Wrench polishing equipment for hardware

A wrench and equipment technology, applied in the field of hardware wrench polishing equipment, can solve problems such as the influence of the lifting height of the support plate, the jamming of the push rod and the thread groove, and the distance between the wrench and the polisher, etc. The effect of little resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

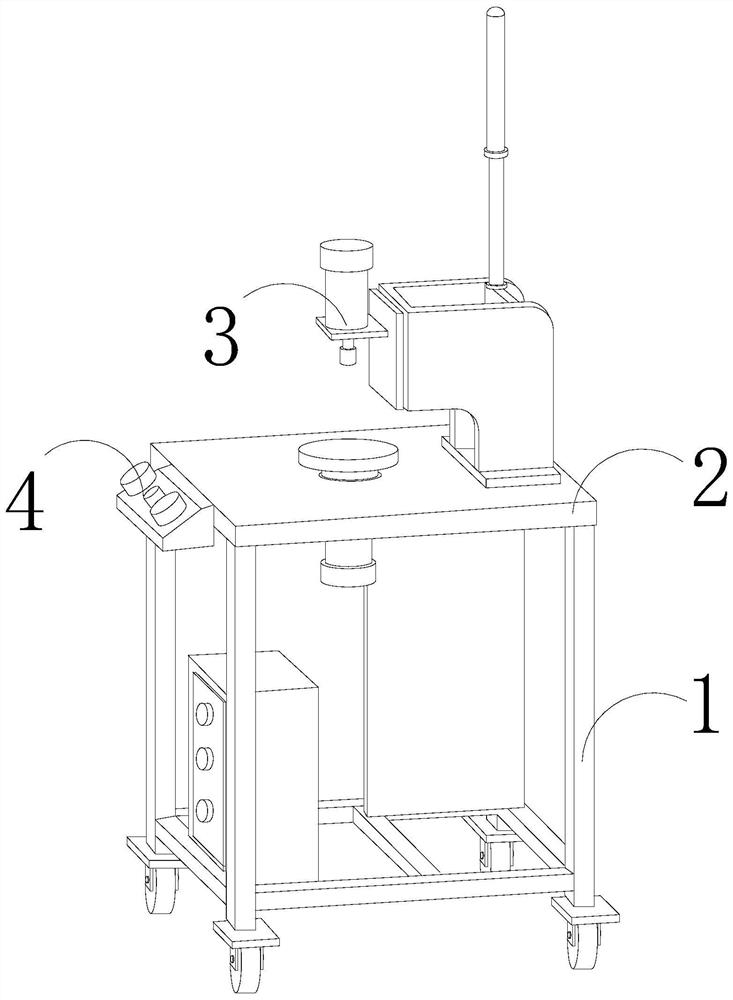

[0027] as attached figure 1 To attach Figure 5 Shown:

[0028] The invention provides a wrench polishing equipment for hardware, the structure of which includes a support frame 1, a polishing table 2, a polisher 3, and a controller 4, the polishing table 2 is horizontally welded on the top of the support frame 1, and the polisher 3 is installed on The top of the polishing table 2, the controller 4 is arranged in the middle of the front of the polishing table 2.

