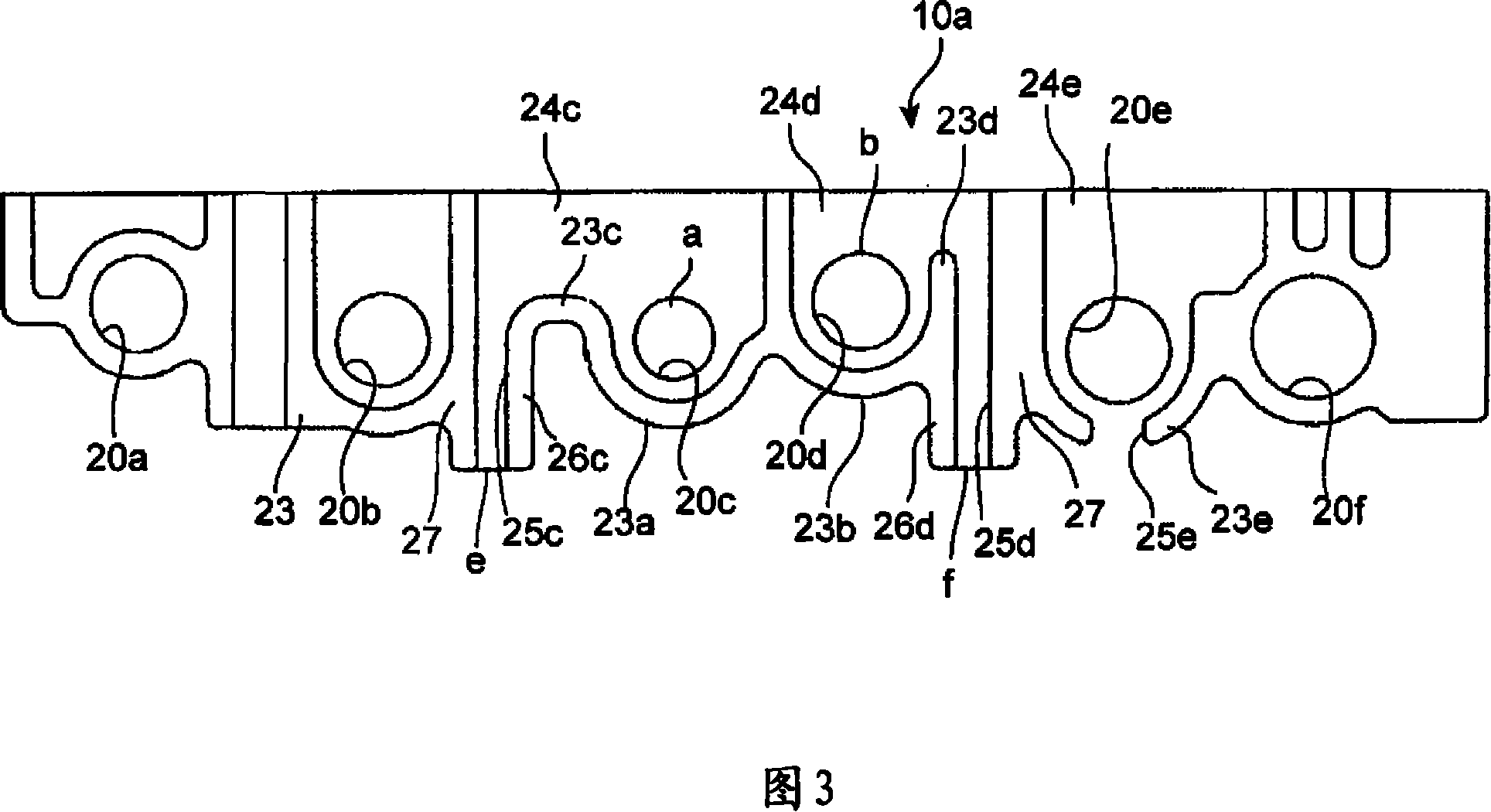

The invention discloses a variable-input three-dimensional spatial motion vibrating screen mechanism, which comprises a screen frame (8), a rack (0), a flat surface six-bar mechanism and a spatial branched chain, and is characterized in that six constructional elements of the flat surface six-bar mechanism, namely a constructional element 1 to a constructional element 6, are connected by a revolute pair 1 to a revolute pair 6 of which the axes are parallel in sequence; the constructional element 6 is taken as the rack (0); the constructional element 3 opposite to the rack (0) and the screen frame (8) are connected through a revolute pair 7 (R7) of which the axis is parallel to the axis of the constructional element 3; one end of the constructional element 7 (6) of the spatial branched chain is connected with the screen frame (8) by a ball pair 1 (S1); the other end of the constructional element 7 of the spatial branched chain is connected with one end of a constructional element 8 (7) through a ball pair 2 (S2); the other end of the constructional element 8 (7) is connected with the rack (0) through a revolute pair 8 (R8); three constructional elements connected with the rack (0) are drive rods; and when the movement of the three drive rods on the rack is controlled, the screen frame (8) can acquire one horizontal movement and two rotational outputs. The variable input three-dimensional spatial motion vibrating screen mechanism is simpler in structure and is easy to manufacture and process.

Owner:CHANGZHOU UNIV

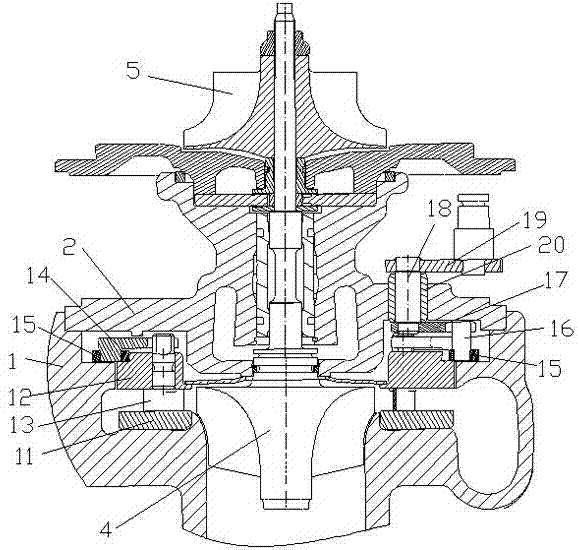

Sliding nozzle

InactiveCN103527264AAvoid precision lossHigh control precisionInternal combustion piston enginesStatorsThermal deformationEngineering

The invention discloses a sliding nozzle. A rotatable synchronous ring is arranged on an upper nozzle ring in a coaxial mode, and a synchronous ring inner circle connected with the upper nozzle ring in an assembling mode is of an interrupted structure in the radial direction. A first sliding block device comprises a flow guiding vane and an open shifting fork connected with the shaft end of the flow guiding vane. The shaft end of the flow guiding vane is provided with two parallel lateral planes. One end of the open shifting fork is connected with the two lateral planes in a matched mode. A second sliding block device comprises a main shifting fork assembly, one end of the main shifting fork assembly is connected with an actuator, and the other end of the main shifting fork assembly is connected with the synchronous ring through a synchronous pin. By means of the sliding nozzle, precision loss caused by fast abrasion of a line-plane friction pair in actual use is effectively avoided. Transmission precision and abrasion resistance are effectively improved. The inner circle is of an interrupted synchronous ring structure, matching area of the synchronous ring and the upper nozzle ring is reduced, and the phenomenon that the synchronous ring and the nozzle ring are clamped due to thermal deformation is effectively prevented.

Owner:汉美综合科技(常州)有限公司

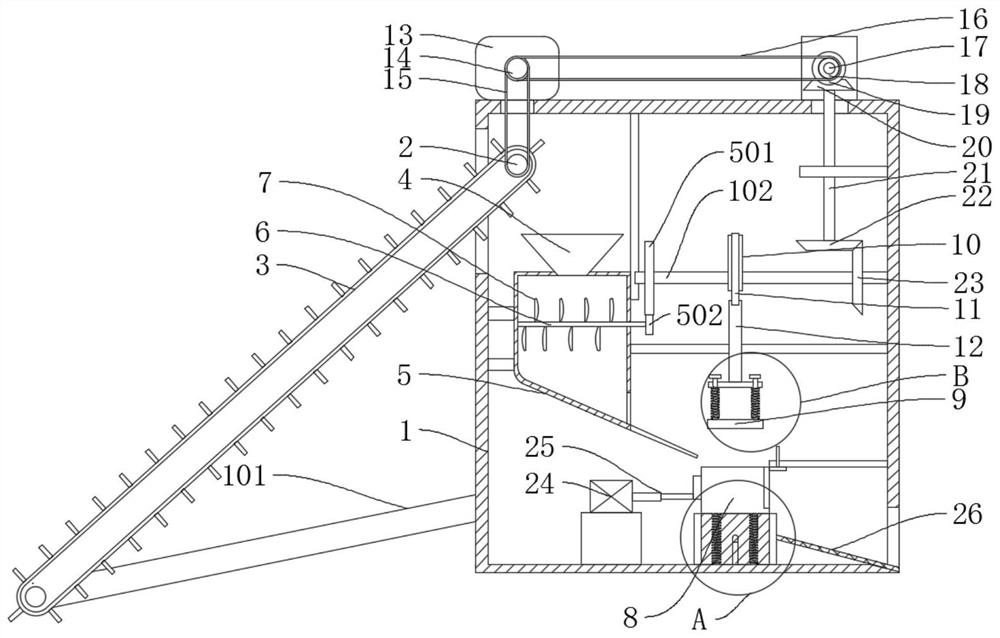

Anti-blocking muddy water type shield tunneling machine stirring device

The invention discloses an anti-blocking muddy water type shield tunneling machine stirring device. The anti-blocking muddy water type shield tunneling machine stirring device comprises a cutter headand a first stirring paddle. A shell is arranged at the rear of the cutter head, and an earth bin is arranged at the inner side of the shell. A sealing ring is arranged at the rear of the earth bin, and a pressure-bearing partition plate is arranged at the rear of the sealing ring. A feeding pipe is arranged above the pressure-bearing partition plate, and a threaded rod is arranged on the inner side of a discharging pipe. The first stirring paddle is located in front of the pressure-bearing partition plate, and a second stirring paddle is arranged at the rear of the first stirring paddle. A third stirring paddle is arranged at the rear of the second stirring paddle. A self-aligning roller bearing is arranged at the rear of a transmission rod, and a reducer is arranged at the rear of a coupling. According to the anti-blocking muddy water type shield tunneling machine stirring device, the second stirring paddle can be matched with the third stirring paddle during the use of the device, the mud crushed by the first stirring paddle can be stirred for many times, so that the soil can be stirred more finely and not prone to congealed.

Owner:GUIZHOU UNIV

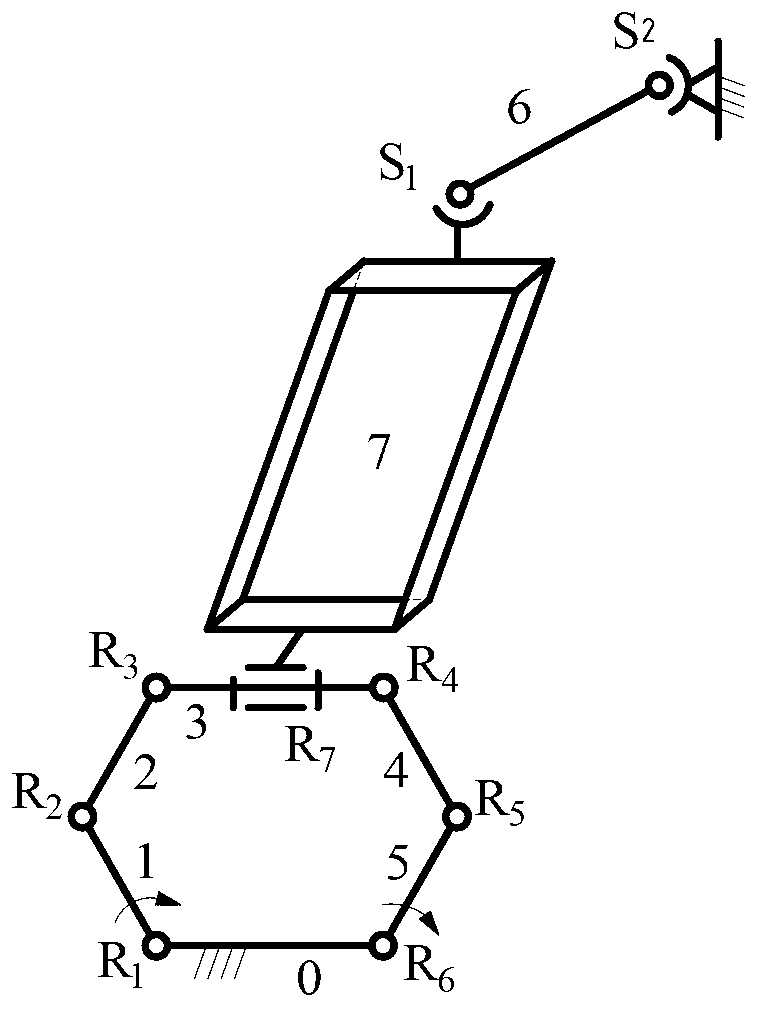

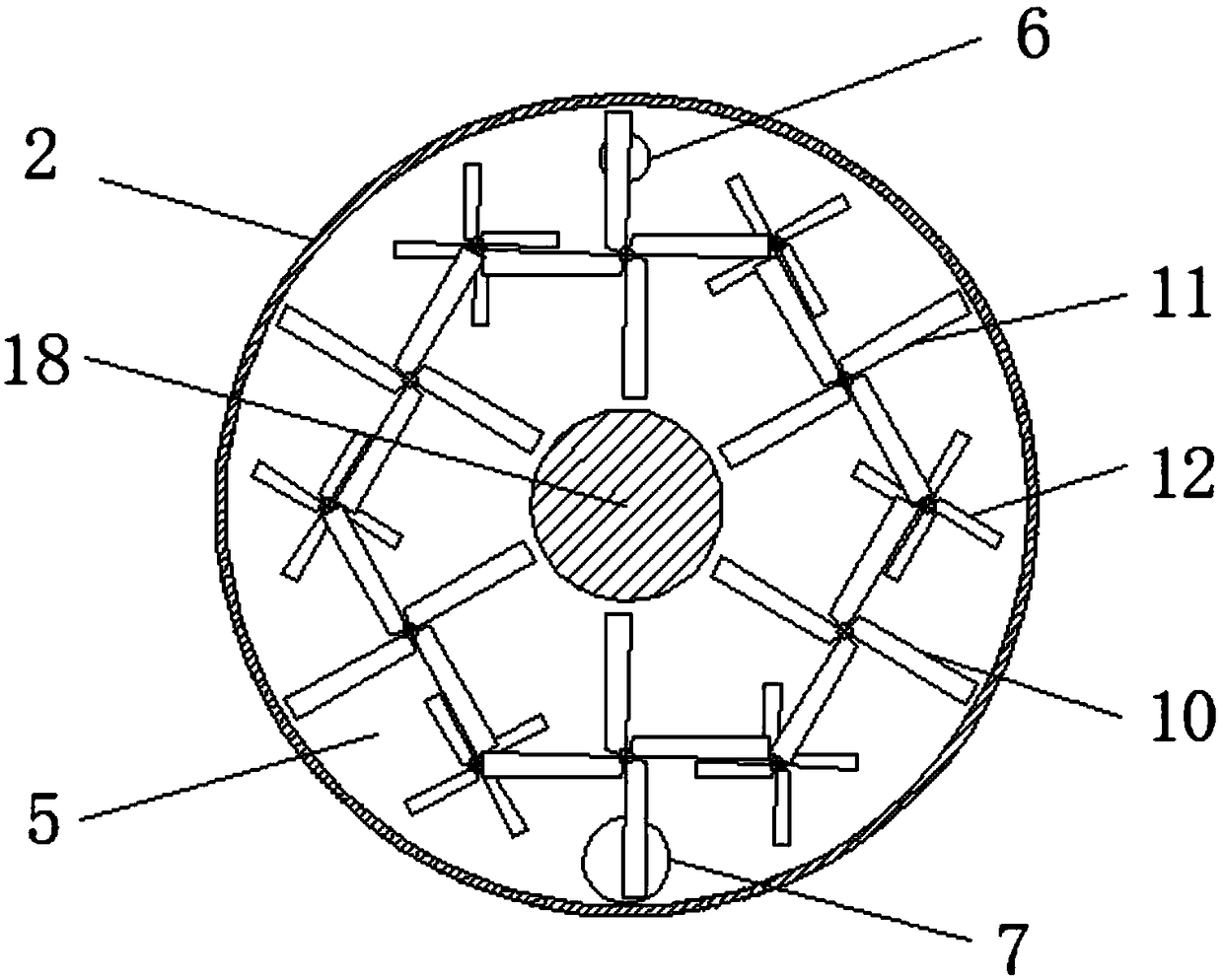

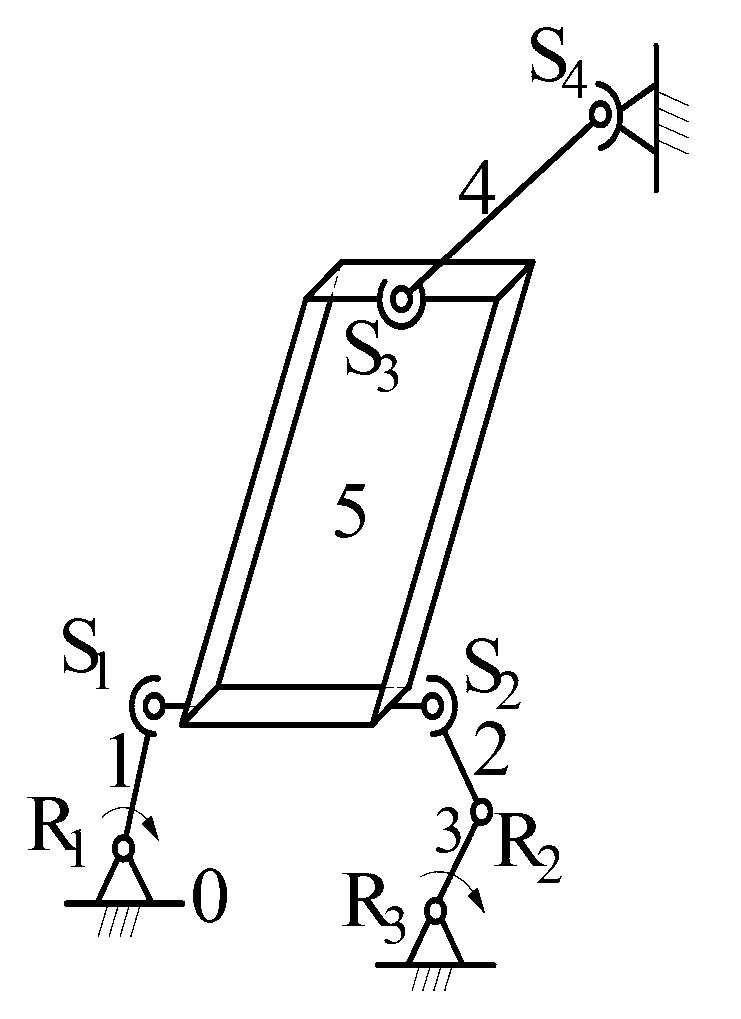

Variable input three-dimensional vibrating screen mechanism with analyzing forward position kinematic

InactiveCN103028544AImprove productivityImprove rigiditySievingScreeningEngineeringMechanical engineering

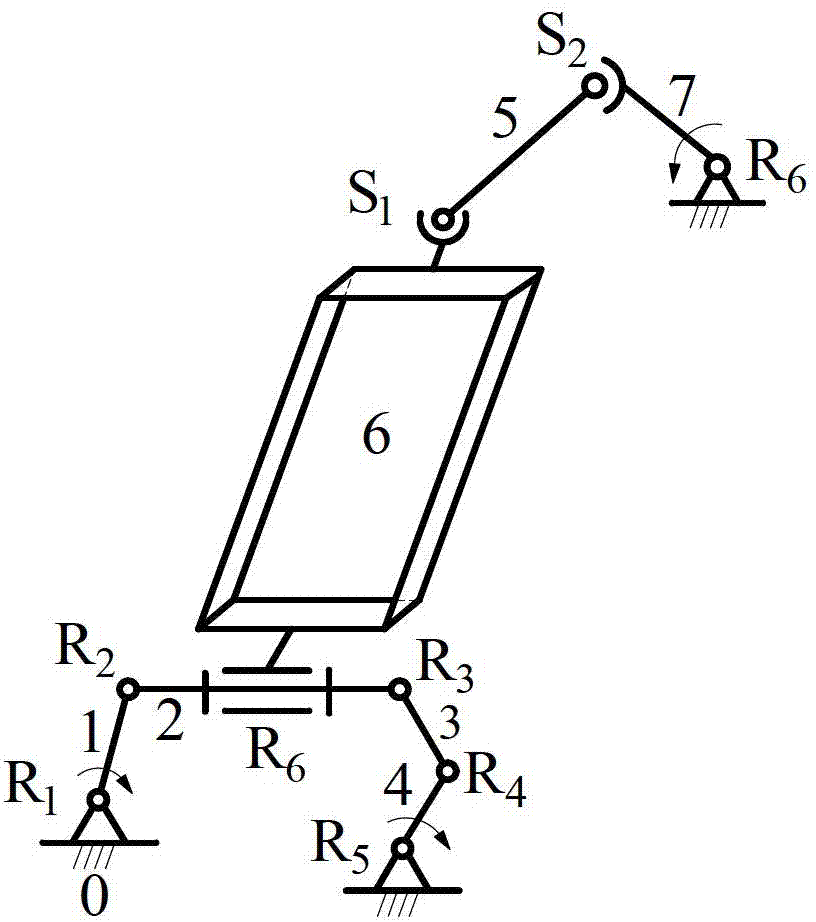

The invention relates to a variable input three-dimensional vibrating screen mechanism with analyzing forward position kinematic. The mechanism comprises a screen frame (6), a frame (0), a planar five-rod mechanism, and a space branch chain. The mechanism is characterized in that five members of the planar five-rod mechanism: the frame (0), a member I (1), a member II (2), a member III (3) and a member IV (4) are sequentially connected respectively through a rotary pair I (R1), a rotary pair II (R2), a rotary pair III (R3), a rotary pair IV (R4) and a rotary pair V (R5) with parallel axis. The member II (2) is connected with the screen frame (6) through a rotary pair VI (R6) with the axis parallel to the member II (2). One end of the member V (5) in the space branch chain is connected with the screen frame (6) by a ball pair I (S1) while the other end is connected with one end of the member V (7) through a ball pair II (S2). The other end of the member V (7) is connected with the frame (0) through the rotary pair VI (6). When three driving rods on the frame are controlled to move, the screen frame can obtain a translational and two rotatable moveable outputs. The mechanism is simpler in structure, has an analyzing forward position kinematic solution, and is easy to manufacture and process.

