Optical fiber connector component and optical fiber connector provided with optical fiber connector component

一种光纤连接器、部件的技术,应用在光纤连接器领域,能够解决光纤连接器损坏、光纤断裂、光纤连接器易卡住等问题,达到减少卡住、容易插入的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0097] Installation of fiber optic connector components:

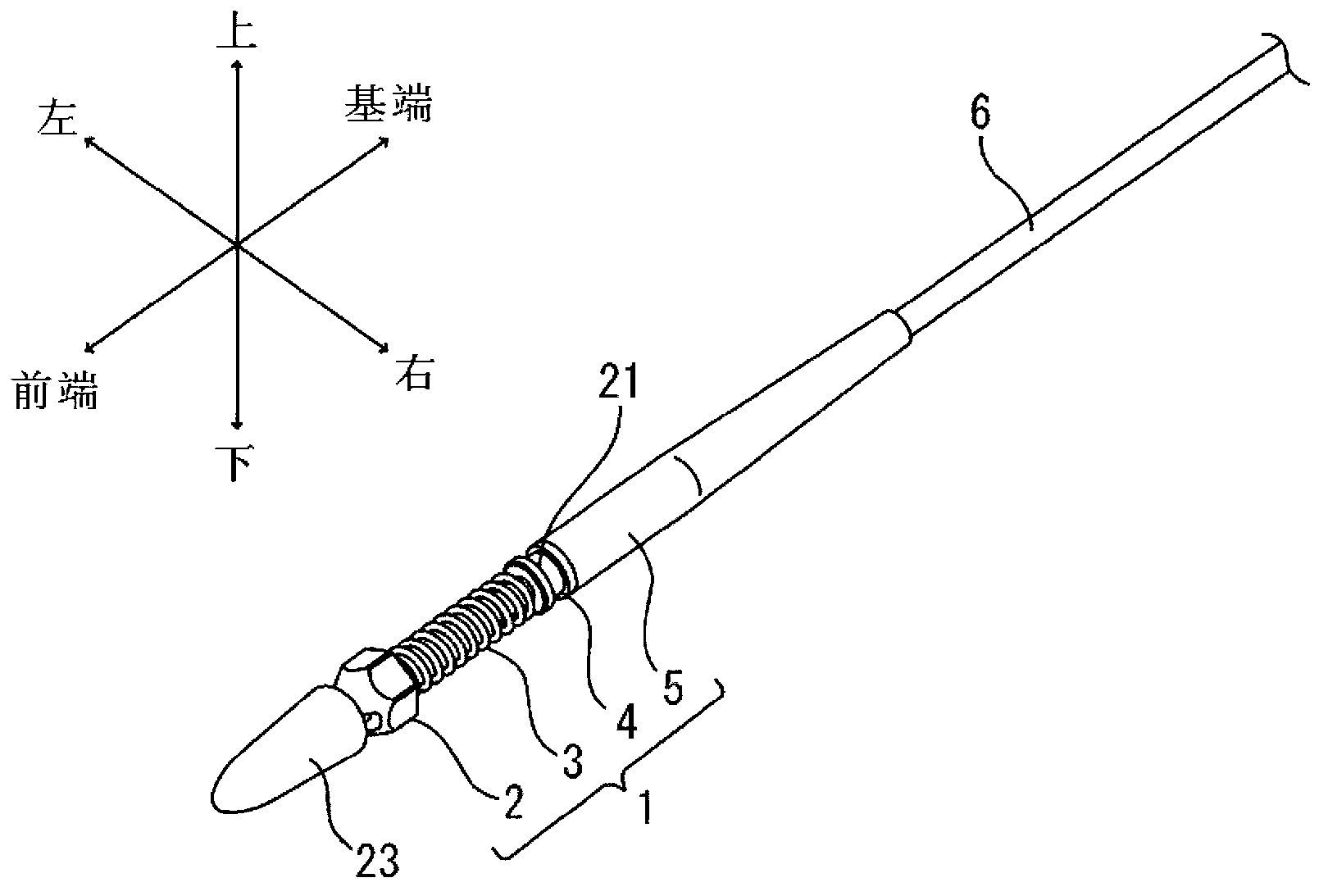

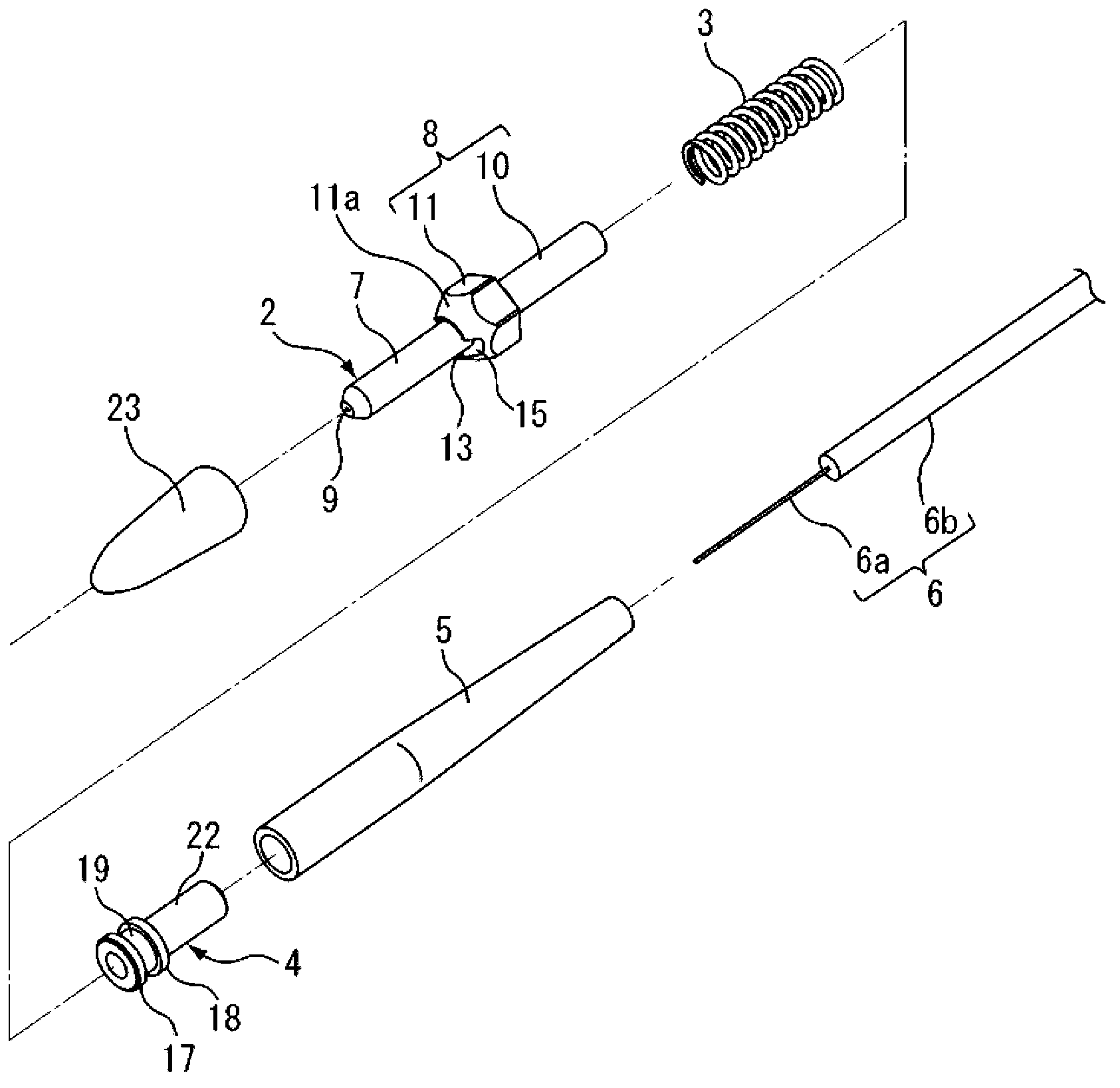

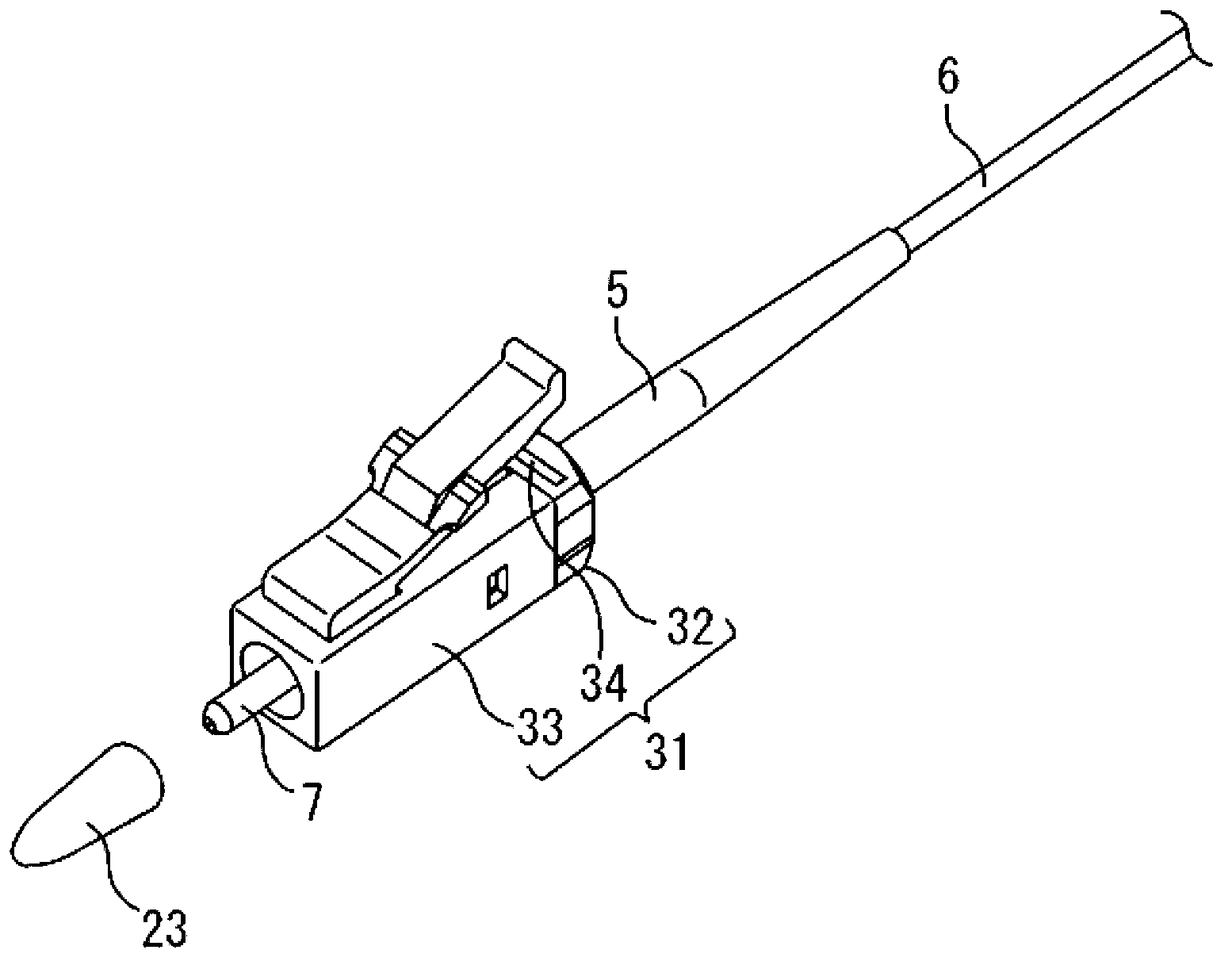

[0098] In this example, an optical fiber having a diameter of 0.9 mm and a length of 200 m was prepared. Next, the boot 5, snap ring 4 and coil spring 3 are sequentially inserted from the front end of the optical fiber 6, and after insertion, the coating material at the front end of the optical fiber 6 is removed to expose the optical fiber core wire 6a. Next, the front end of the optical fiber 6 is inserted into and held in the ferrule 2 , and the cap 23 is attached to the front end of the ferrule main body 7 . In addition, the stop ring 4 in Example 1 uses a product with a rib plate at the front end, and the optical fiber 6 uses a product with no special processing on the surface of the cladding material.

[0099] (transportation test)

[0100] Next, a pay-off machine for discharging the optical fiber 6 is prepared, and the optical fiber 6 with the optical fiber connector component 1 attached to the tip is assemble...

Embodiment 2)

[0102] In the second embodiment, except that the boot 5 is not used, the optical fiber connector component 1 is installed on the optical fiber 6 in the same manner as the first embodiment. Next, a transport test was performed under the same conditions as in Example 1. The transport test results of Example 2 are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com