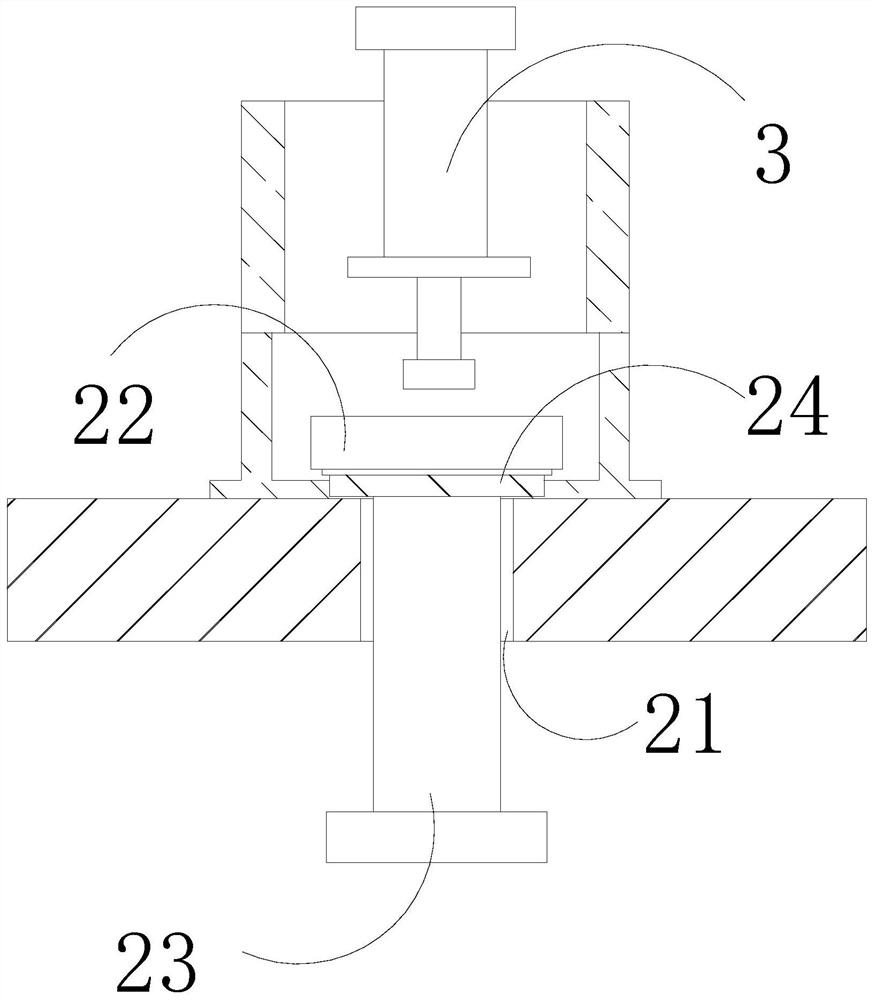

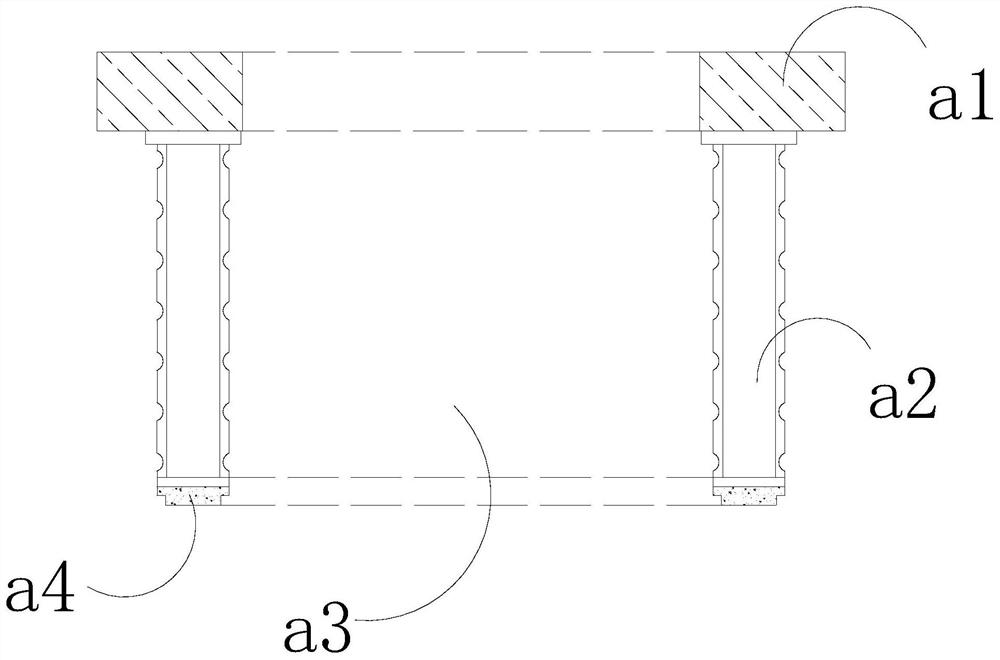

[0029] The polishing table 2 is provided with a thread groove 21, a support plate 22, a push rod 23, and a blocking mechanism 24. The thread groove 21 runs through the upper and lower surfaces of the middle part of the polishing table 2, and the support plate 22 is located above the polishing table 2. The rod 23 is threadedly matched with the thread groove 21 , and the top is connected to the bottom surface of the support plate 22 , the blocking mechanism 24 is fixed on the bottom of the support plate 22 and wrappe...

Embodiment 2

[0036] as attached Figure 6to attach Figure 8 Shown:

[0037] Wherein, the contact block d4 is provided with a movable groove e1, a rotating ring e2, a matching plate e3, and a stacking cavity e4, the movable groove e1 is recessed on the top of the contact block d4, and the rotating ring e2 is connected and installed inside the movable groove e1, The matching plate e3 is set on the inner wall of the movable groove e1, and is movably matched with the rotating ring e2. The accumulation chamber e4 is set at the inner bottom of the contact block d4 and communicates with the movable groove e1. The upper surface of the matching plate e3 is concave-convex The uneven surface can increase the friction between the matching plate e3 and the outer wall of the rotating ring e2, and evenly remove the debris on the outer wall of the rotating ring e2. There are three rotating rings e2, which is conducive to the continuous contact between the rotating ring e2 and the exhaust port s2 The in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com