Owner:CHANGZHOU UNIV

Hydraulic circuit device and hybrid drive system using that hydraulic circuit device

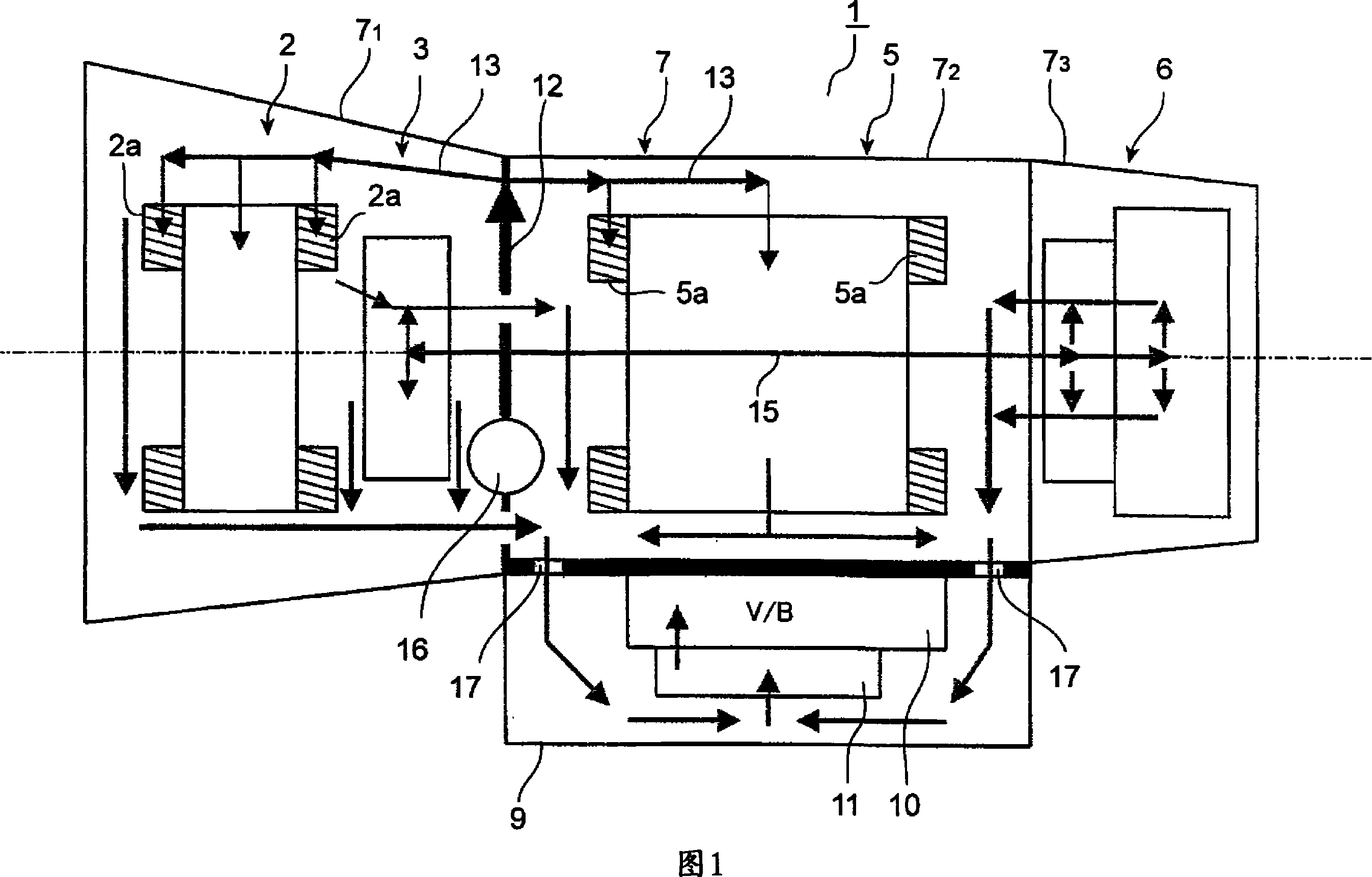

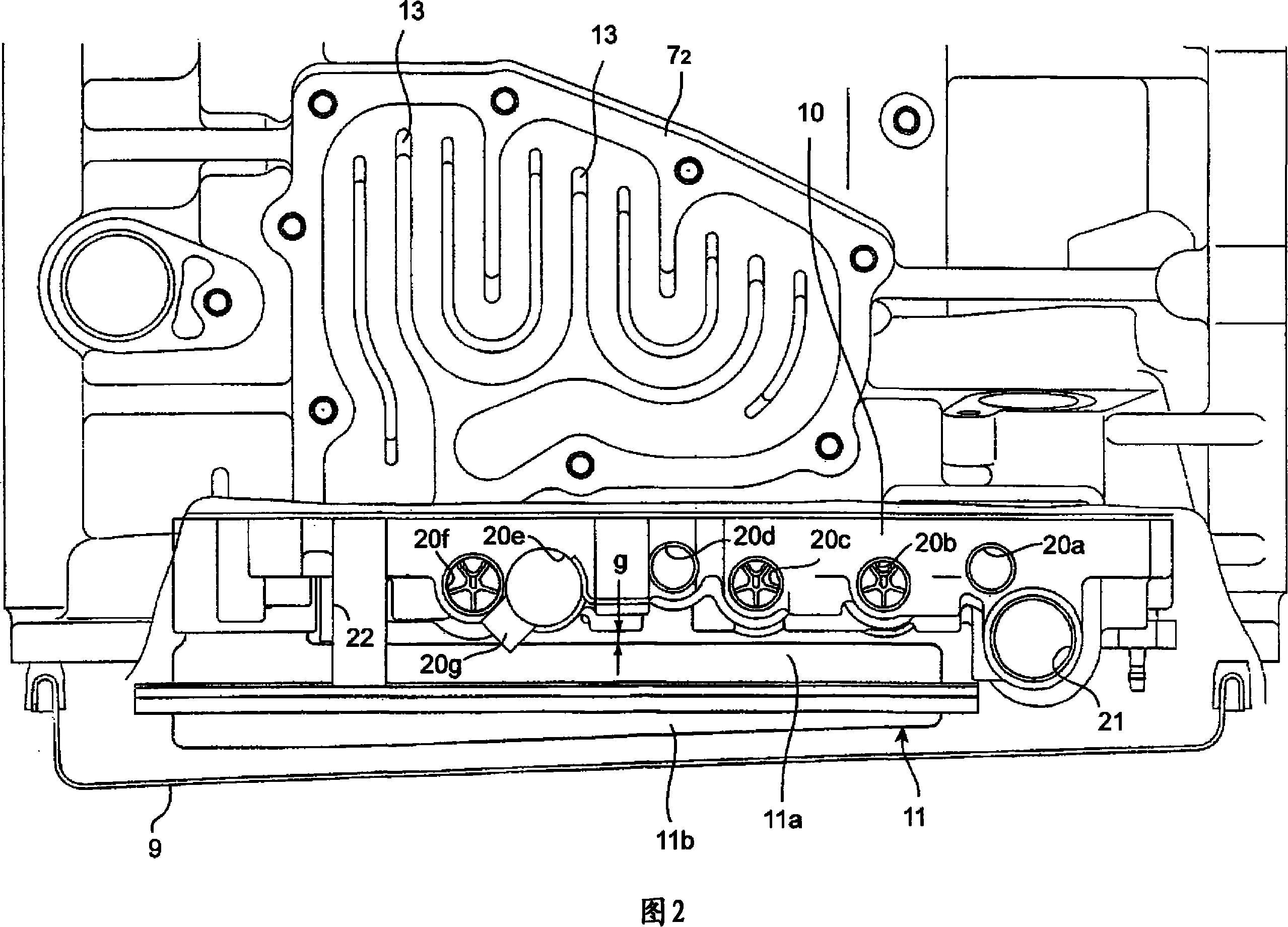

InactiveCN101128689AReduce the possibility of intrusionEasy dischargeHybrid vehiclesGas pressure propulsion mountingElectric machineHydraulic circuit

Drain holes are arranged in positions offset from valve holes of a valve body. The drain holes have a long chimney-shaped space such that even if insulation material, that has peeled off of an electric motor, is suspended in oil, it is less likely to enter drain chambers through the drain holes.

Owner:AISIN AW CO LTD +1

Grill

InactiveUS20120204731A1Good for healthMinimizing carbonizationRoasters/grillsBread-toastersGlass fiberManufacturing cost reduction

The present invention relates to a grill where a grilled object hardly sticks to the grill in case meat, fish, and the like are grilled thereon. The present invention implements a novel form of a grill wherein a grill has a function of simply putting the object to be grilled on a heat source and a function such as heat conduction or heat storage is minimized by using a metal wire having a small diameter of 0.1-2.0 mm, a nonflammable fireproof fiber such as carbon or glass fiber, and the like, thereby providing a grill which is sanitary because the grilled object hardly sticks or burns thereon and the taste of the grilled object is improved as much as possible. The grill provided by the present invention can improve health by minimizing carbonization in case of grilling, can reduce the number of grills, the cost of labor, detergent and cleaning water, can maximize the taste of direct grilled objects, and can reduce manufacturing costs.

Owner:YU YOUNG WHAN

Axle system

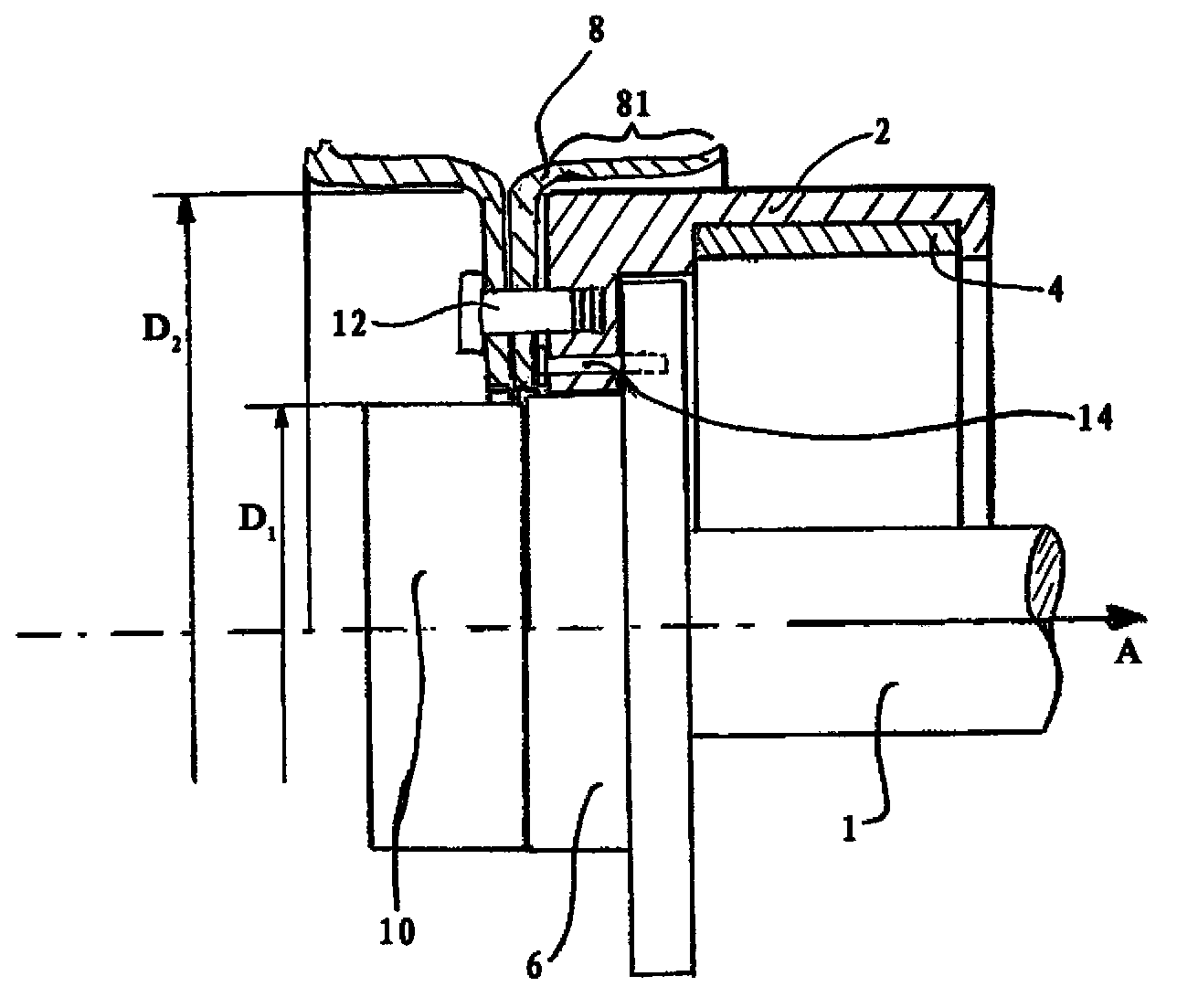

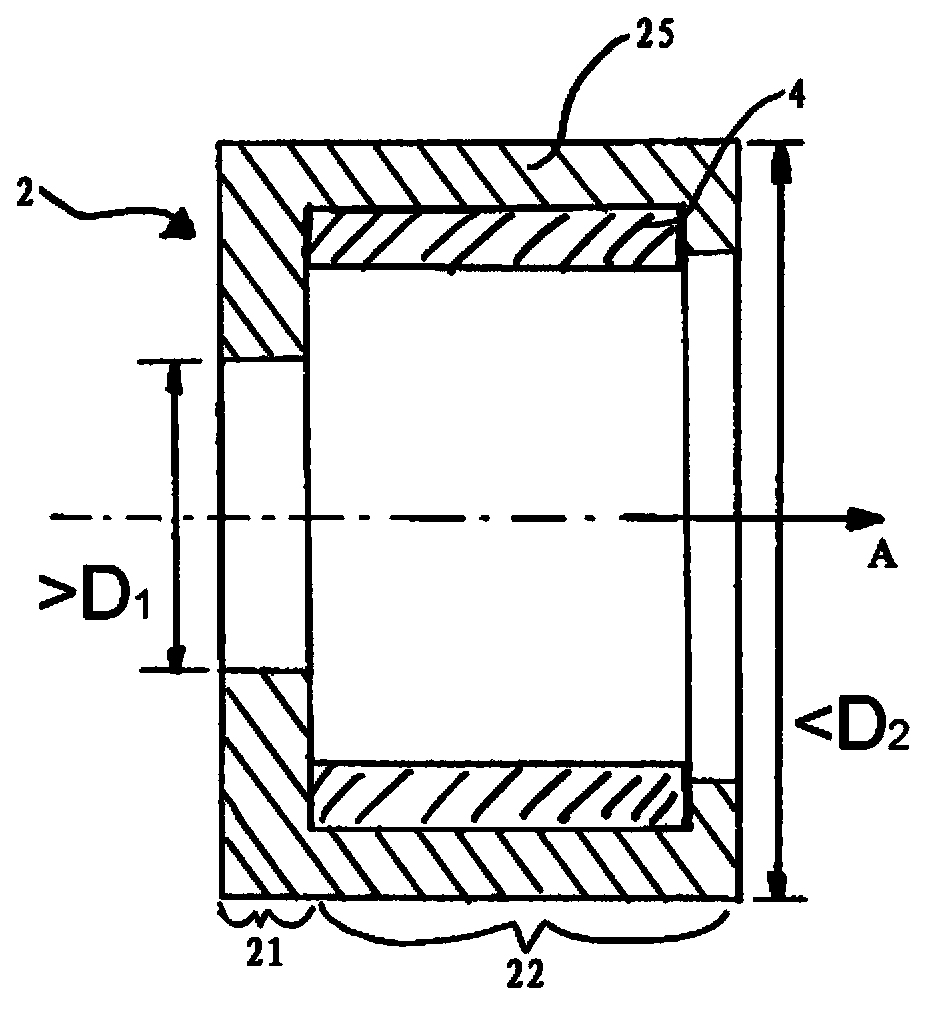

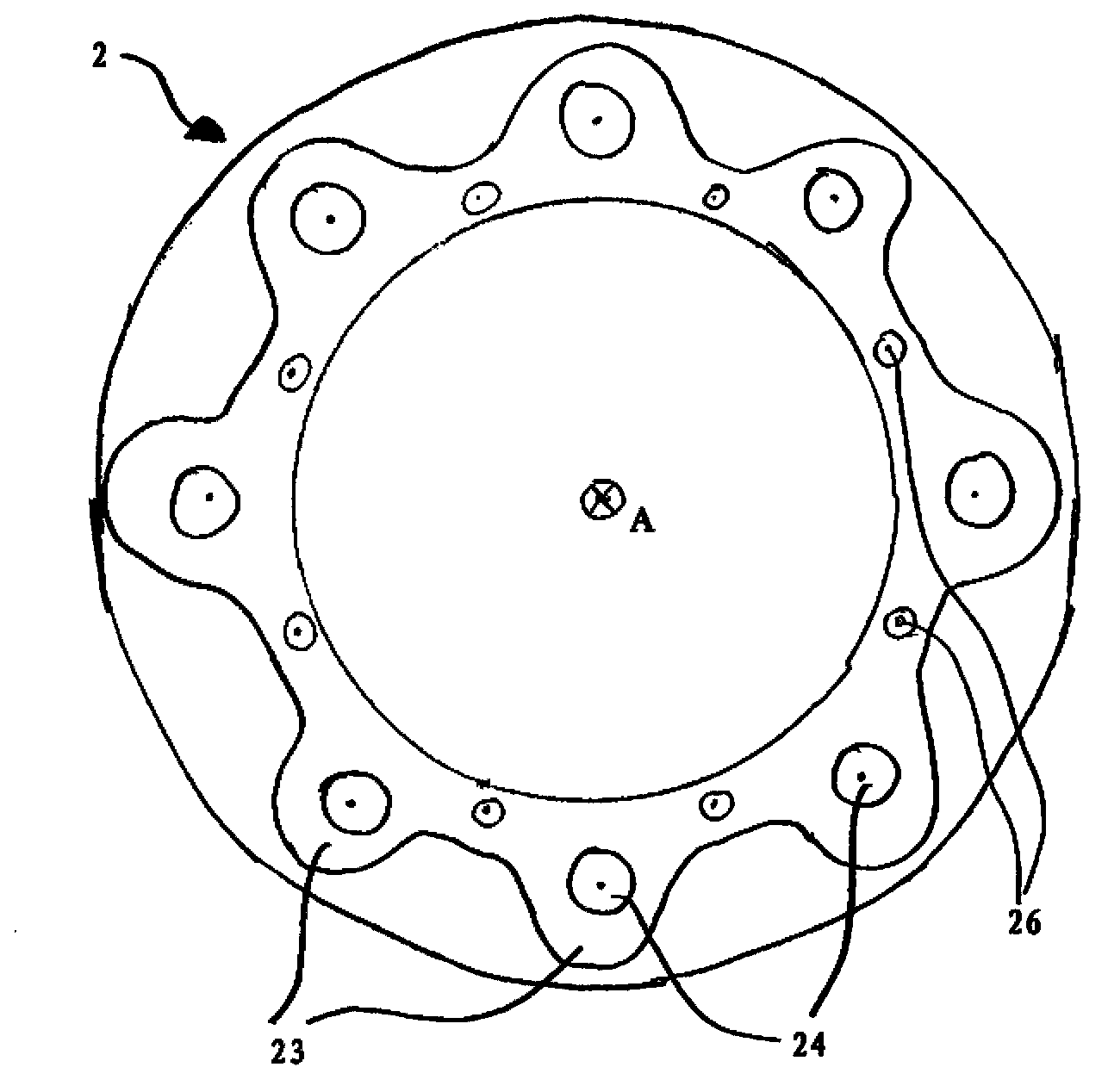

ActiveCN103889734AHigh strengthAddress material needsHubsVehicle sub-unit featuresEngineeringInternal dimension

Axle system, in particular axle system for utility vehicles, comprising an external unit, a hub unit and a brake drum element, wherein the external unit has a maximum extent D1 transversely with respect to an axis of rotation, wherein the brake drum element comprises a face part, which extends transversely with respect to the axis of rotation and has a cutout, and a drum casing, which extends substantially parallel to the axis of rotation, wherein the cutout of the face part has an extent transversely with respect to the axis of rotation of at least D1, wherein the extent of the drum casing transversely with respect to the axis of rotation is smaller than the internal dimension D2 of an attachment unit which can be fixed to and at least partially surrounds the brake drum element, wherein the external unit is arranged in the direction of the axis of rotation on the hub unit, and wherein the brake drum element can be moved over the external unit and fixed to the hub unit.

Owner:SAF HOLLAND GMBH

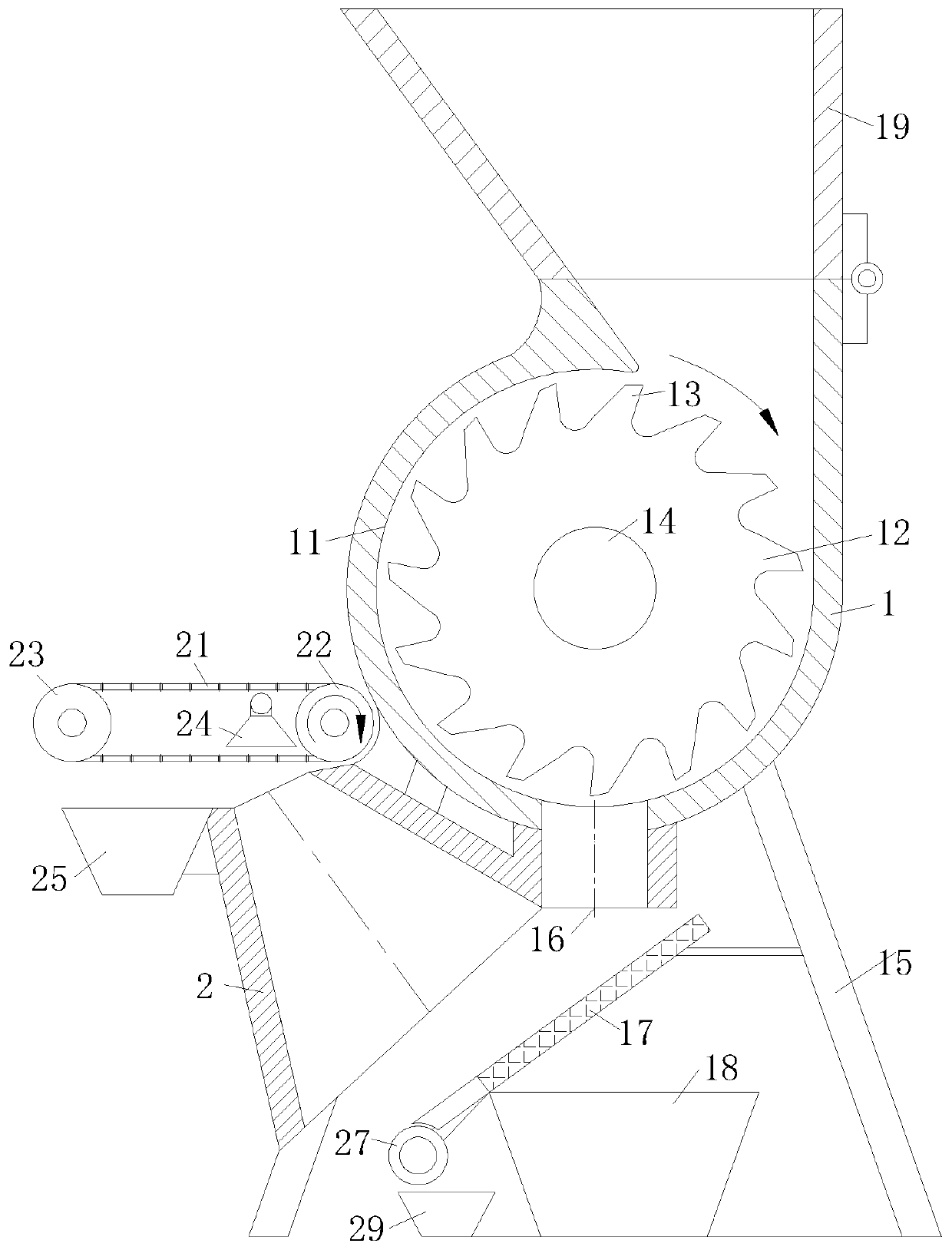

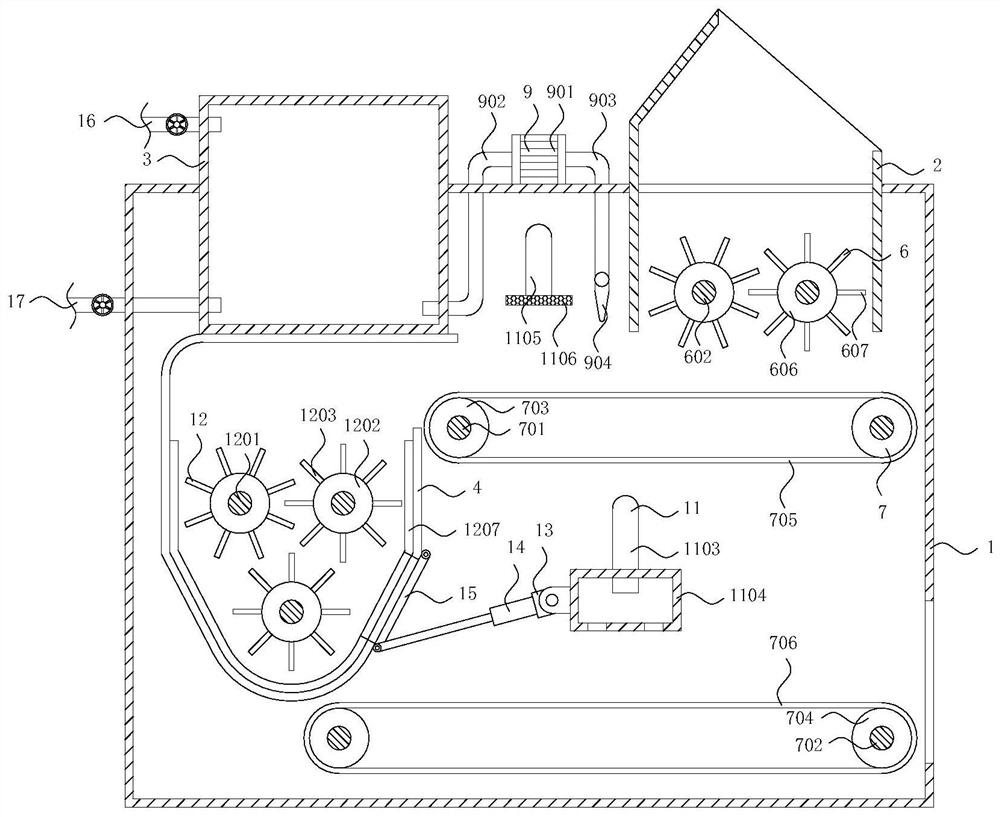

Crusher for construction waste

ActiveCN110898939AQuick breakImprove crushing efficiencyGas current separationGrain treatmentsArchitectural engineeringStructural engineering

The invention belongs to the technical field of construction waste treatment, and particularly relates to a crusher for construction waste. The crusher comprises a machine shell, wherein a crushing cavity is formed in the machine shell, and a crushing wheel is rotationally connected in the crushing cavity; a supporting rod is arranged at the bottom of the machine shell, a discharging hole is formed in the bottom of the crushing cavity, an inclined screen is arranged below the discharging hole, and the screen is fixedly connected with the supporting rod through a support; the lower portion of the screen is provided with a first hopper for collecting concrete particles, a feeding hopper is hinged to the upper portion of the machine shell, the height of the crusher is reduced after the feeding hopper is turned over, the transportation is convenient, the feeding hopper is large at the upper portion and is small at the lower portion, and the side wall on one side of the feeding hopper is vertically arranged and is tangent to the crushing cavity. According to the crusher, the side wall at one side of the feeding hopper is vertically arranged and is tangent to the crushing cavity, so thatwood garbage with the larger length is tightly attached to the side wall tangent to the feeding hopper and the crushing cavity when the wood garbage is crushed, the beating of wood materials is reduced, meanwhile, the condition that the wood materials are clamped into the feeding hopper is reduced, and therefore, the crushing efficiency of the wood materials is increased.

Owner:上海筱启新能源科技集团有限公司

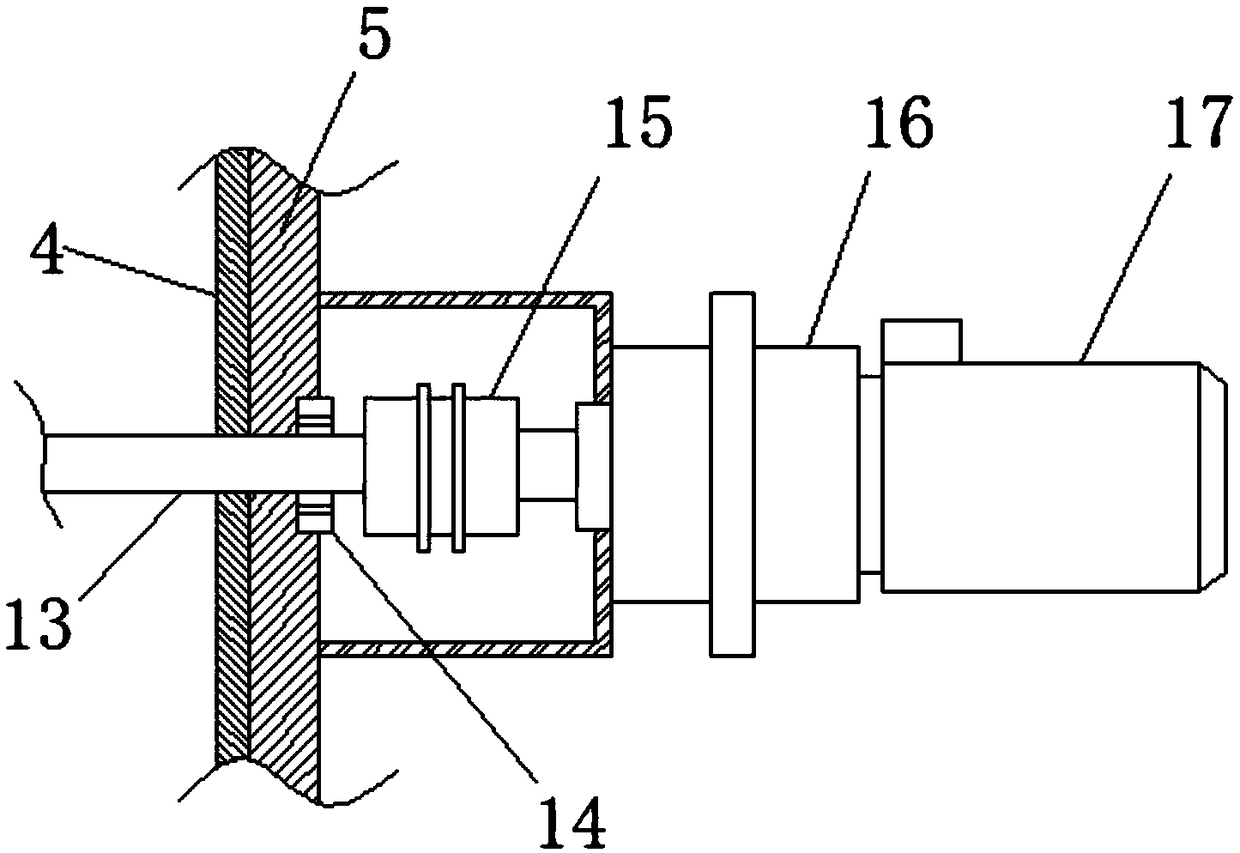

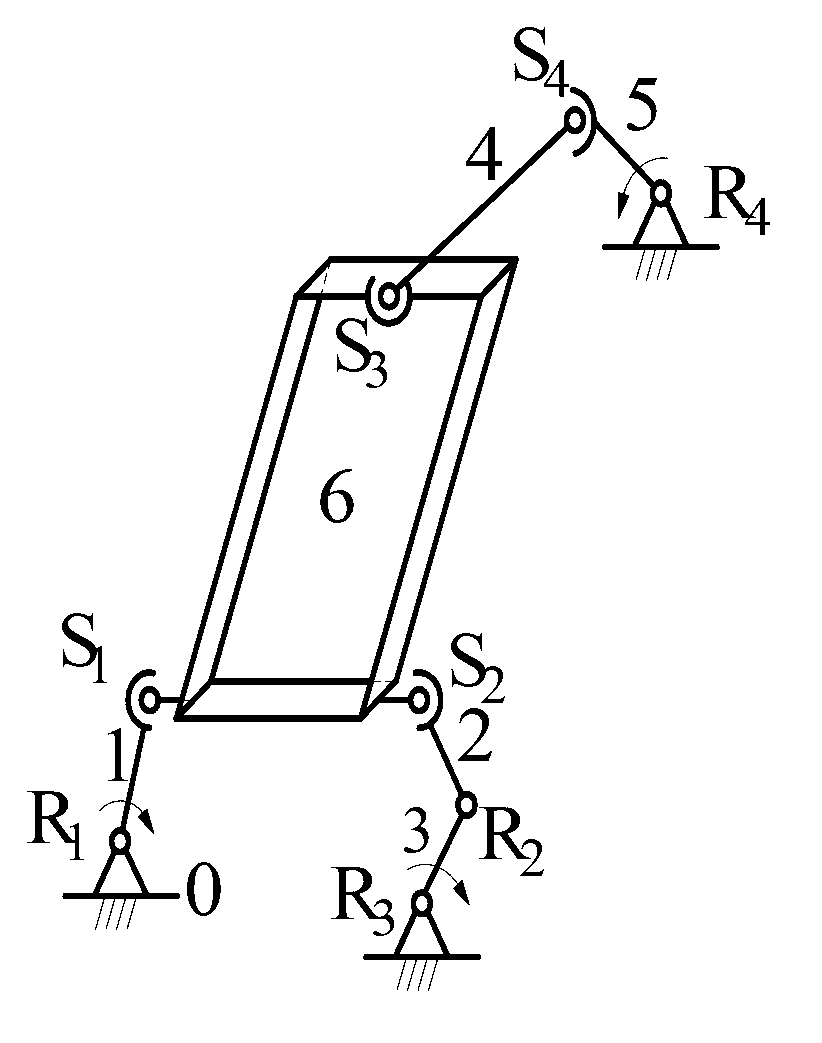

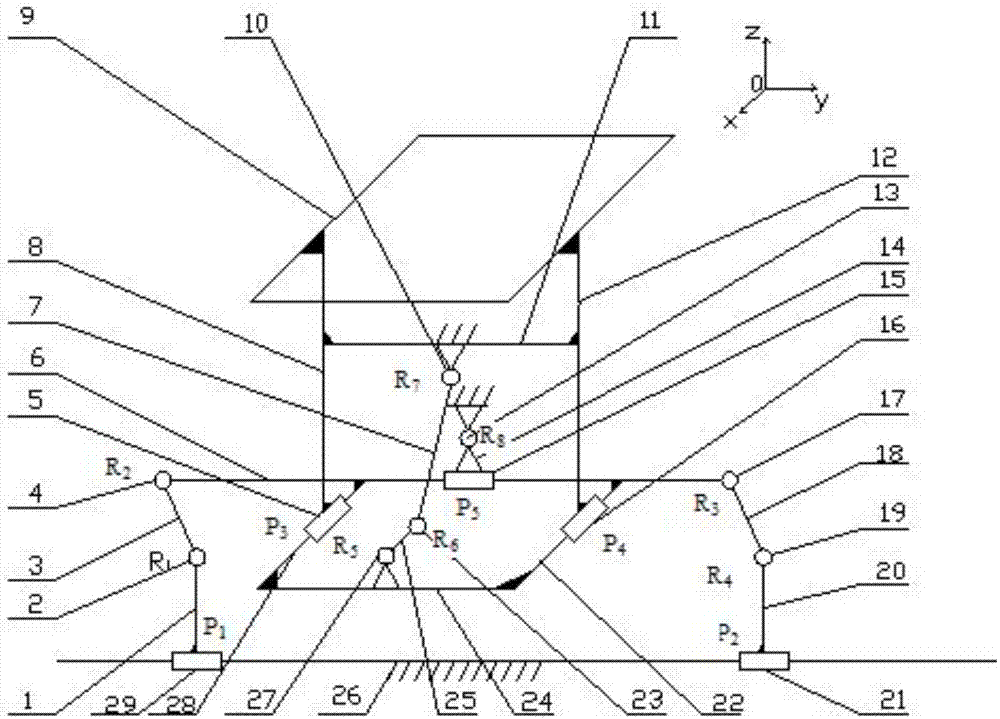

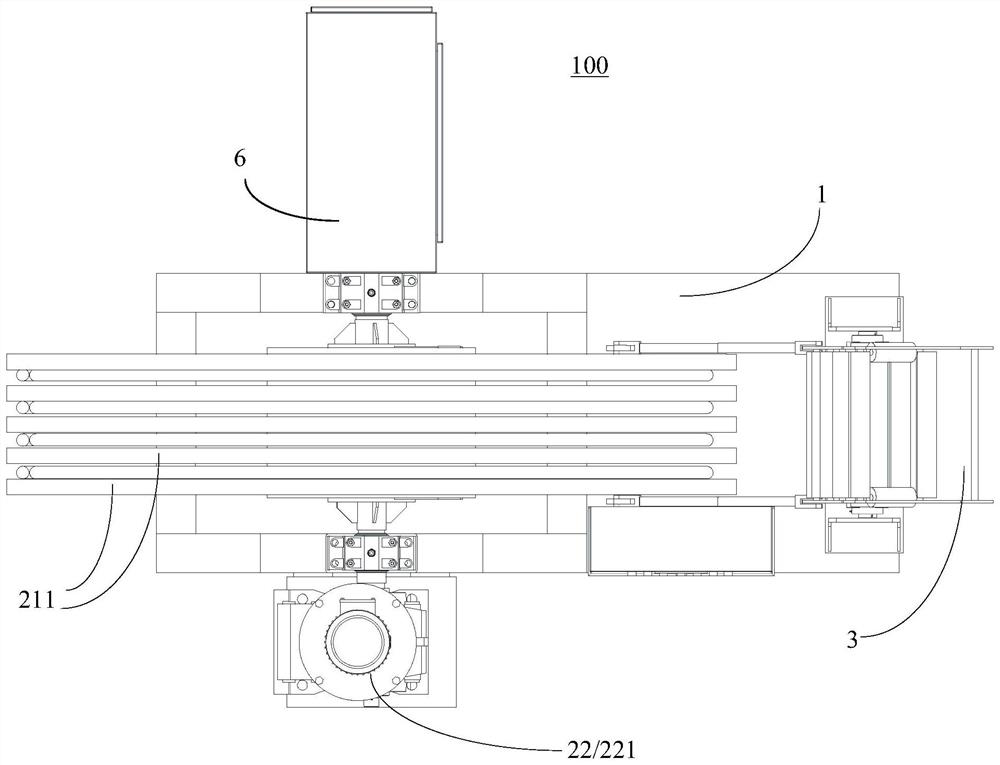

Three-dimensional motion device for analyzing positive solution of position and partially decoupling control

InactiveCN102990646AImprove rigidityImprove dynamic performanceProgramme-controlled manipulatorClassical mechanicsKinematic pair

The invention discloses a three-dimensional motion device for analyzing a positive solution of a position and partially decoupling control. The three-dimensional motion device comprises a platform (6), a frame (0), a first branched chain, a second branched chain and a third branched chain. The three-dimensional motion device is characterized in that one end of a member 1(1) of the first branched chain is connected with the platform (6) by a spherical joint 1(S1); the other end is connected to the frame (0) by a revolute pair 1(R1); one end of a member 2(2) of the second branched chain is connected to the platform (6) by a spherical joint 2(S2); the other end is connected to one end of a member 3(3) by a revolute pair 2(R2) while the other end of the member 3(3) is connected to the frame (0) by a revolute pair 3(R3); one end of a member (4) of the third branched chain is connected to the platform (6) by a spherical joint 3(S3); the other end is connected to one end of a member 5(5) by a revolute pair 4(S4) while the other end of the member 5(5) is connected to the frame (0) by a revolute pair 4(R4); the axes of the revolute pair 1, the revolute pair 2 and the revolute pair 3 are parallel to each other; the spherical joint 1(S1), the spherical joint 2(S2) and the spherical joint 3(S3) on the platform (6) are not on the same straight line; and three members connected to the frame (0) are drive rods. The platform can obtain an independent translation and two independent rotation outputs when movement of three single-freedom kinematic pairs on the frame is controlled. Therefore, the mechanism is simple in structure, and easy to manufacture and process, and controls decoupling.

Owner:CHANGZHOU UNIV

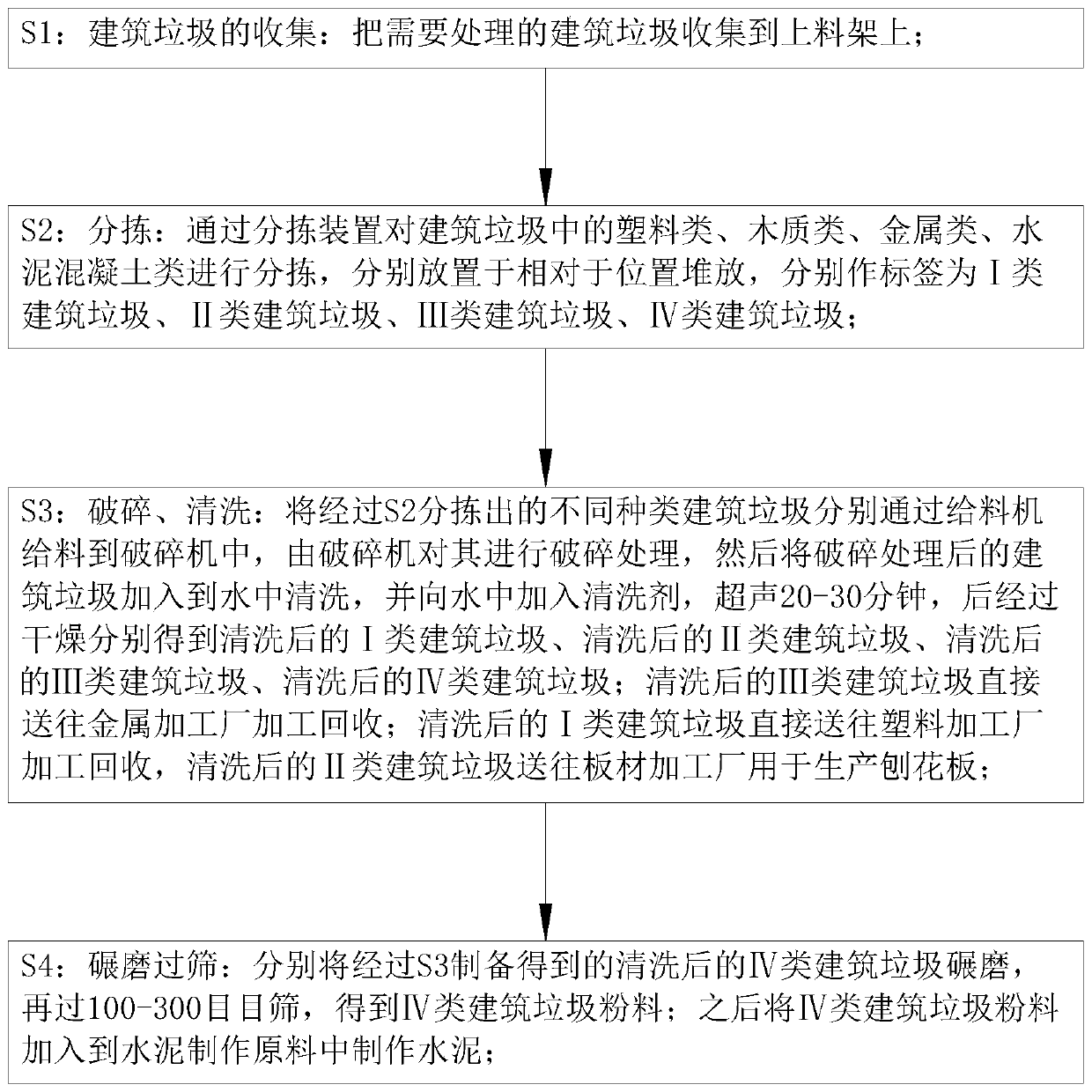

Construction waste classification and recovery method

ActiveCN110899301AQuick breakEasy to clean up and take awayConstruction waste recoveryGas current separationAgricultural engineeringWaste treatment

The invention belongs to the technical field of waste treatment, and particularly relates to a construction waste classification and recovery method. According to the recovery method, an involved crusher used for crushing wood construction waste comprises a machine shell, a crushing cavity is formed in the machine shell, a crushing wheel is rotationally connected in the crushing cavity, a supporting rod is arranged at the bottom of the machine shell, a material discharging hole is formed in the bottom of the crushing cavity, an inclined screen is arranged below the material discharging hole, the screen is fixedly connected with the supporting rod through a support, the lower portion of the screen is provided with a first bucket for collecting concrete particles, a feeding hopper is hingedto the upper portion of the machine shell, after the feeding hopper is turned over, the height of the crusher is reduced so as to facilitate transport, the upper part of the feeding hopper is large while the lower part of the feeding hopper is small, and a side wall of one side of the feeding hopper is vertically arranged and tangent to the crushing cavity. According to the method, the side wall of the one side of the feeding hopper is vertically arranged and tangent to the crushing cavity, wood waste with large length is enabled to be tightly attached to the side wall, tangent to the crushingcavity, of the feeding hopper when being crushed, the bounce of the wood is reduced, meanwhile, the situation that the feeding hopper is jammed by the wood is reduced, and then the crushing efficiency of the wood is increased.

Owner:烟台腾泰环保建材有限公司

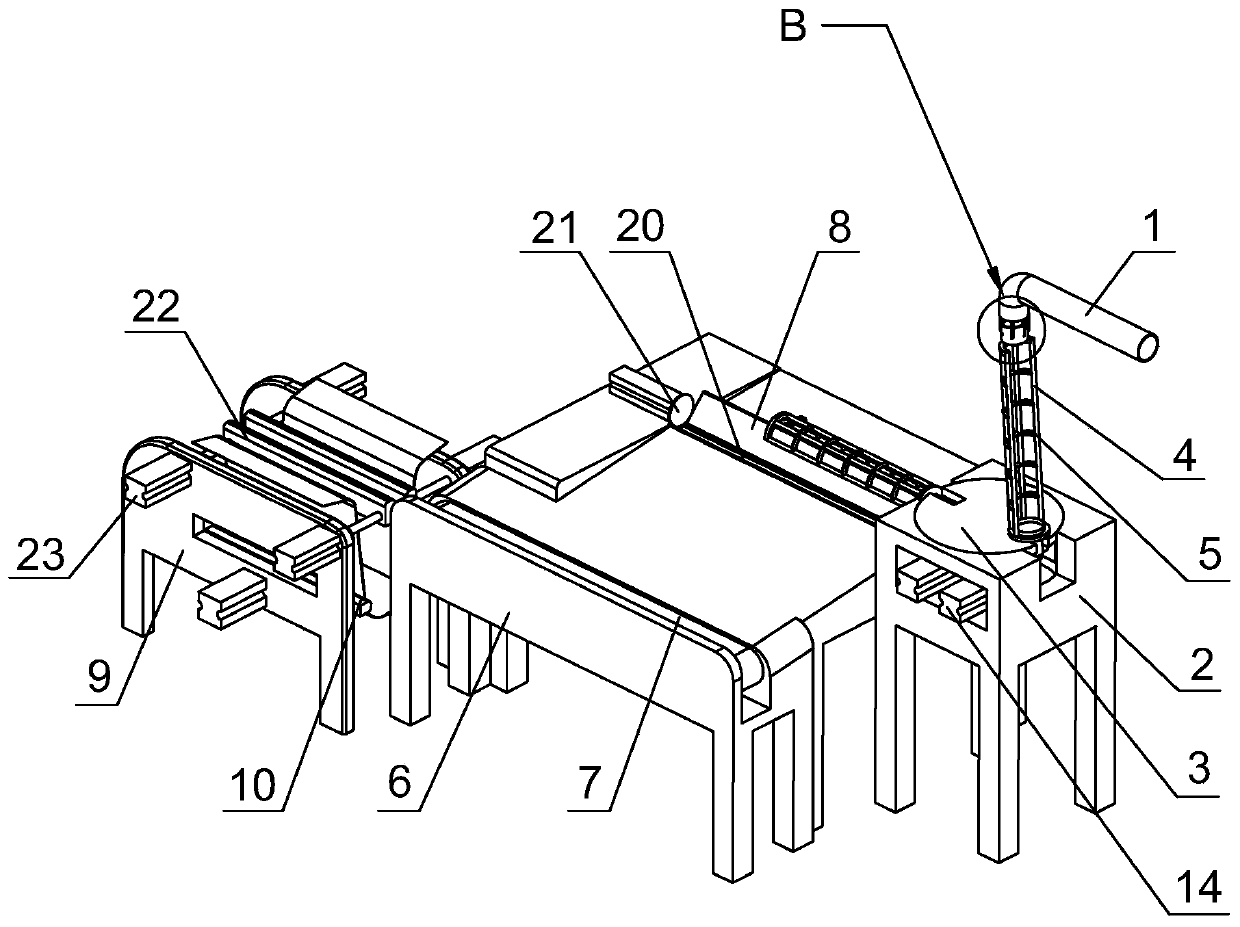

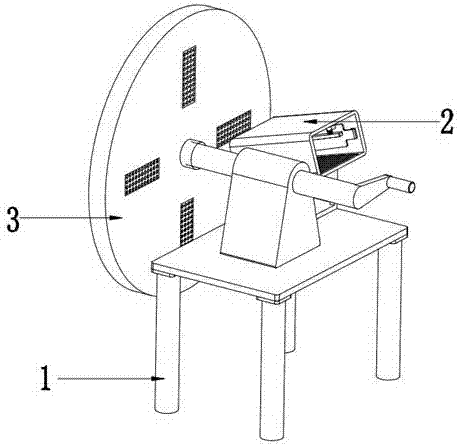

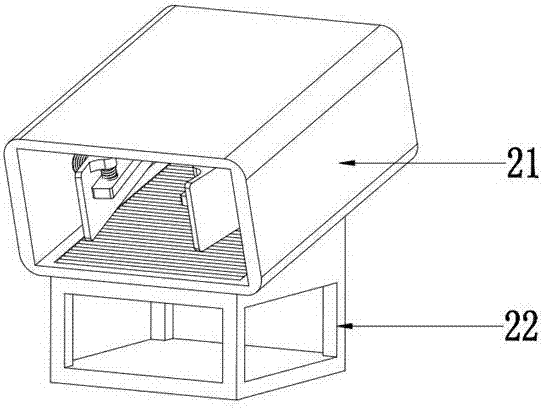

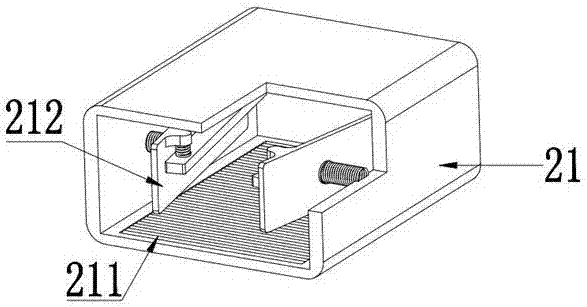

Paper cup online collecting and automatic packaging device

ActiveCN110422380ALess stuckEfficient transfer processWrapper twisting/gatheringIndividual articlesTransfer mechanismPaper cup

The invention discloses a paper cup online collecting and automatic packaging device, and relates to the technical field of paper cup automatic production equipment. The paper cup online collecting and automatic packaging device solves the problems that a sliding groove is difficult to adjust and the function is limited due to the fact that a paper cup with higher height cannot be met, the paper cup online collecting and automatic packaging device comprises a glass guide pipe, a rack, a sorting mechanism, a transferring mechanism and a bagging mechanism, wherein the glass guide pipe is used for outputting paper cup finished products, the sorting mechanism comprises a sorting turntable and two cup collecting cages, wherein the sorting turntable is rotationally arranged on the rack, and a guide outlet is formed in one side, away from each other, of the two cup collecting cages. The paper cup finished products in the cup collecting cage are directly transferred from the cup collecting cage to the placing table, so that the paper cup finished products with different stacking heights can be transferred, the situation that the paper cup finished products are clamped in the cup collectingcage is effectively reduced, the paper cup finished products with different stacking heights can be rapidly packaged, the function is more complete, and the production efficiency is higher.

Owner:武汉丽诺工贸有限公司

Sweet potato shredding machine

The invention discloses a sweet potato shredding machine. The sweet potato shredding machine comprises a base, a guide chute and a rotary table cutter, wherein a rectangular support plate is arranged on the upper surface of the base, four backing plates are arranged on the lower surfaces of four corners of the support plate, and columns are connected to the lower parts of the backing plates; the guide chute is installed in the surface of the base and is divided into a support seat and a guide port which is installed in the support seat; and the rotary table cutter is composed of a rotating shaft support seat, a handlebar, a rotating shaft, a rotary table and a shredding cutter, the rotating shaft is connected with the handlebar and is installed on the rotating shaft support seat, the rotary table is installed on one end of the rotating shaft, and the shredding cutter is installed on the rotary table. The sweet potato shredding machine has the advantages of simple structure and scientific and reasonable design, the problems of low efficiency, high labor intensity and hurt to hands due to manual shredding of sweet potatoes in traditional rural families are solved, and the problem of jamming of the sweet potatoes which are shredded by a sweet potato shredding machine on the present market is also solved.

Owner:GUIGANG HOUSHUN INFORMATION TECH CO LTD

Wrench polishing equipment for hardware

The invention discloses wrench polishing equipment for hardware. The wrench polishing equipment structurally comprises a supporting frame, a polishing table, a polisher and a controller, the polishing table is horizontally welded to the top of the supporting frame, the polisher is installed at the top of the polishing table, the controller is arranged in the middle of the front face of the polishing table, due to the fact that chippings easily enter along a gap between a threaded groove of the polishing table and a push rod, the chippings are blocked through a telescopic pipe of a blocking mechanism, the situation that the chippings enters the gap between the threaded groove of the polishing table and the push rod can be reduced, the phenomenon that the push rod is clamped when being in threaded fit with the threaded groove is reduced, free lifting of a supporting plate is facilitated, a wrench is normally driven to be matched with the polisher for polishing treatment, part of chippings are easily retained on the inner wall, close to the outer end, of an exhaust port, contact blocks make contact with the inner wall of the exhaust port, the chippings on the inner wall of the exhaust port are removed through a removing plate, resistance of the chippings to a clamping plate can be reduced, and the back-and-forth moving speed of the clamping plate in the exhaust port is increased.

Owner:上海曰茶贸易有限公司

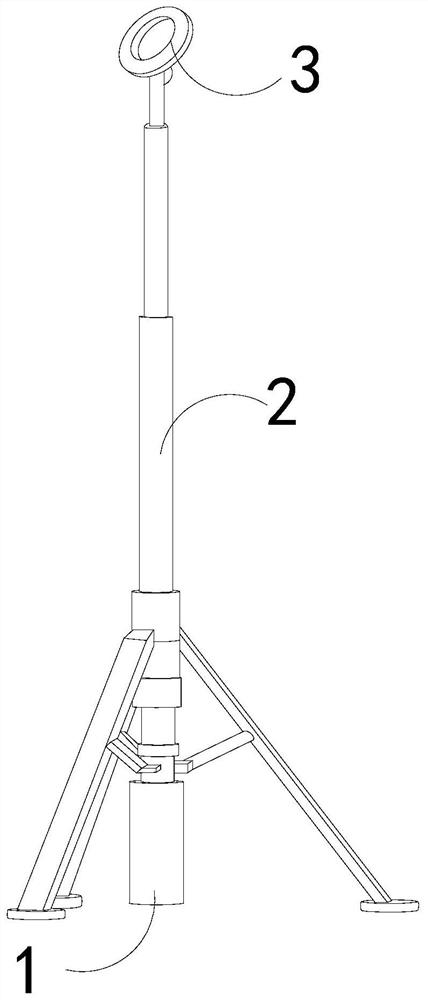

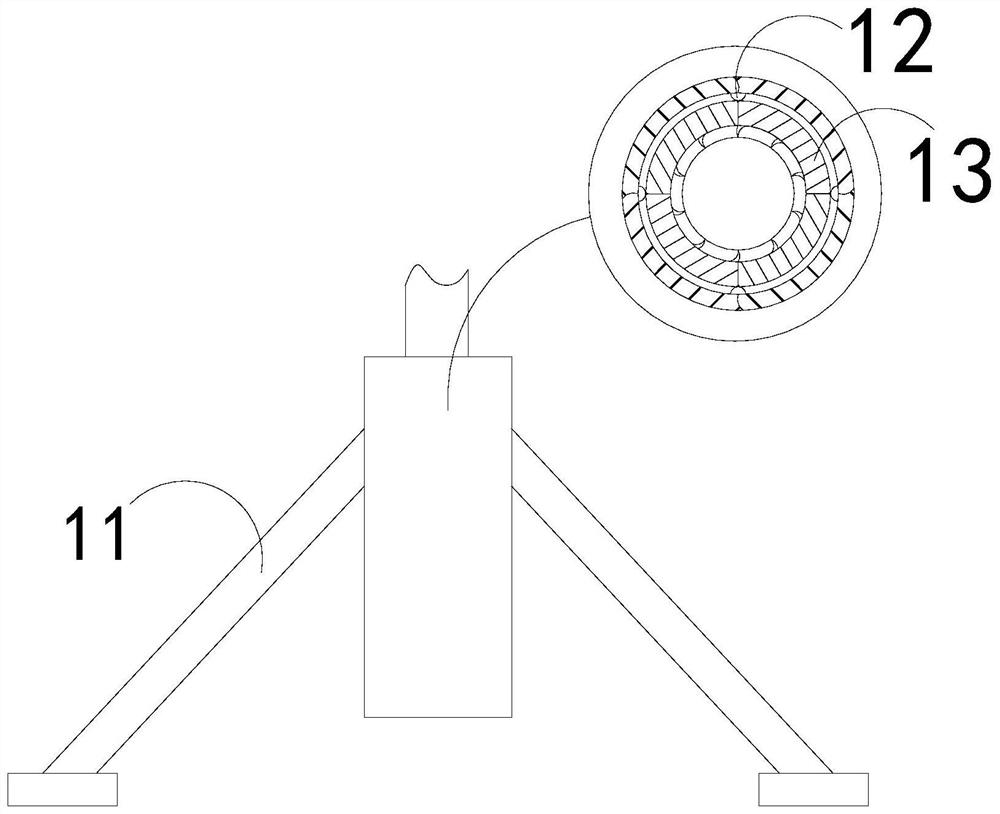

Outdoor support with high wind resistance and for 5G antenna installation

InactiveCN112310599AReduce accumulationLess stuckAntenna supports/mountingsDe-icing/drying-out arrangements5GStructural engineering

The invention discloses an outdoor support with high wind resistance and for 5G antenna installation. The outdoor support structurally comprises a base, a telescopic rod and an antenna clamp, whereinthe telescopic rod is movably matched with the interior of the top end of the base. Due to the fact that a protective paint layer on the outer wall of the telescopic rod falls off after long-term friction, the protective paint layer is clamped between threads and is gradually compacted, so the telescopic rod is clamped in the telescopic process; the protective paint layer on the outer wall of thetelescopic rod is removed through a brush plate of a removing mechanism, so accumulation of the protective paint layer in threads on the outer wall of the telescopic rod is reduced, jamming of the base and the telescopic rod in the telescopic process is reduced, the height of the 5G antenna is normally changed, and 5G signal receiving and transmitting of the antenna are enhanced; rainwater easilyenters the base along a gap between the base and the telescopic rod in rainy days, and internal gas is diffused to the base through deformation of a heat dissipation device, so the speed air flowing in the base is increased, water evaporation in the base is accelerated, rusting of the outer wall of the telescopic rod is reduced, and a movable fitting speed of the telescopic rod and the base is increased.

Owner:陈俊翔

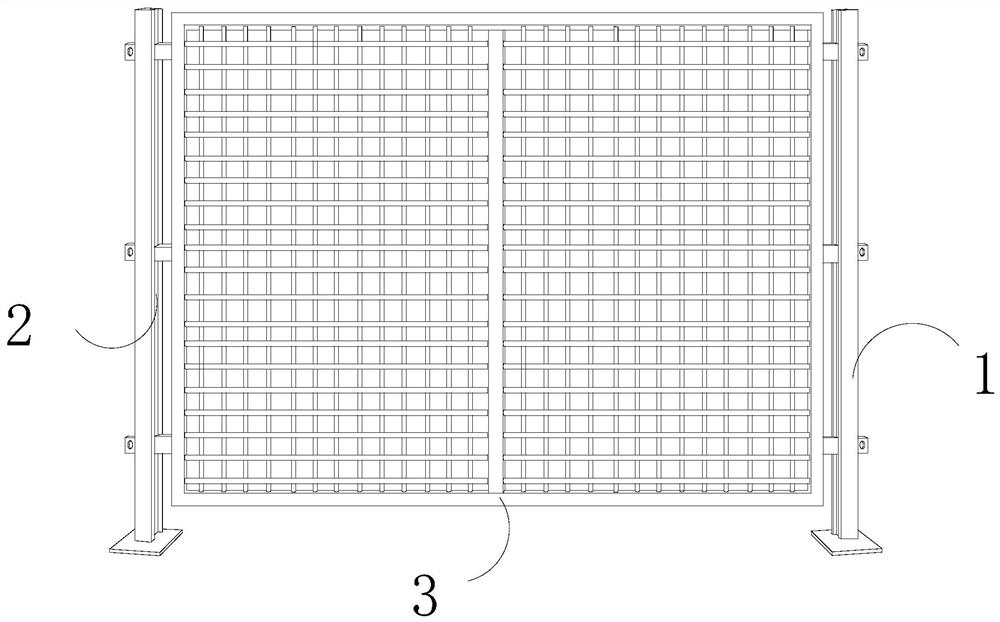

Anti-climbing protection equipment for electric power facilities

InactiveCN112554642ALess stuckReduce height variabilityDispersed particle filtrationTransportation and packagingControl theoryMechanical engineering

The invention discloses anti-climbing protection equipment for electric power facilities. The anti-climbing protection equipment structurally comprises a support rod, a sliding rail and an isolation net, wherein the sliding rail is sunken in the inner side of the support rod, the isolation net is movably matched with the support rod through the sliding rail, and the isolation net is provided witha bracket, net strips, a sliding block and pushing mechanisms. Dust in the sliding rail is gradually accumulated and is coagulated into blocks together with water molecules, the pushing mechanisms move up and down along with the isolation net, and the dust on the inner wall of the sliding rail is pushed and removed by pushing teeth, so that the matching degree of the sliding rail and the sliding block is increased, the phenomenon of different heights of both ends of the isolation net due to clamping of the isolation net in a sliding process is reduced, and the electric power facilities can benormally separated by the isolation net; and the dust easily enters an inner groove towards an exhaust hole when falling, a swing block in the exhaust hole swings along with airflow, and the swing block is tightly attached to the inner top of the exhaust hole, so that the dust is blocked, the condition that the dust enters the inner groove along the exhaust hole is reduced, and the airflow diffusion speed in the inner groove is increased.

Owner:唐山系罗商贸有限责任公司

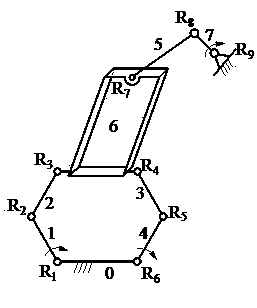

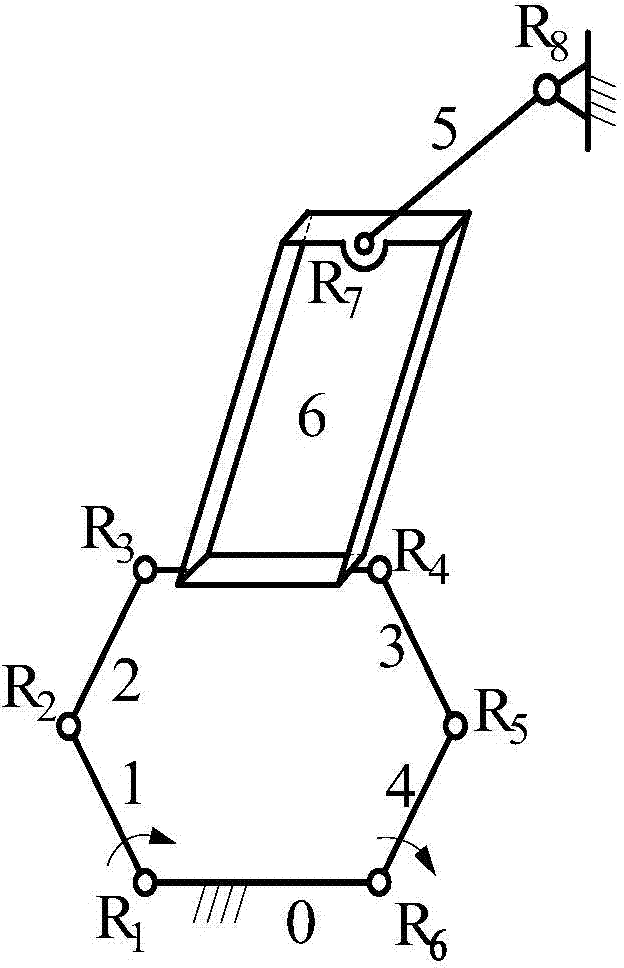

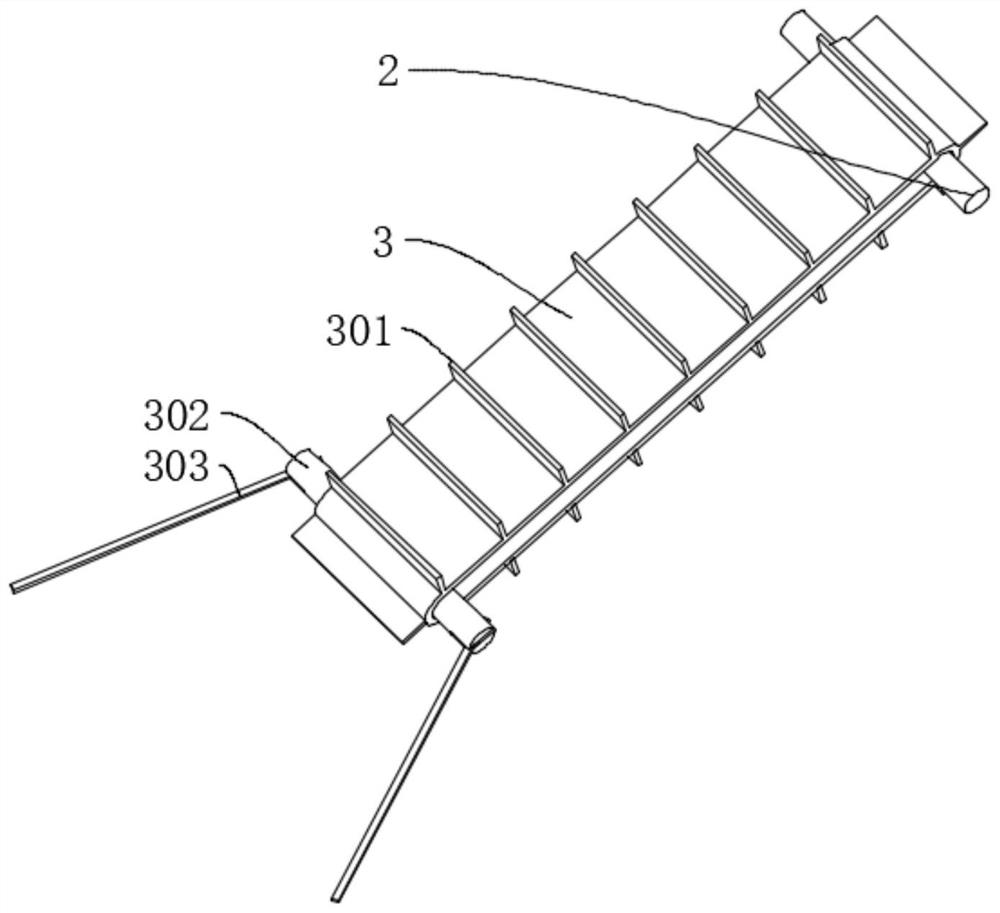

Three-dimensional moving vibrating screen mechanism

The invention relates to a three-dimensional moving vibrating screen mechanism which comprises a screen frame (6), a machine frame (0), and first, second and third branch chains, wherein one end of a second component (2) of the first branch chain is connected with the screen frame (6) through a third rotating pair (R3) while the other end is connected with one end of a first component (1) through a second rotating pair (R2); the other end of the first component (1) is connected with the machine frame (0) through a first rotating pair (R1); one end of a third component (3) of the second branch chain is connected with the screen frame (6) through a fourth rotating pair (R4) while the other end is connected with one end of a fourth component (4) through a fifth rotating pair (R5); the other end of the fourth component (4) is connected with the machine frame (0) through a sixth rotating pair (R6); one end of a fifth component (5) of the third branch chain is connected with the screen frame (6) through a seventh rotating pair (R7) while the other end is connected with one end of a sixth component (7) through an eighth rotating pair (R8): the other end of the sixth component (7) is connected with the machine frame (0) through a ninth rotating pair (R9). The three-dimensional moving vibrating screen mechanism is simple in structure and is easy to manufacture and process.

Owner:JIANGSU UNIV

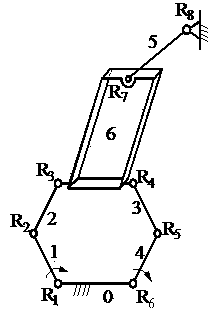

Plane type variable input and controllable 3D movement vibrating sieve mechanism

The invention provides a plane type variable input and controllable 3D movement vibrating sieve mechanism. The mechanism comprises a sieving frame (6), a rack (0), a first branch chain, a second branch chain and a third branch chain, wherein the three branch chains have the same structure. The mechanism is characterized in that one of the ends of parts (2, 3) of the first branch chain and the second branch chain is respectively connected with the sieve frame (6) through rotating pairs (R3, R4), and while the other one of the ends of parts (2, 3) of the first branch chain and the second branch chain is respectively connected with one of the ends of the parts (1, 4) through rotating pairs (R2, R5); the other one of the ends of the parts (1, 4) is respectively connected with the rack (0) through rotating pairs (R1, R6); one end of a part (5) of the third branch chain is connected with the sieve frame (6) through the rotating pair (R7) and while the other end of the part (5) is connected to one end of a part (7) through a rotating pair (R8); the other end of a part (7) is connected with the rack (0) through a rotating pair (R9); the axes of all rotating pairs are parallel; the rotating pairs (R3, R4, R7) are not in a straight line; driving rods (1, 4, 7) can be controlled to move, and then the sieve frame can gain two-translation and one-rotating type output.

Owner:CHANGZHOU UNIV

Remediation treatment device for treating contaminated soil through atomization and spraying of reagent

InactiveCN112317527AImprove governance efficiencyNo need for manual transportTransportation and packagingRotary stirring mixersSoil remediationEnvironmental engineering

The invention discloses a remediation treatment device for treating contaminated soil through atomization and spraying of a reagent, belonging to the technical field of soil remediation. The remediation treatment device comprises a device box, wherein a feeding box is fixedly mounted at the top of the device box, openings are formed in the top and the bottom of the feeding box, a stirring box is fixedly mounted on the inner wall of the device box, a chemical receiving box is fixedly mounted at the top of the stirring box, and the top of the chemical receiving box extends to the upper part of the device box. According to the remediation treatment device for treating the contaminated soil through atomization and spraying of the reagent, in virtue of cooperative use of an air suction machine,a purification machine, an air outlet pipe, an air collection box, an air suction pipe and a separation net, waste gas generated in a stirring mechanism is absorbed, absorption of harmful waste gas by animals and plants is reduced, the body health of people is guaranteed, heated and purified soil can be cooled, and influence of relatively hot purified soil on manual collection is reduced.

Owner:湖州桑农生态农业有限公司

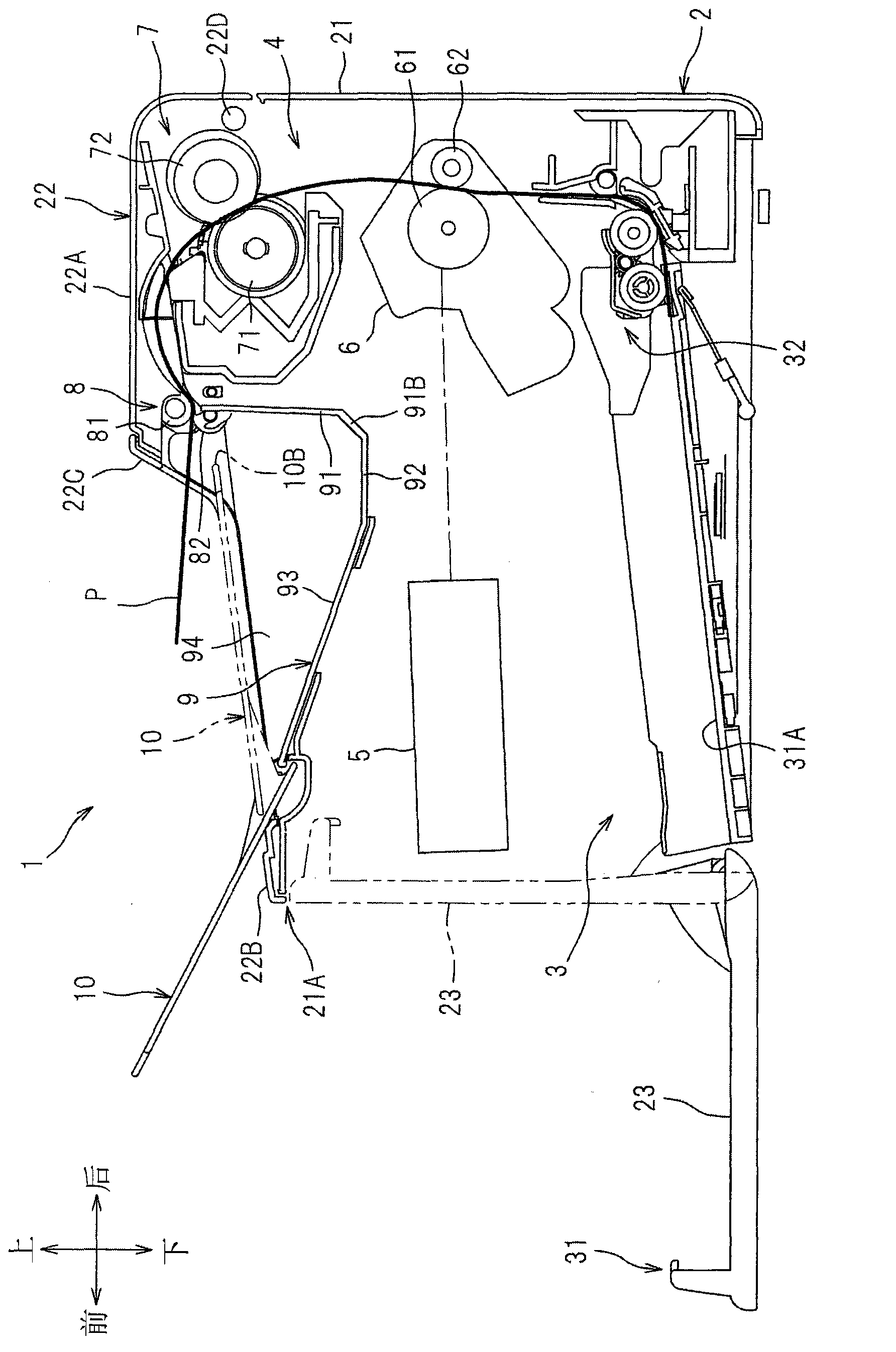

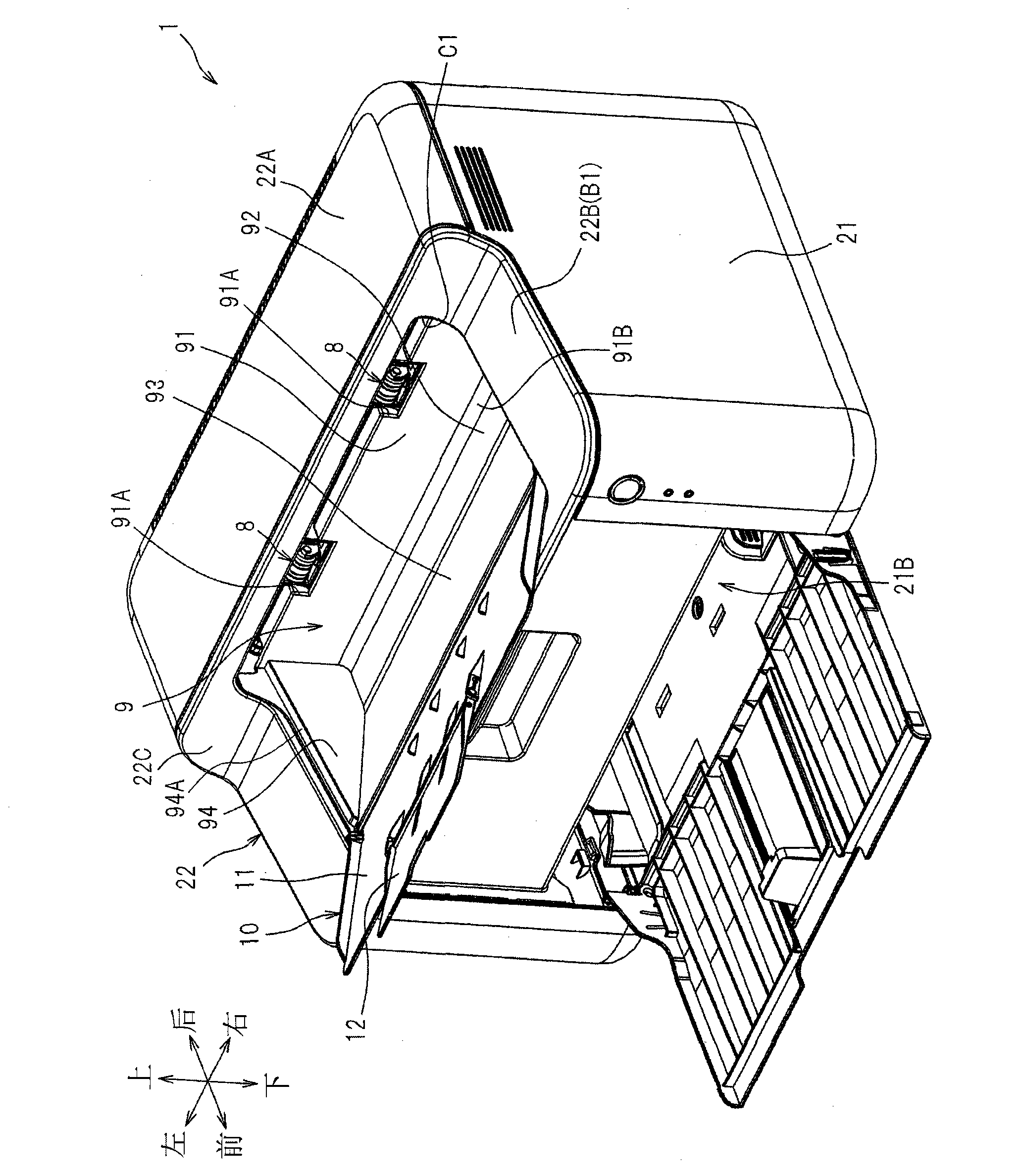

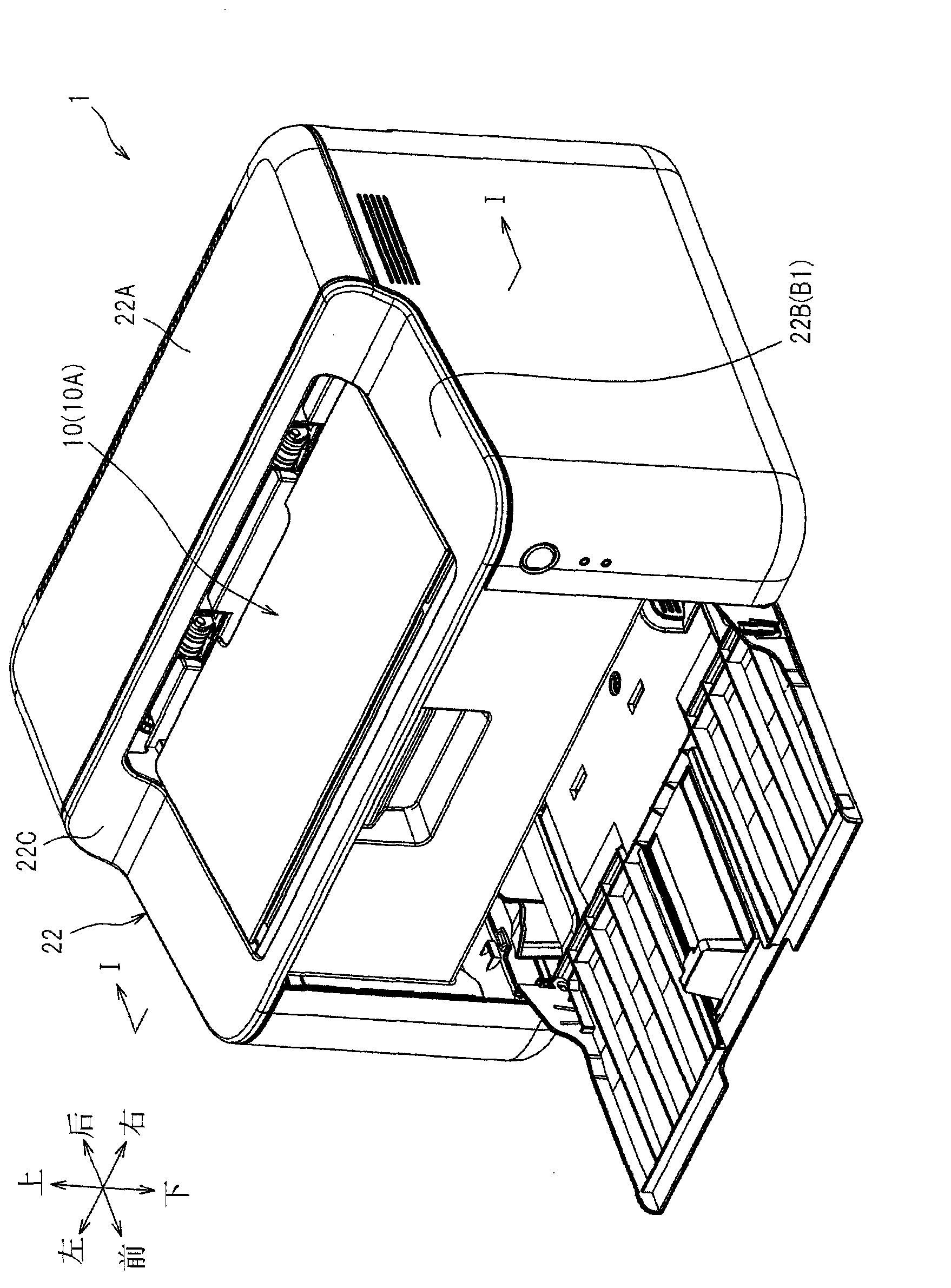

Image forming apparatus

ActiveCN103224158ALess stuckElectrographic process apparatusPile receiversImage formationEngineering

Owner:BROTHER KOGYO KK

Outdoor plant cultivation device

PendingCN112314287ATo achieve the covering effectSimple structurePlant protective coveringsAgricultural engineeringStructural engineering

The invention discloses an outdoor plant cultivation device which comprises two supporting assemblies, a sun-shading assembly and an adjusting assembly. Each supporting assembly comprises a supportingrod and a guide arm, and the top ends of the two guide arms are hinged to the tops of the two supporting rods correspondingly; the sun-shading assembly comprises a first connecting rod, a second connecting rod and a covering part, the two ends of the first connecting rod are connected to the tops of the two supporting rods respectively, the second connecting rod is connected between the two guidearms, the covering part is located between the two guide arms, one side edge of the covering part is fixedly connected to the first connecting rod, and the other side edge of the covering piece is connected with the second connecting rod; the adjusting assembly is arranged on at least one supporting assembly and used for adjusting the sliding position of a sliding table on the supporting rods, sothat the covering angle is adjusted, different terrains or weathers can be adaptively adjusted, the structure is simple, use of corresponding disassembling and assembling tools is not needed, and adjustment is convenient; and when the outdoor plant cultivation device needs to retract back, adjusting arms and the guide arms can retract back at the same time, and the aesthetics is improved.

Owner:FOSHAN UNIVERSITY

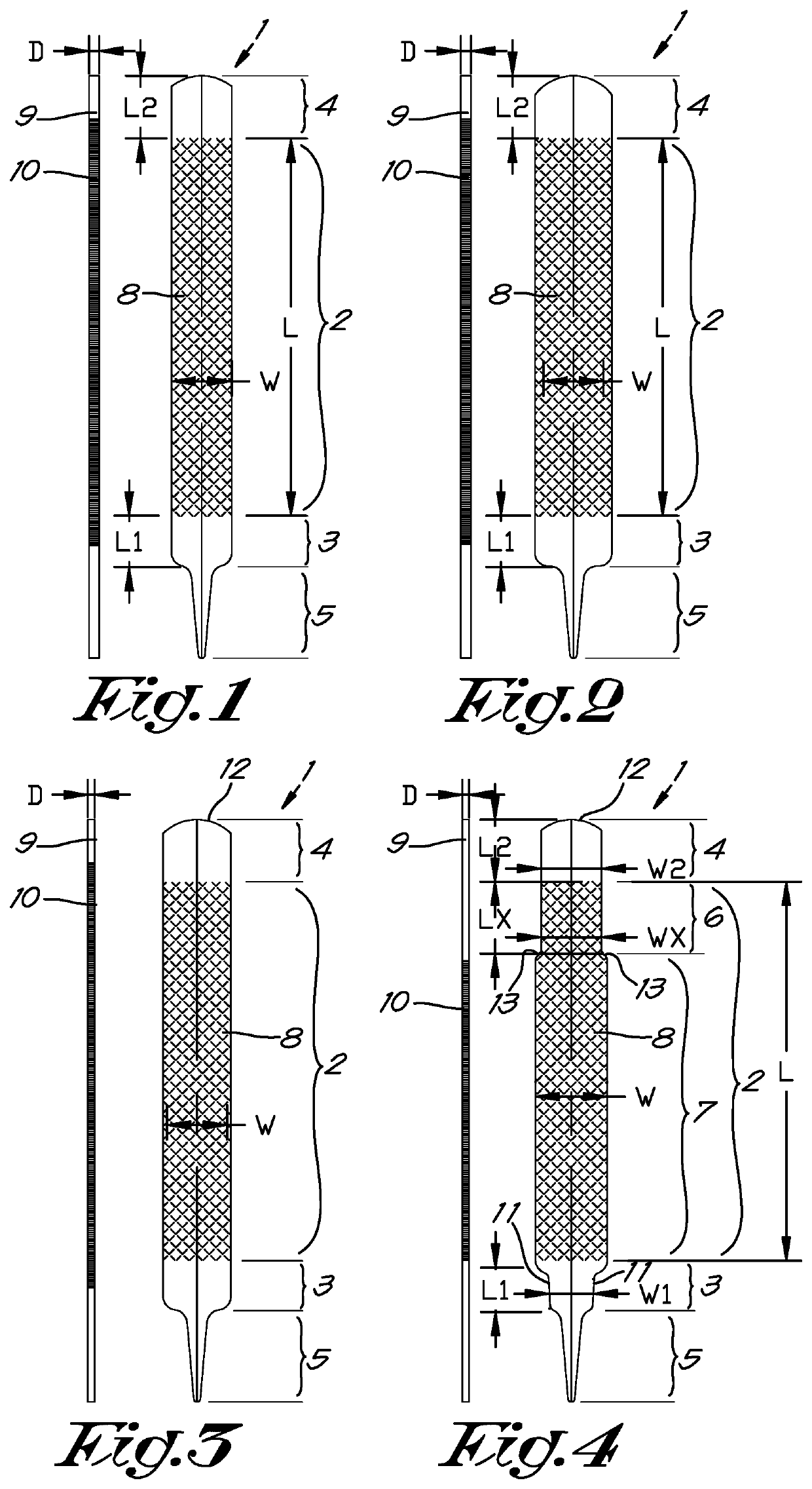

Hoof rasp

ActiveUS20200253183A1Softer initial strokeEasy to start raspingAnimal shoeingFiling/rasping toolsEngineeringMechanical engineering

Disclosed is a hoof rasp for filing / rasping and tidying the hoof of a horse, including at least one rasping side provided with a rasping section with length L and width W between a rasp-free first and second end over a respective length L1 and L2, whereby the first end tapers into a tang intended for a handle and the second end is for holding the hoof rasp, whereby the rasping section, toward the second end, includes a narrowed area. Also disclosed is a method for filing / rasping a hoof with such a hoof rasp.

Owner:KERCKHAERT HOEFIJZERFAB BV

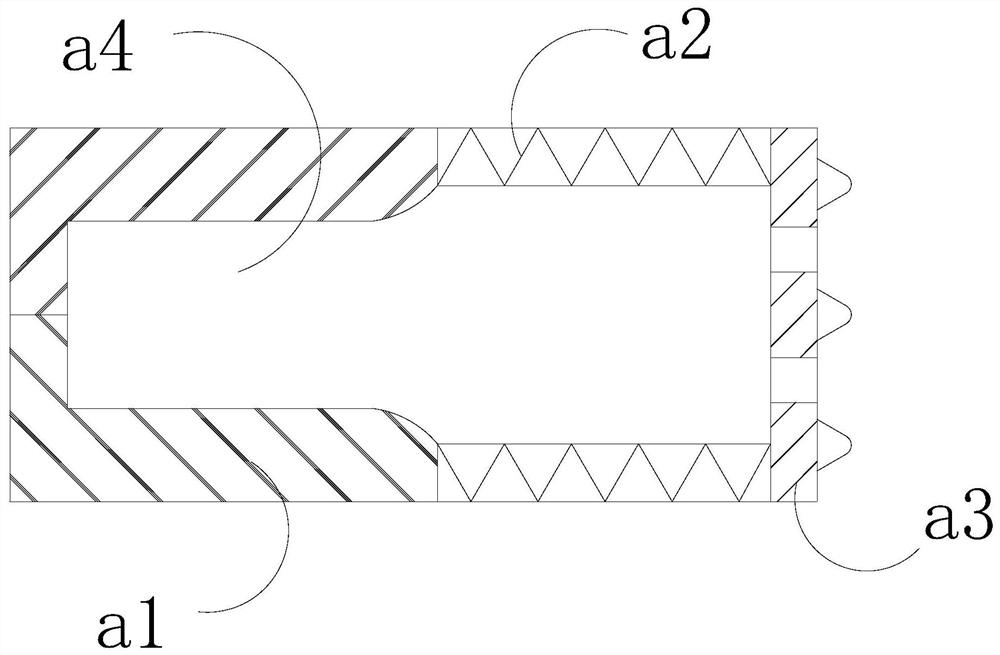

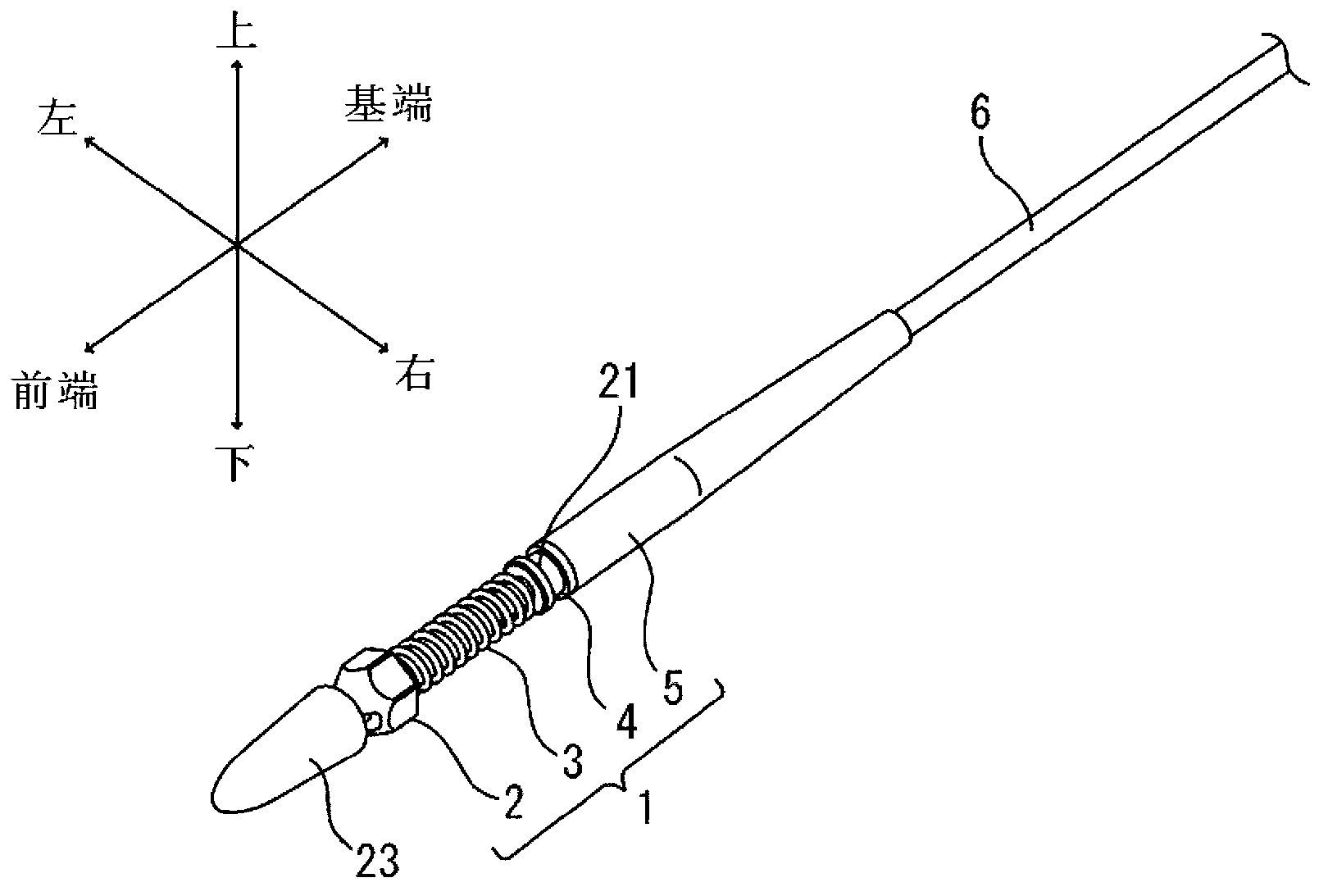

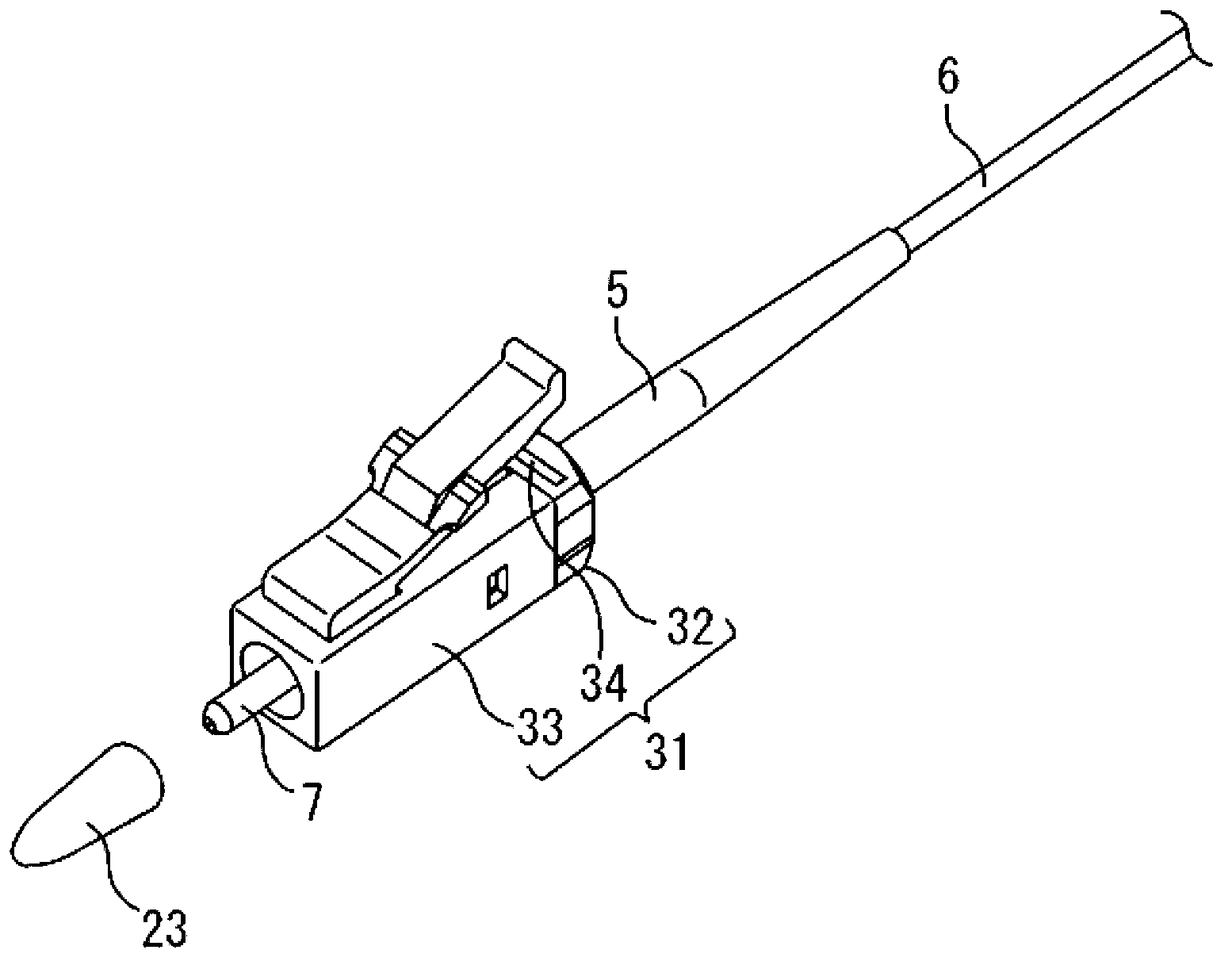

Optical fiber connector component and optical fiber connector provided with optical fiber connector component

InactiveCN103189771ASmall form factorEfficient insertionOptical fibre/cable installationCoupling light guidesEngineeringOptical fiber connector

Provided are an optical fiber connector component which holds an optical fiber and is capable of being inserted through a thin pipe and capable of being inserted smoothly through a pipe, and an optical fiber connector provided with the optical fiber connector component. The optical fiber connector component comprises a ferrule having a fiber hole to hold an inserted coaxially disposed optical fiber, a stop ring arranged on the base end side of the ferrule, and an urging means arranged in between the ferrule and the stop ring; the optical fiber connector is characterized by having a housing and cover member coaxially connected to the optical fiber, and the cover member being fixed to the stop ring of the optical fiber component by means of a fixing member.

Owner:NAMIKI PRECISION JEWEL CO LTD

Electronic device and screen folding and unfolding control method of electronic device

PendingCN113596205AReduce structural complexityLess stuckPower managementTelephone set constructionsElectric machineryEngineering

The invention discloses an electronic device and a screen folding and unfolding control method of the electronic device. The two sides of a body of the electronic device are a first side and a second side, a flexible screen is wound on the body from the first side, the flexible screen is provided with a first screen side and a second screen side, the first screen side is arranged on the front face of the body, and the second screen side is arranged on the back face of the body. The main shaft is rotatably arranged on the body, and the driver is connected with the main shaft. The energy accumulator is arranged on the body and provided with a telescopic rod, one end of the telescopic rod is connected with one side of the flexible screen, and the energy accumulator drives the telescopic rod to move in the direction away from the side when releasing energy. One end of the first rope body is connected with two sides of the screen and the other end is wound on the main shaft. One end of the second rope body is connected with the telescopic rod, and the other end is wound on the main shaft. The control valve is connected with the spindle. According to the electronic device, the probability that the driver is stuck (such as motor stalling) can be effectively reduced, the electric quantity is saved, and the probability that the screen is rolled and swells can be reduced.

Owner:WINGTECH COMM

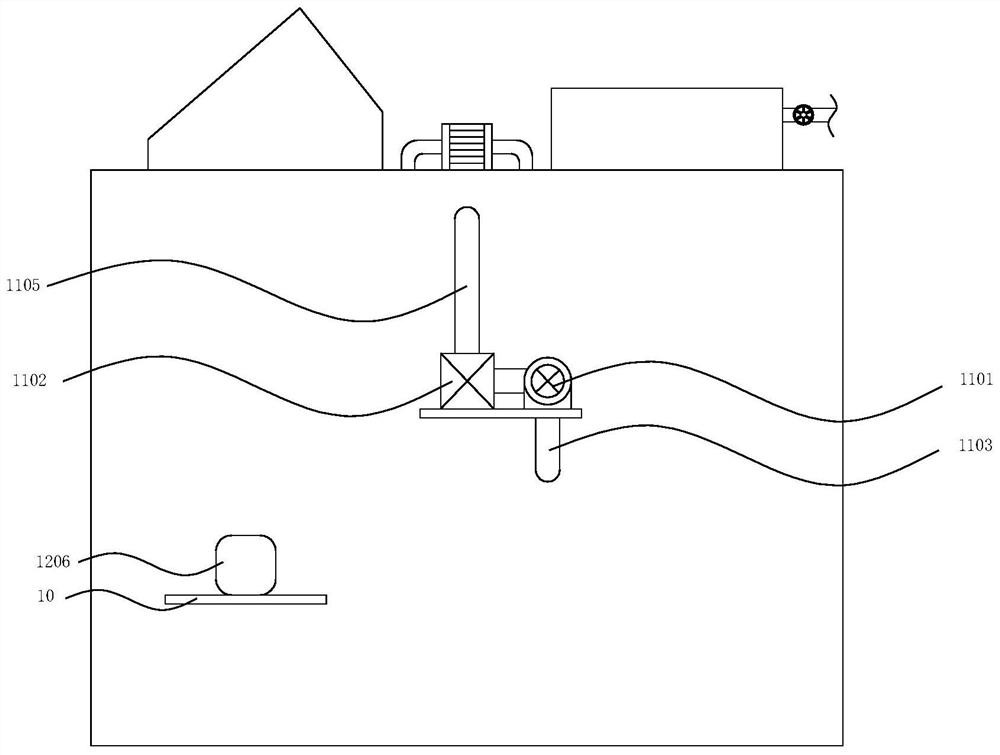

Water conservancy and hydropower dam water inlet floating object cleaning device

InactiveCN114032847ALess stuckReduce moistureSolid waste disposalArtificial water canalsEnvironmental engineeringMechanical engineering

The invention discloses a water conservancy and hydropower dam water inlet floating object cleaning device, and belongs to the field of water conservancy and hydropower. The cleaning device comprises a box body, a conveying mechanism, a crushing mechanism and an extruding mechanism, the conveying mechanism is rotationally connected to the box body, the crushing mechanism and the extruding mechanism are fixedly connected to the box body, a driving mechanism is fixedly connected to the box body, the driving mechanism is rotationally connected with the conveying mechanism, and the driving mechanism is rotationally connected with the crushing mechanism and the extruding mechanism through the transmission mechanism. The device is easy to use and convenient to operate, garbage at the water inlet is collected, crushed and compressed, the garbage treatment efficiency is improved, accumulation of the garbage at the water inlet is reduced, the flow speed of the water inlet is increased, damage of the garbage to water conservancy equipment is reduced, meanwhile, the garbage is automatically crushed and discharged, the labor intensity of workers is relieved, and the working efficiency is improved.

Owner:刘土仙

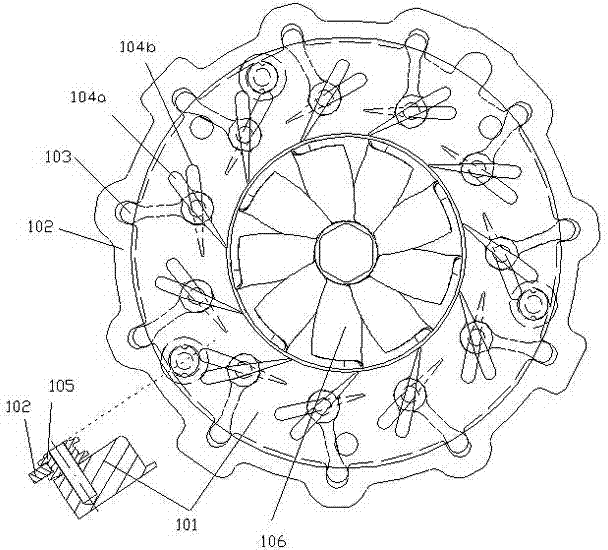

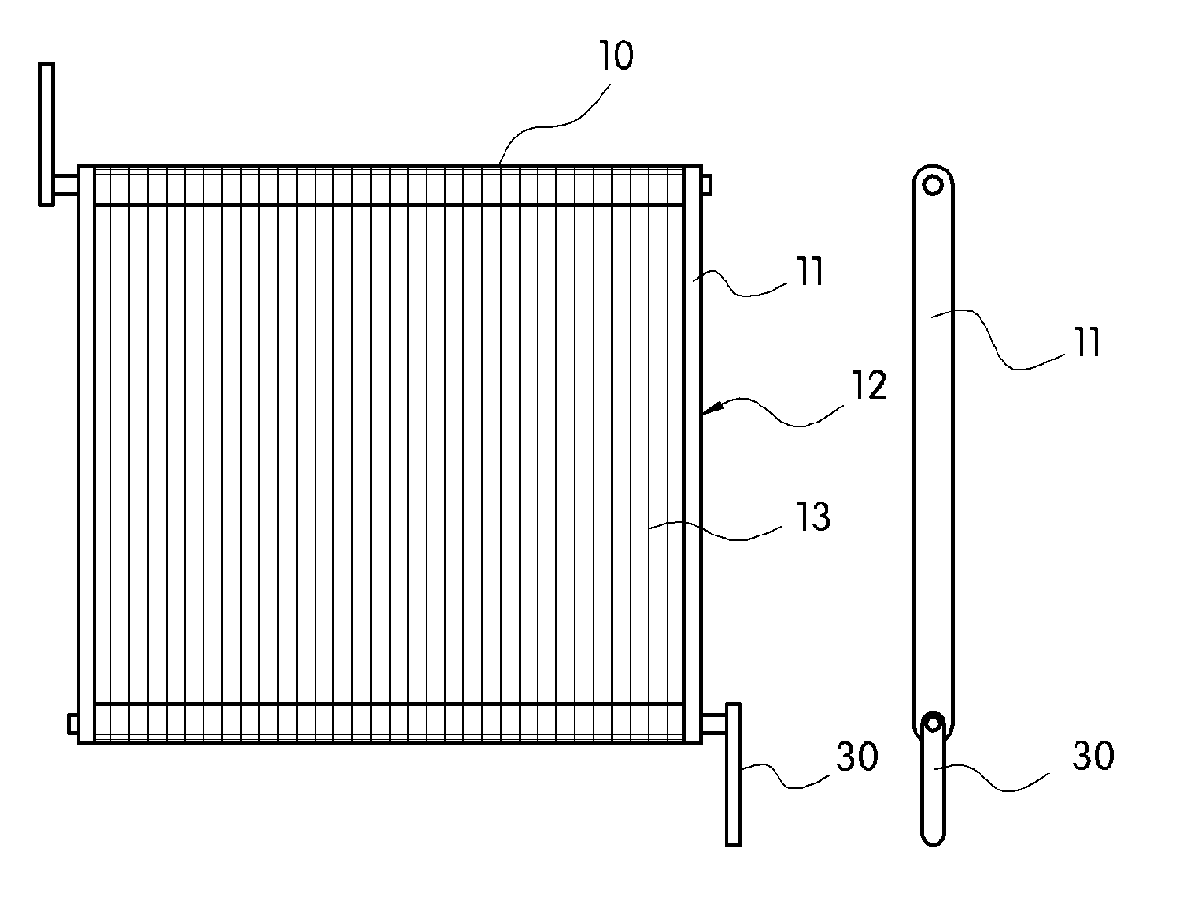

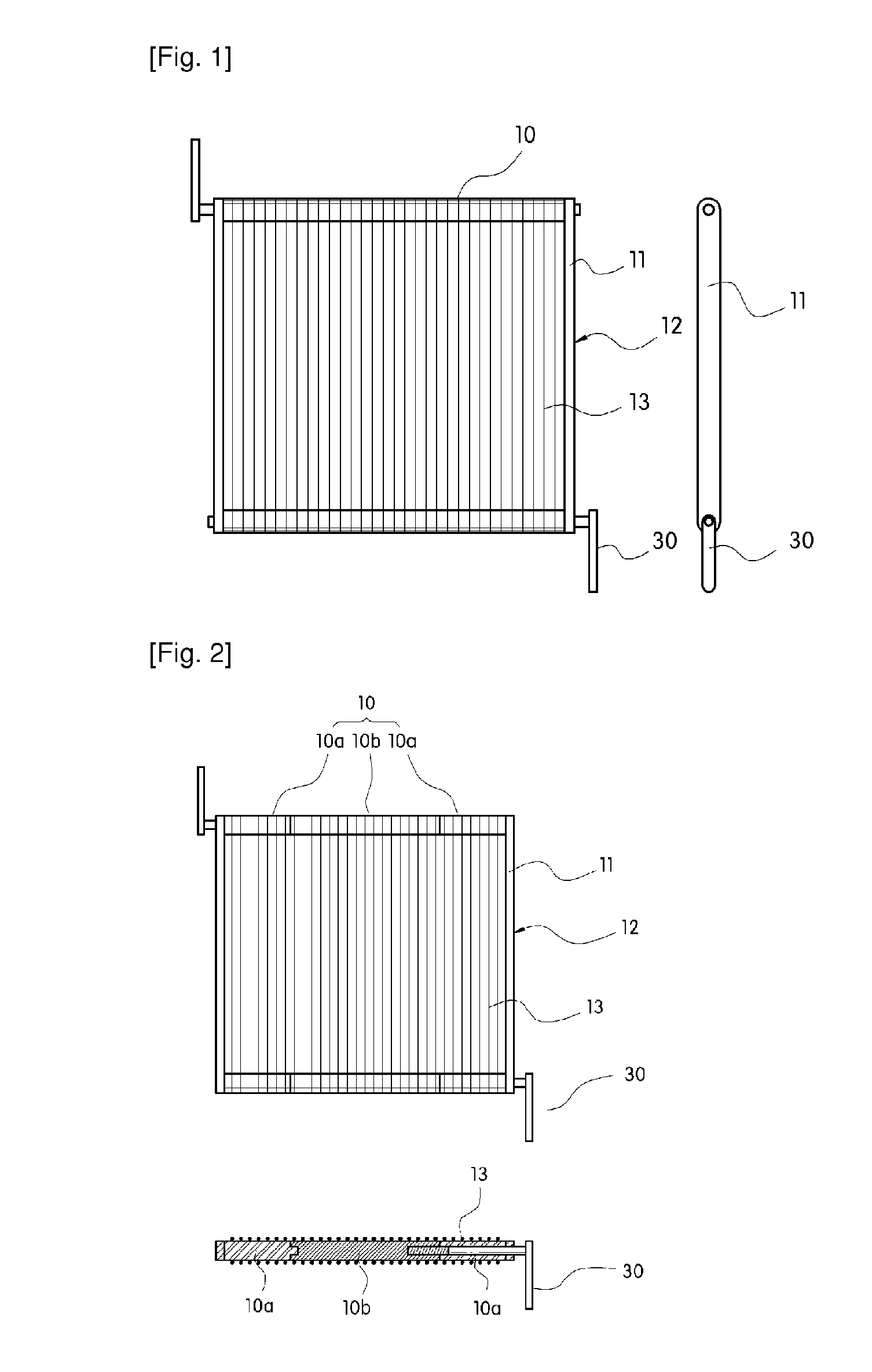

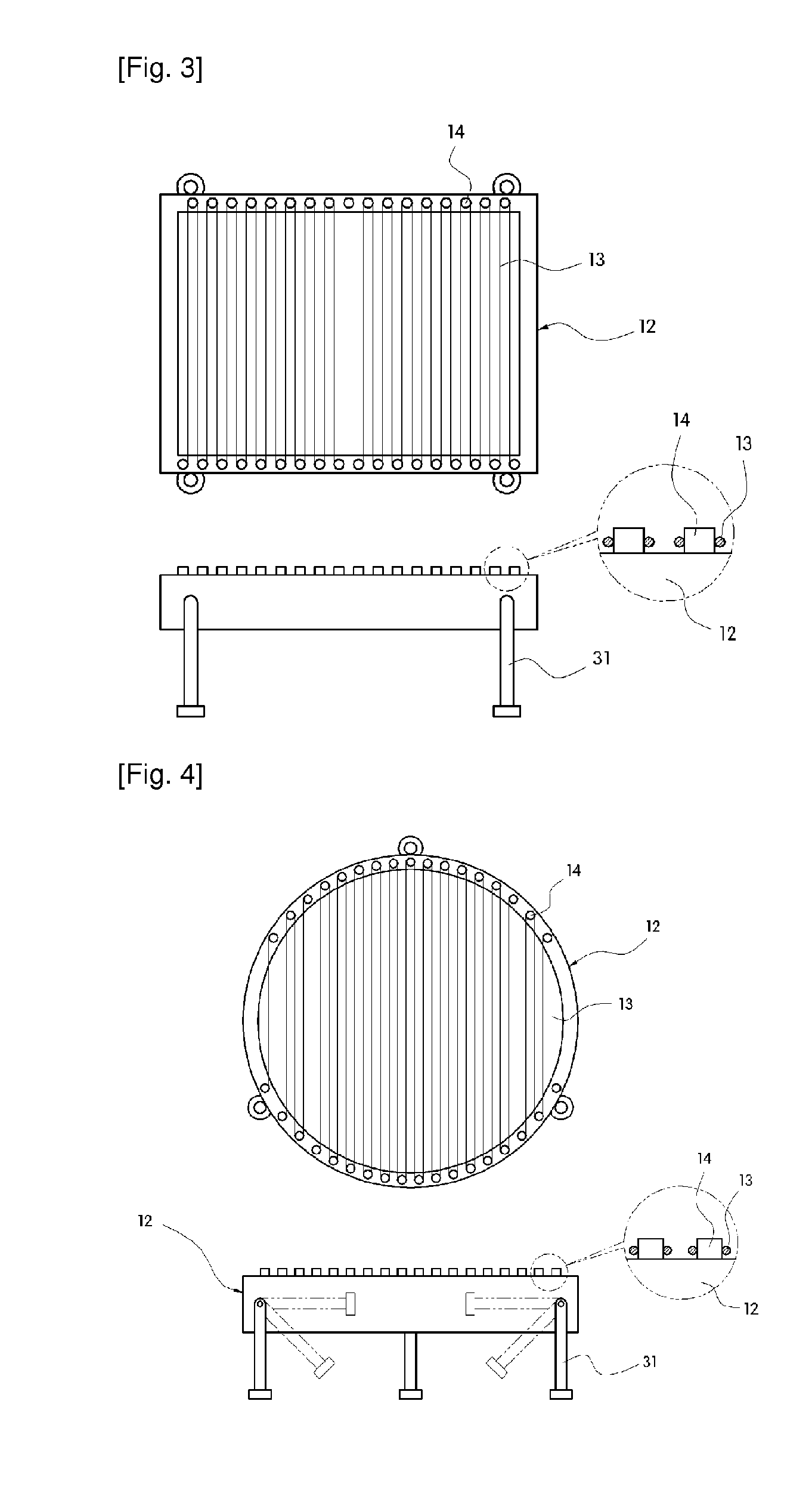

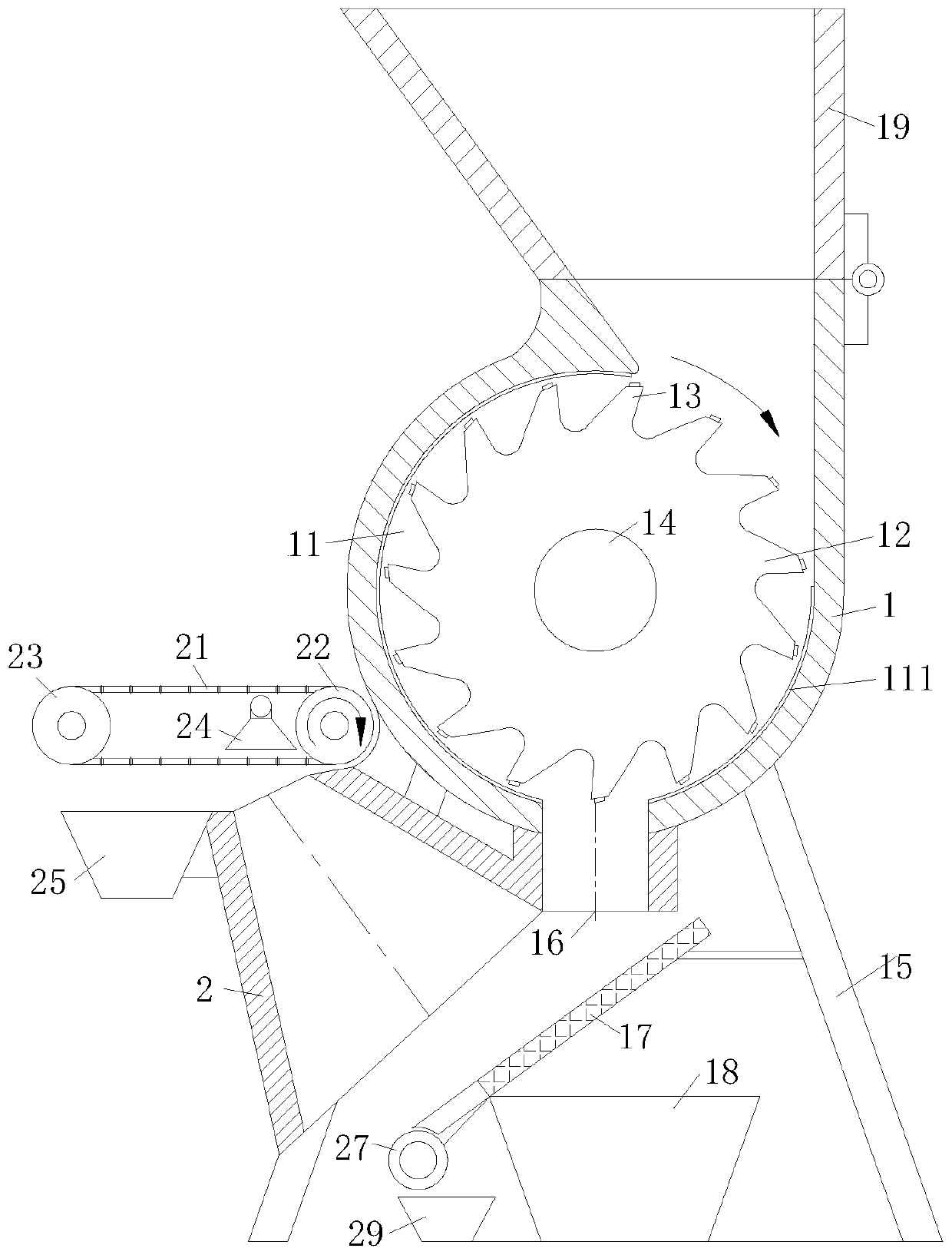

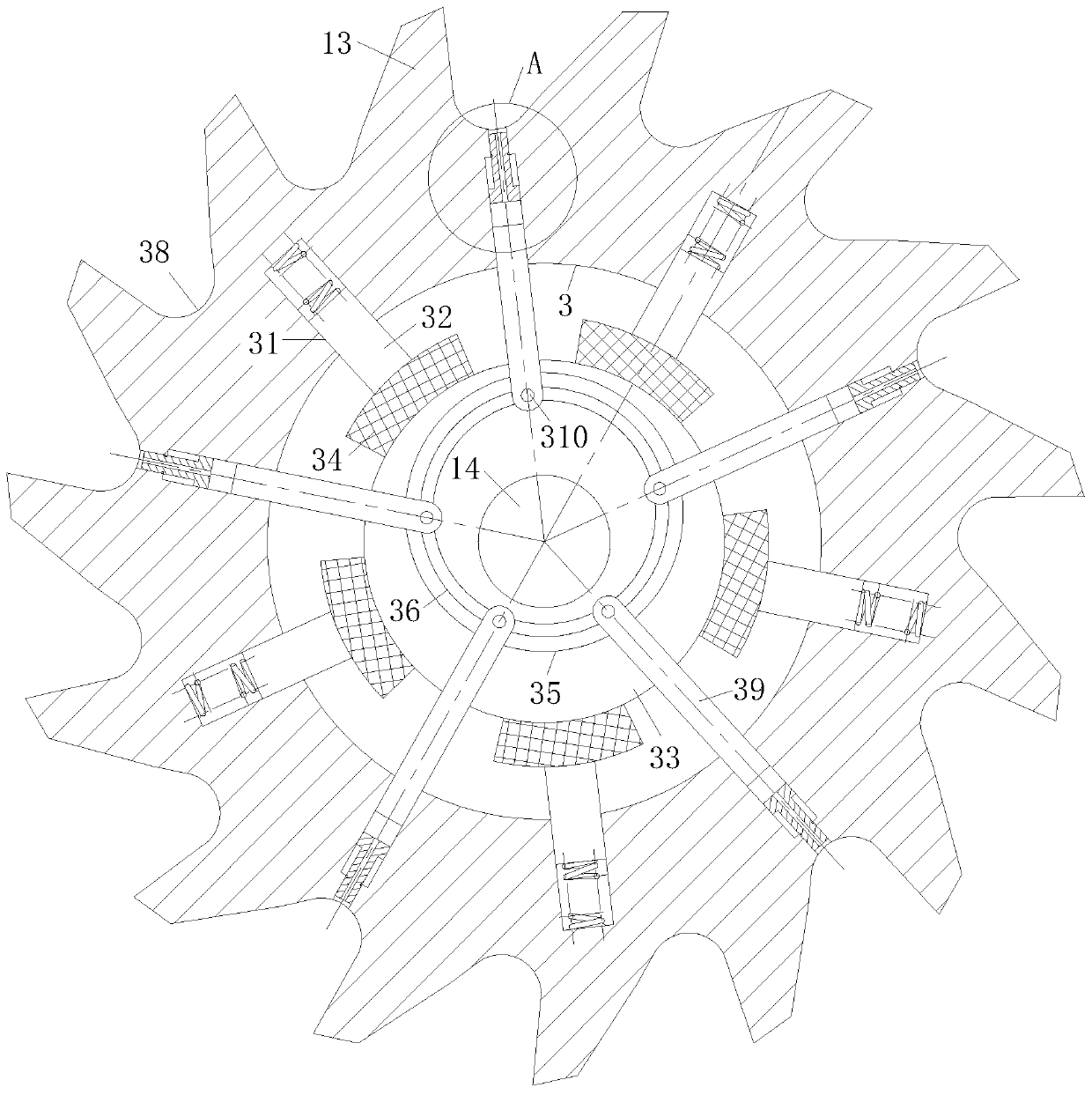

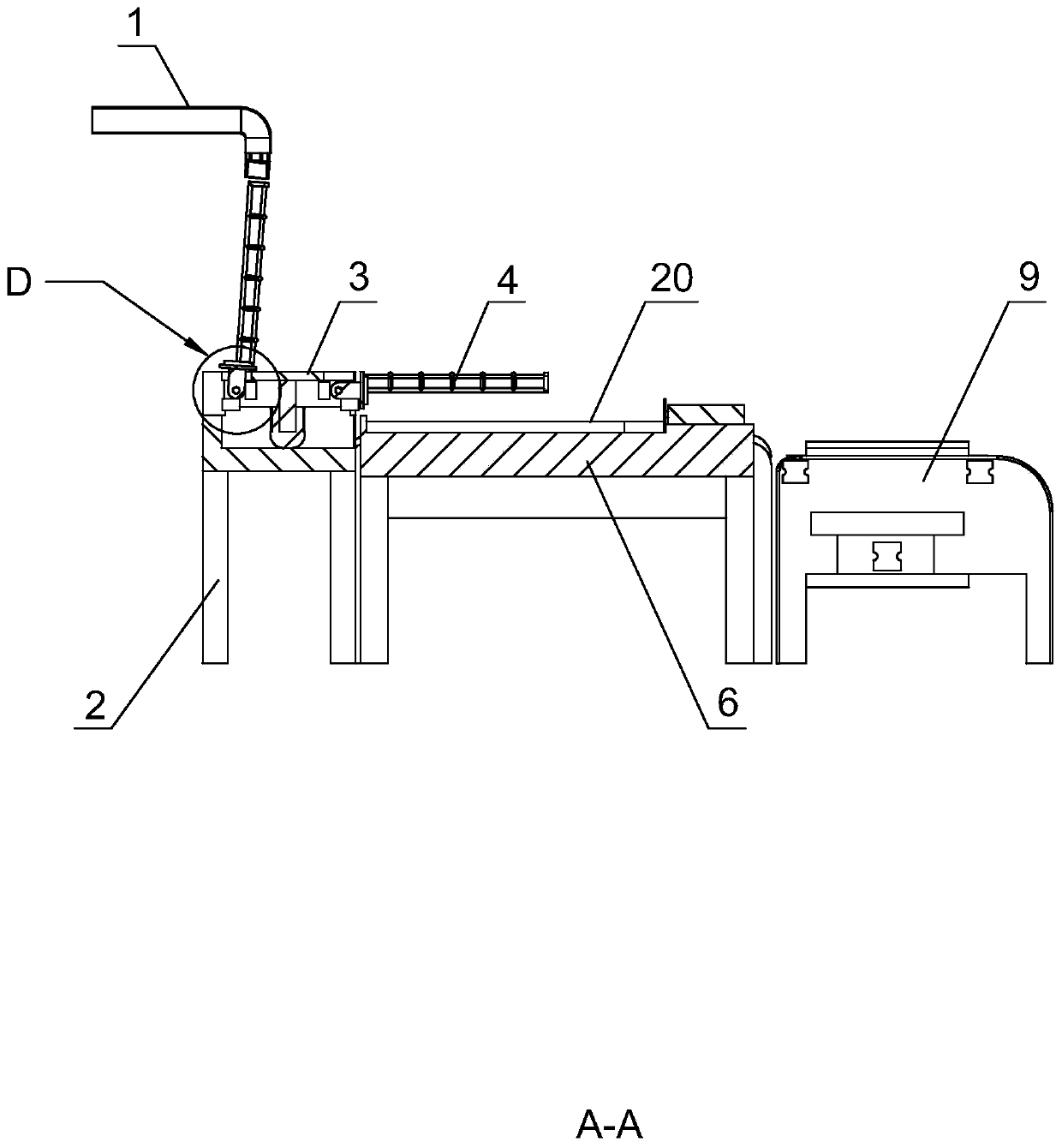

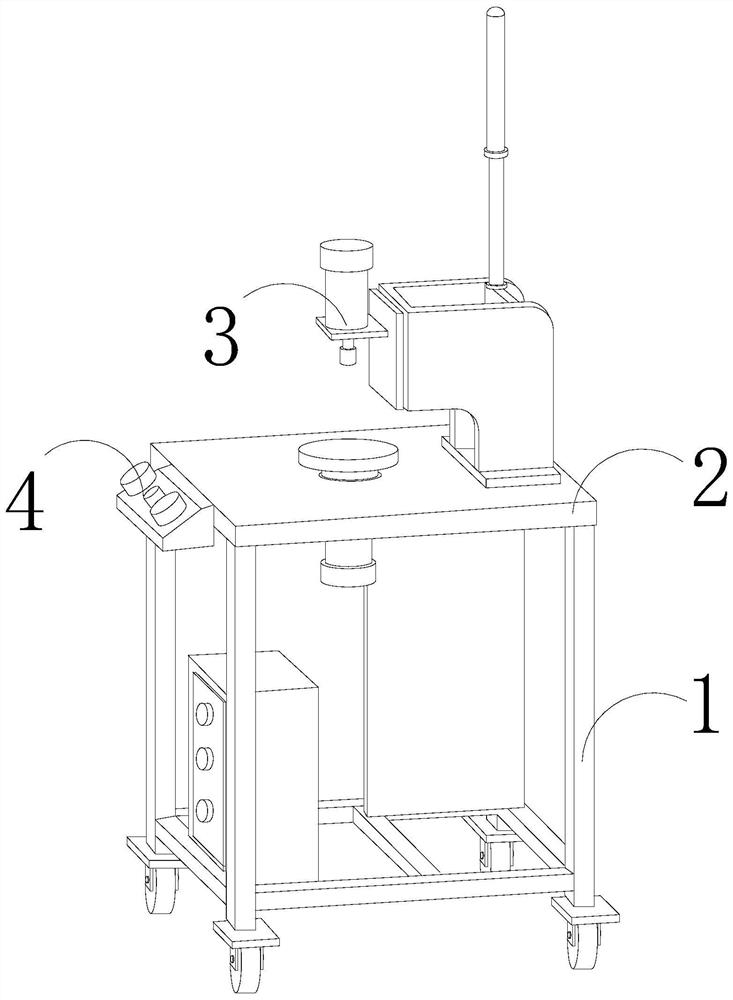

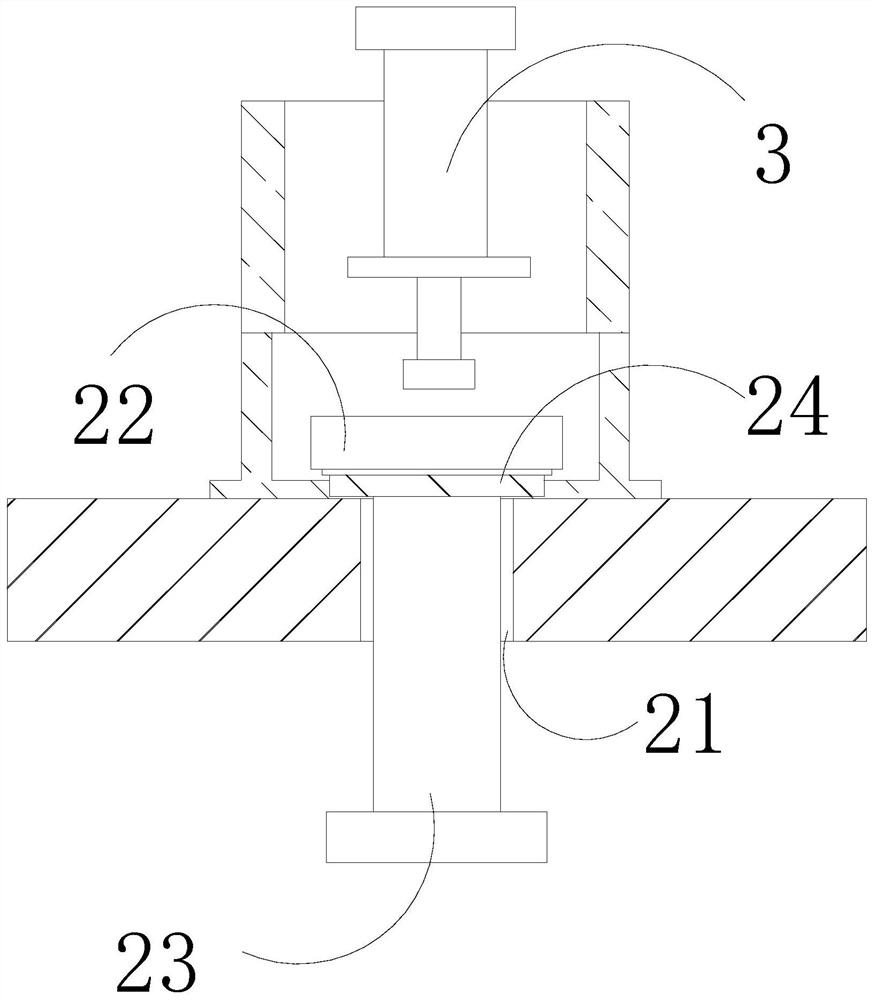

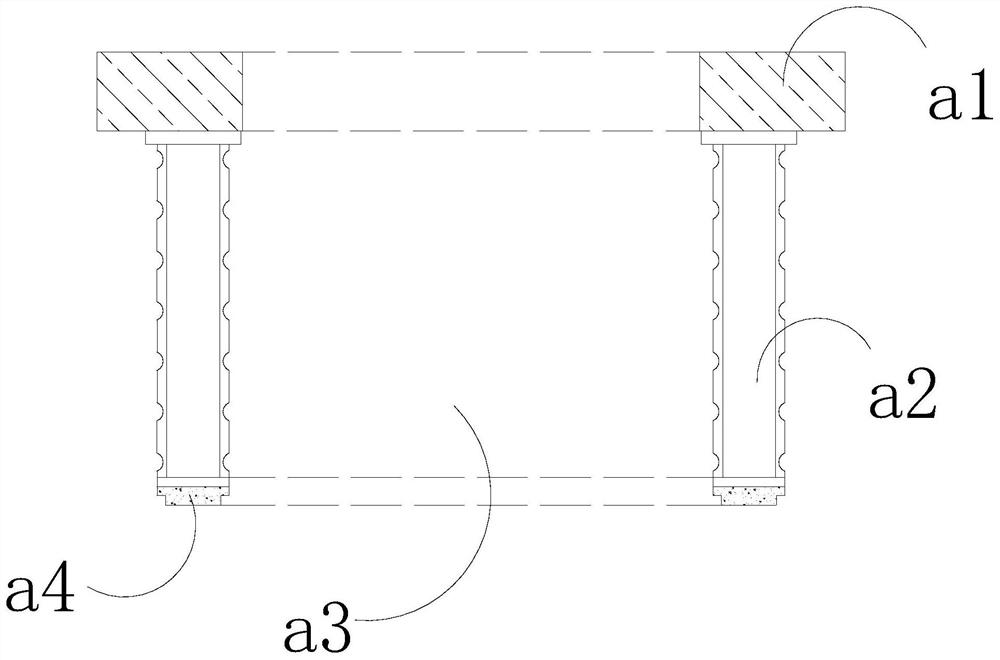

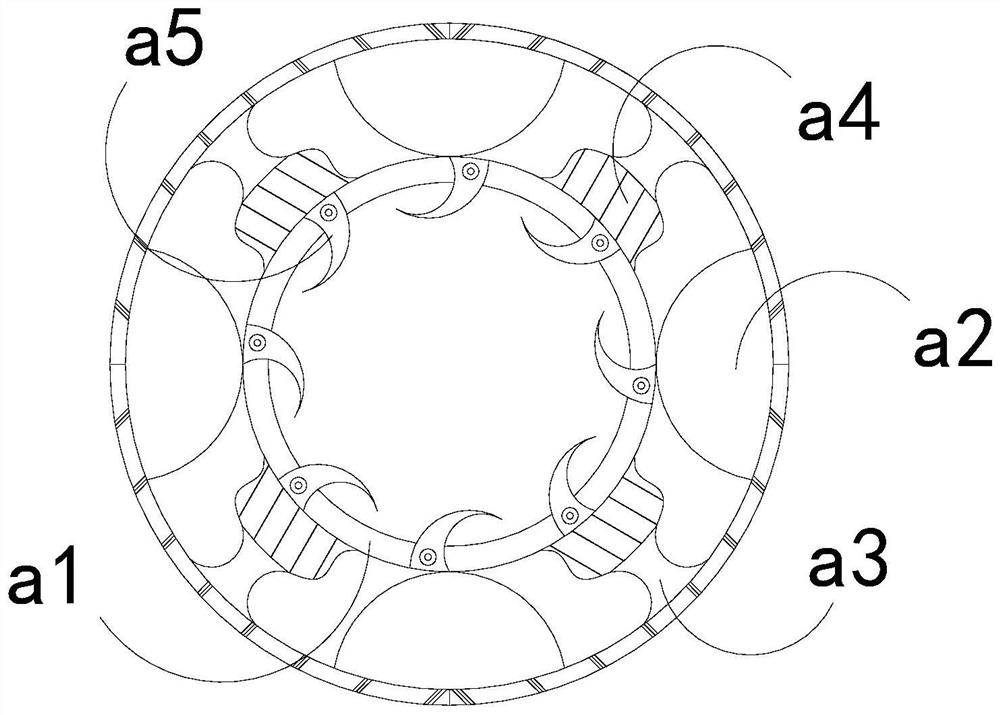

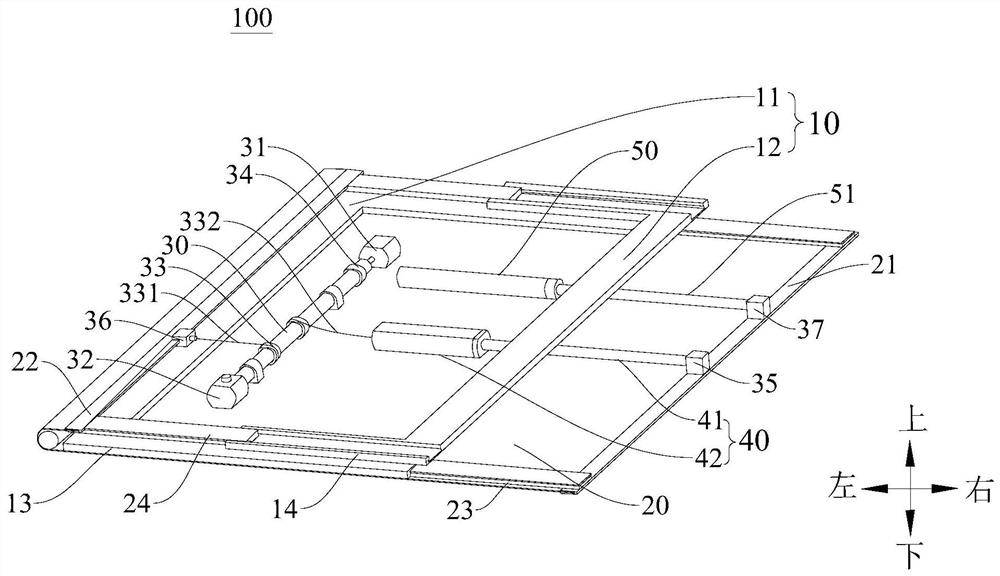

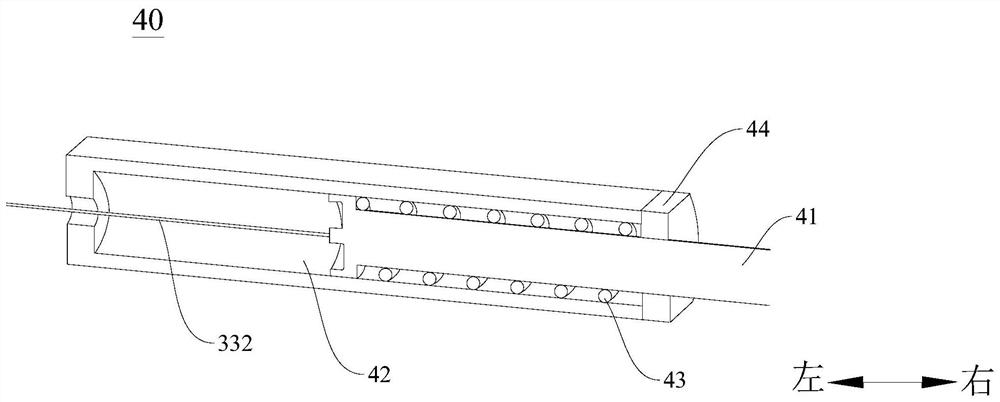

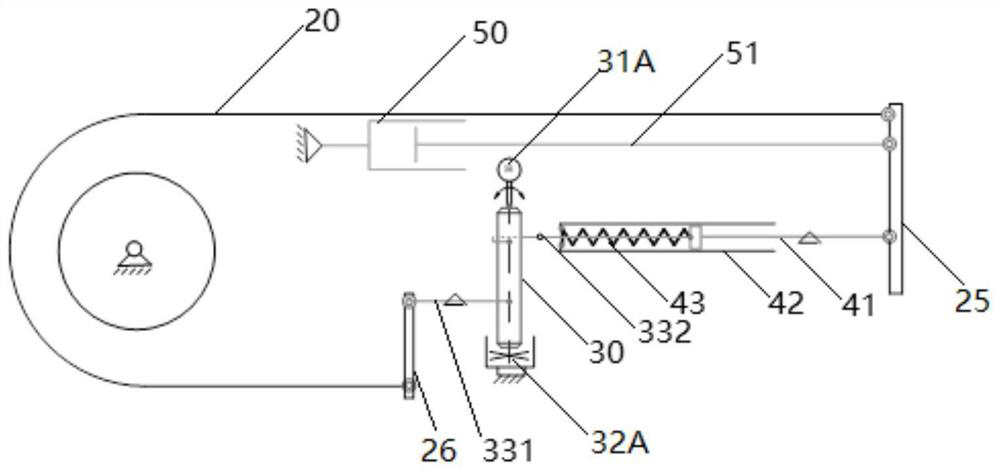

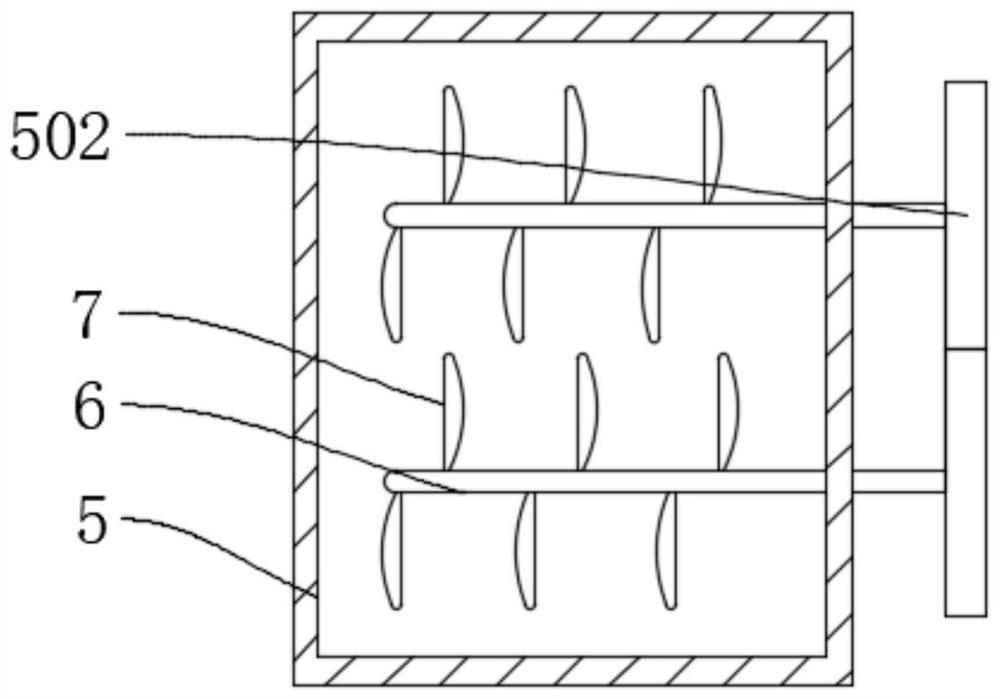

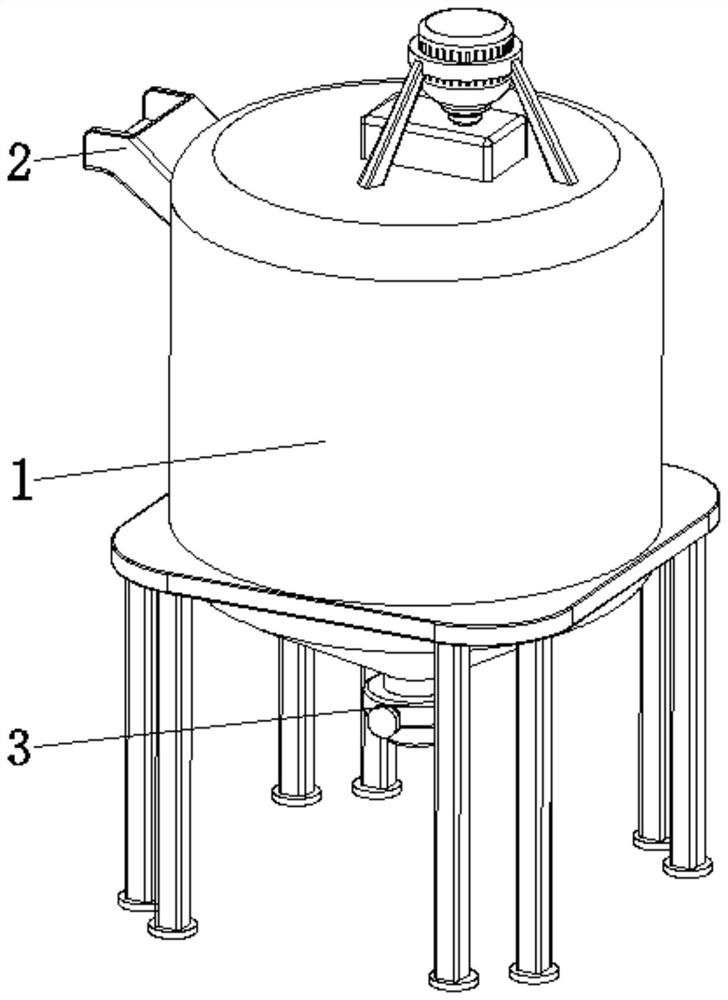

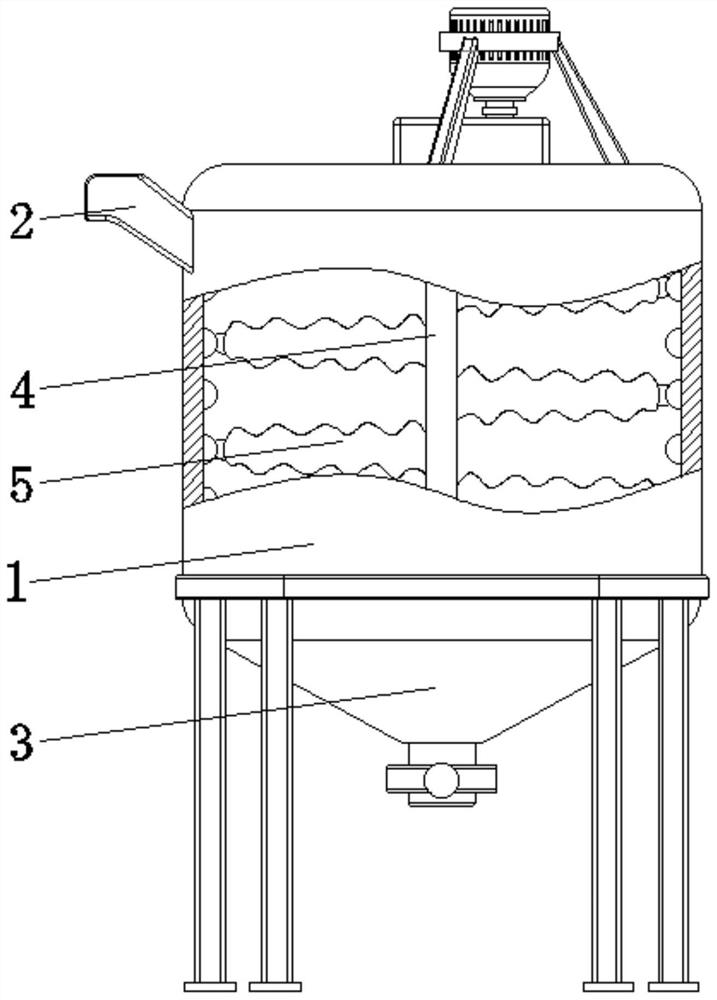

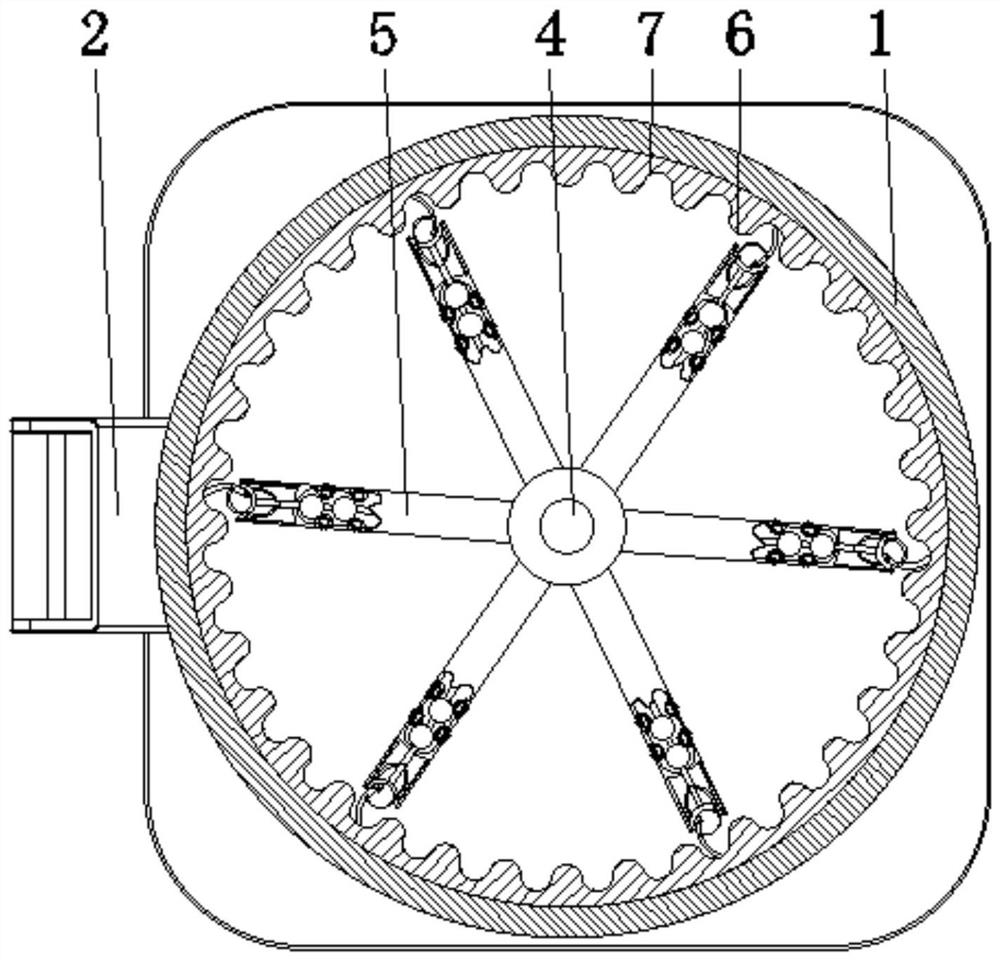

A three-degree-of-freedom hybrid vibrating screening device

ActiveCN105710026BLess stuckImprove productivitySievingScreeningProduction rateThree degrees of freedom

The invention discloses a three degree-of-freedom hybrid vibration screening device, and relates to the field of vibration screening. The three degree-of-freedom hybrid vibration screening device is mainly used for screening and cleaning materials, and comprises a screen shoe, a plane multiple-bar linkage, a movable table board and a series branched chain. Power is provided for the screening device by adopting a linear motor. The screening device has three degrees of freedom, that is, two transitions and one rotation, material particles in the screen shoe can be sufficiently overturned and screened, the phenomenon that a screen hole is jammed by the screened particles is reduced, the efficient screening of the materials can be realized, the problem that the materials are not sufficiently cleaned in industry and agriculture is solved, the screening efficiency is improved, and the production efficiency of the whole screening device is improved.

Owner:宣城九龙钙业有限公司

Concrete processing equipment

InactiveCN112917680AReduce solidificationLess stuckCleaning using gasesCement mixing apparatusArchitectural engineeringStructural engineering

The invention discloses concrete processing equipment. The concrete processing equipment comprises a mixing bin, a feeding hopper and a discharging hopper, wherein the feeding hopper is arranged at one side of the top surface of the mixing bin, the discharging hopper is arranged in the center position of the bottom of the mixing bin, a driving rotating shaft is rotatably connected between two corresponding sides of the top and bottom inner walls of the mixing bin, stirring devices are fixed to a surface of the driving rotating shaft, arc-shaped wave crests and arc-shaped wave troughs are all arranged on an inner wall of the mixing bin, and are arranged in a staggered mode in a circumferential direction of the corresponding inner wall of the mixing bin, and the ends, away from the driving rotating shaft, of the stirring devices are connected with the arc-shaped wave crests and the arc-shaped wave troughs in a matching mode. The invention relates to the technical field of concrete processing. According to the concrete processing equipment, the purposes of jamming prevention and self-cleaning are achieved, the situation of jamming can be avoided, thus the service life is prolonged, and meanwhile, self-cleaning can be conducted, so that concrete adhesion is reduced, stirring is facilitated, and the working efficiency and the use performance are improved.

Owner:赵惠君

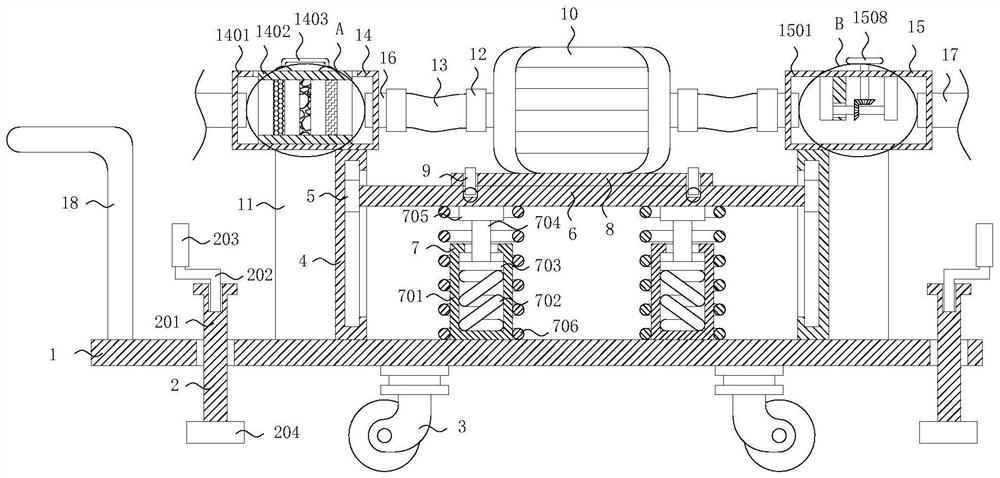

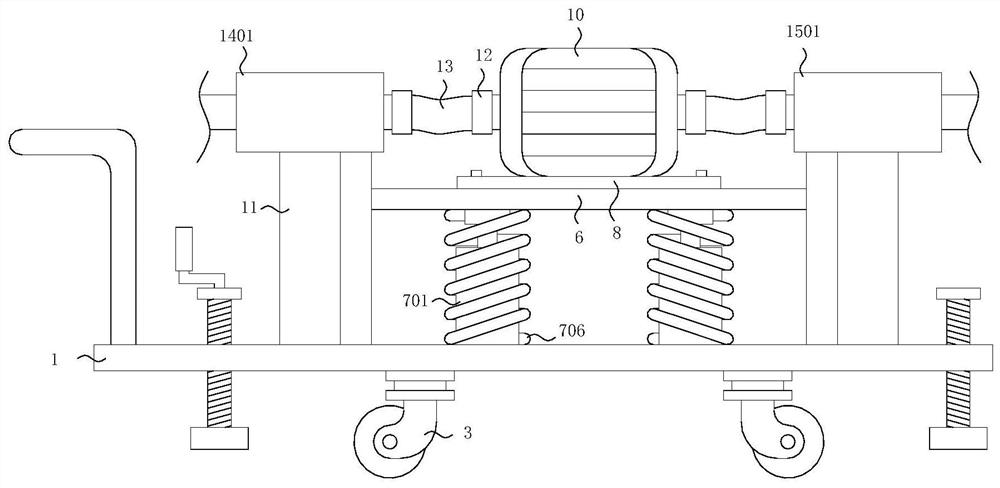

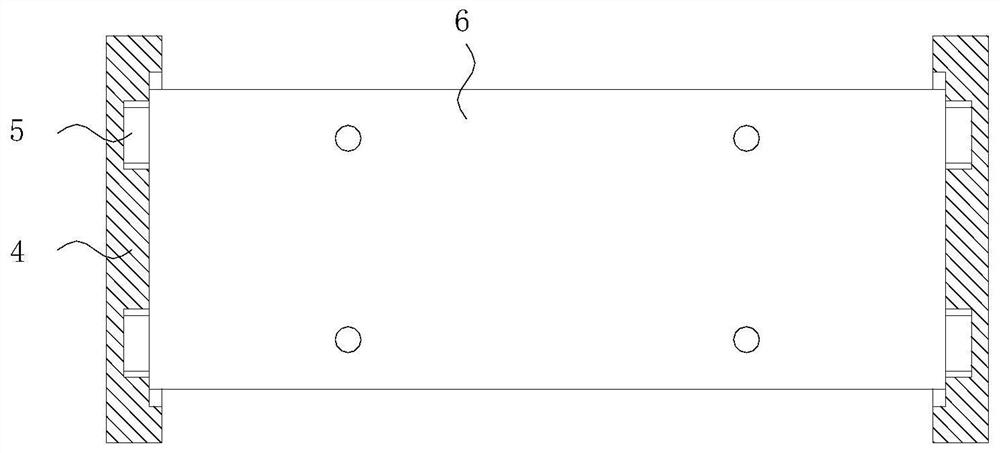

Cooling fan bottom damping device applied to Hooke law

ActiveCN112096642AReduce work intensityReduce the laborious problem of manual handlingPortable framesPump componentsWorking environmentAcoustics

The invention discloses a cooling fan bottom damping device applied to Hooke law, and relates to the technical field of fans. The cooling fan bottom damping device applied to the Hooke law comprises atransverse plate, wherein fixing mechanisms are arranged on the transverse plate, moving wheels are movably arranged at the bottom of the transverse plate, and a damping plate is arranged above the transverse plate. According to the cooling fan bottom damping device applied to the Hooke law, through cooperative use of damping boxes, reset springs, movable plates, connecting rods, connecting blocks and damping springs, when a fan is started for use, vibration can be generated during work of the fan, and then vibration generated by the fan is damped, so that damage to internal parts of the fandue to long-time vibration is reduced, repair and maintenance of the fan in a short time is reduced, noise generated during vibration of the fan is also reduced, the influence of noise generated by the fan on hearing of people around due to loud volume is reduced, the working environment used by people is guaranteed, and the practicability of the damping device is enhanced.

Owner:HEBEI QIANHAI BLOWER MFG

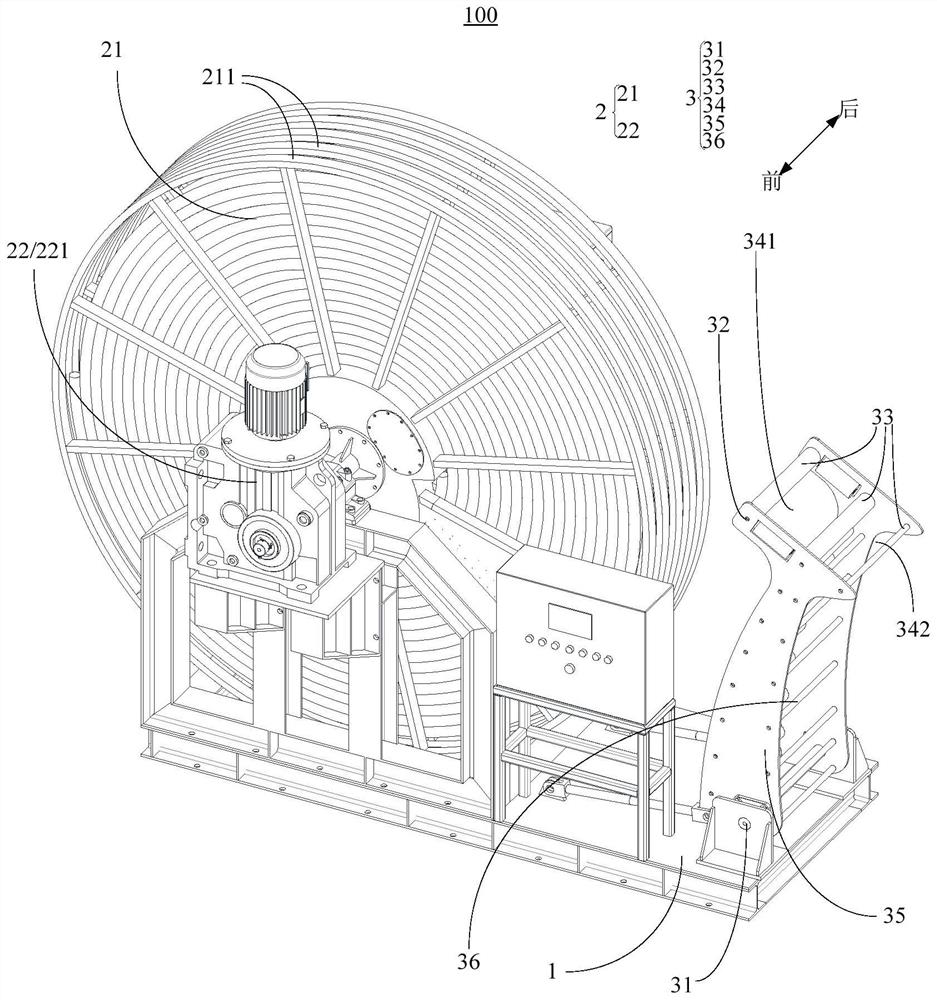

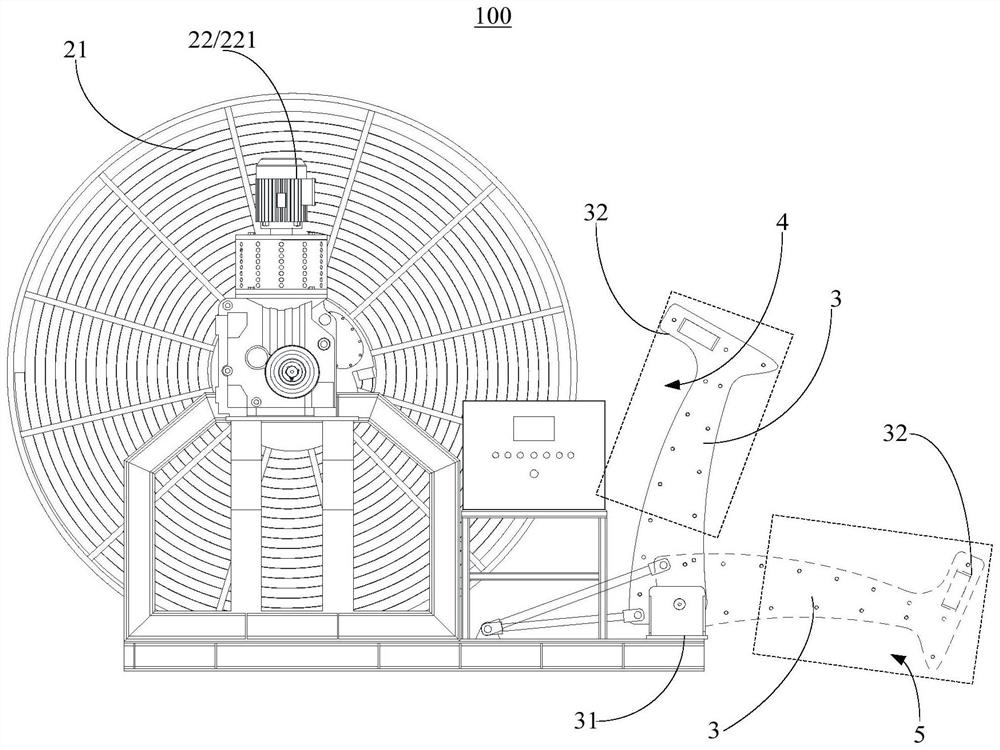

Cable winch and power supply system

The invention discloses a cable winch and a power supply system. The cable winch comprises a mounting base, a winding device and a guide piece. The winding device comprises a winding drum rotationally mounted above the mounting seat and a driving device in driving connection with the winding drum, and the driving device is used for driving the winding drum to rotate so as to collect or release the cable; the guide part is provided with a mounting end mounted on the mounting seat and a guide end extending out of the mounting seat, a plurality of guide rollers are oppositely arranged at the guide end at intervals, and gaps among the guide rollers form guide channels. When the cable passes through the guide channel, the guide end extends out of the mounting seat, so that the cable is pulled to a position spaced from the ground and the mounting seat to be wound and unwound, the contact between the cable and the ground and the mounting seat when the cable passes through the guide channel to be wound and unwound is reduced, and the possibility that the cable is clamped can also be reduced.

Owner:WUHAN JINDING ELECTRICAL EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com