Crusher for construction waste

A technology of construction waste and crusher, which is applied in the direction of separating solids from solids with airflow, solid separation, grain treatment, etc., can solve the problem of large land expropriation fees, garbage removal and transportation costs, construction funds, wood waste mixed with cement blocks and iron Nails, lime sand flying environment and other problems, to achieve the effect of improving recycling efficiency, improving sharpness, and improving crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

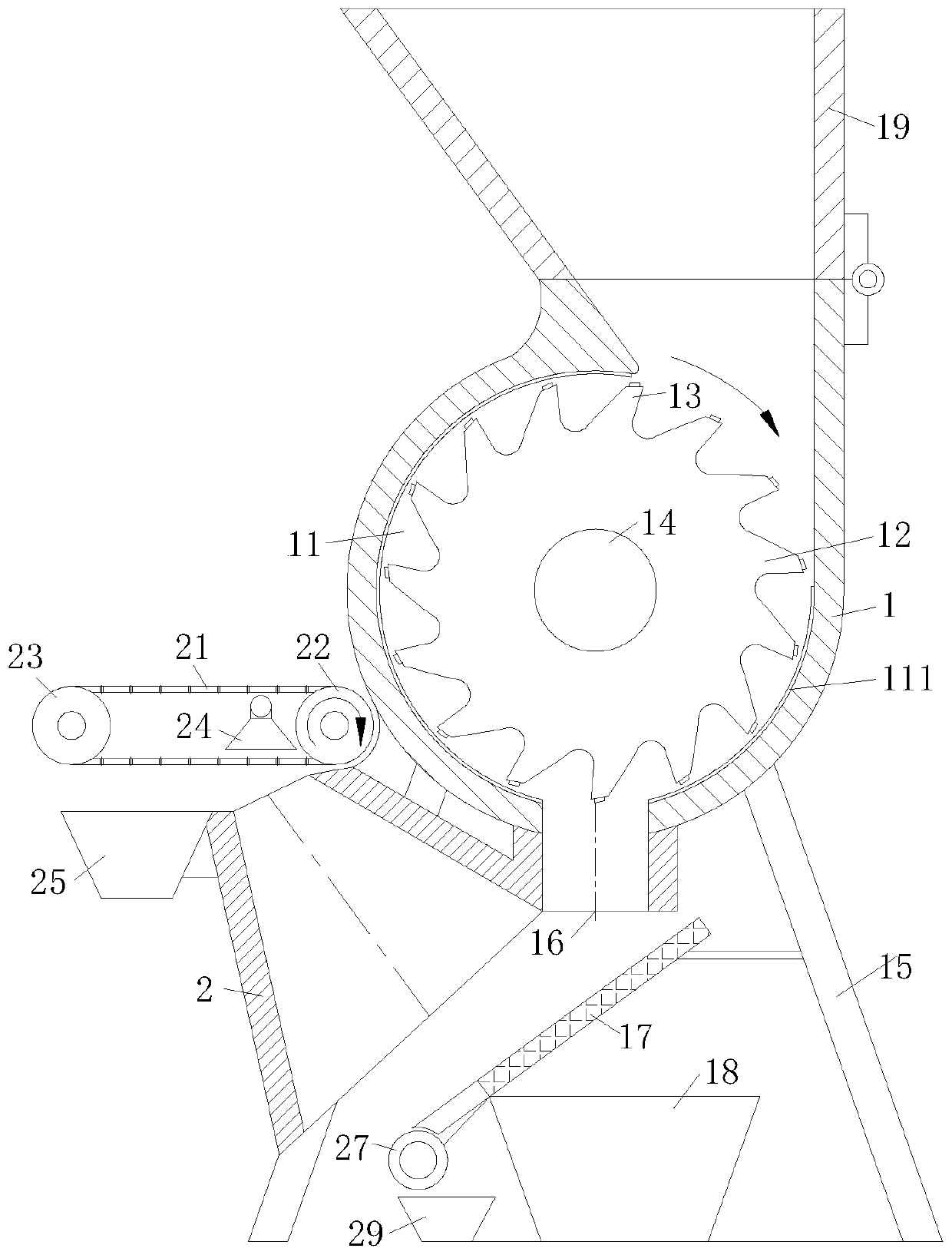

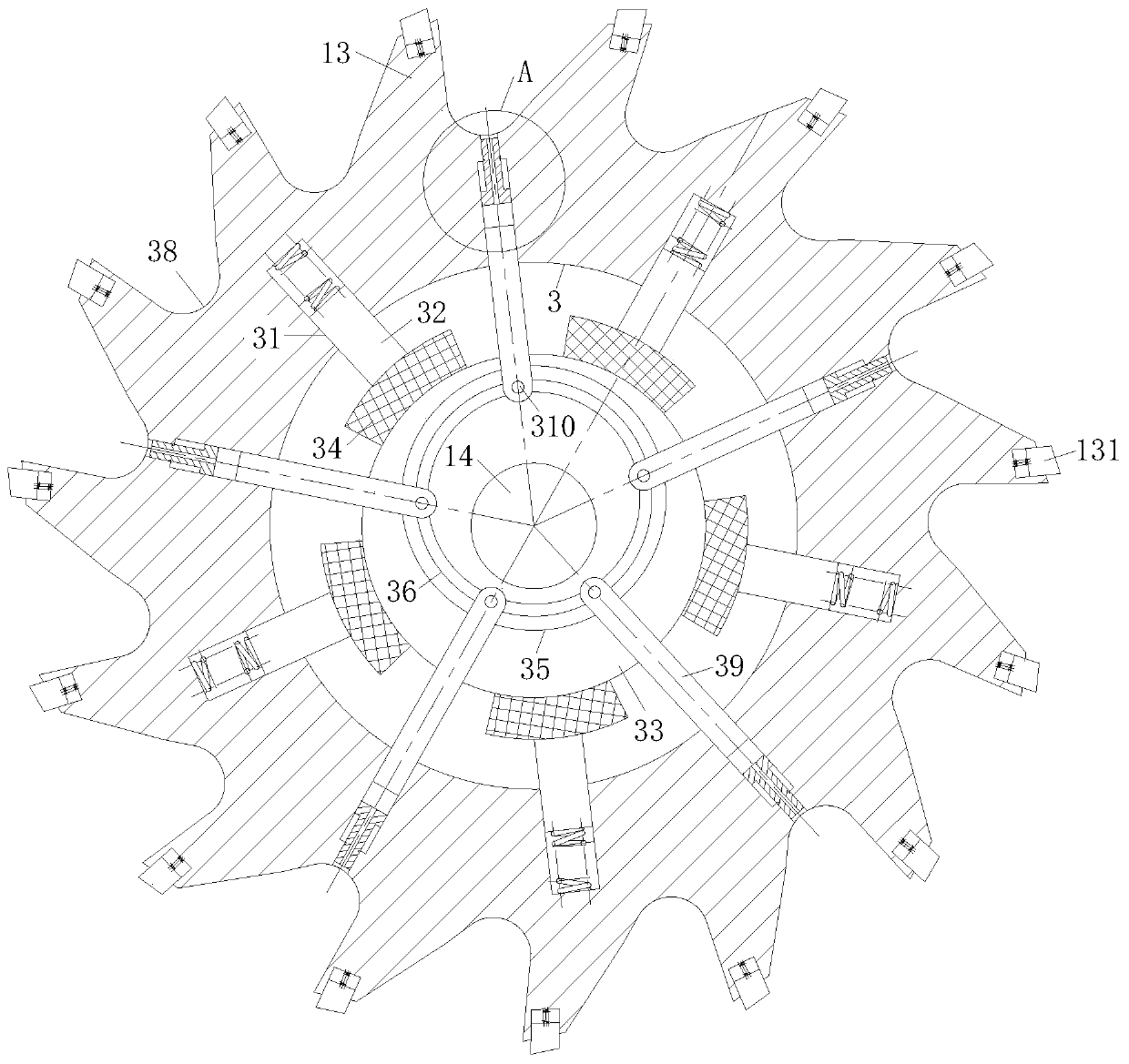

[0026] As an embodiment of the present invention, a funnel-shaped separation bucket 2 is provided on one side of the feeding hole 16, and the axis of the separation bucket 2 is perpendicular to the top surface of the screen 17; the top of the separation bucket 2 is provided with a conveyor belt 21, The conveyor belt 21 is tensioned and driven by the driving wheel 22 and the driven wheel 23, both of which are rotationally connected with the casing 1; the driving wheel 22 is driven by the No. 2 motor, and the No. 2 motor is connected to the power supply through the controller The conveyer belt 21 is made of air-permeable steel wire mesh, and the corresponding position of the middle part of the conveyer belt 21 and the top opening of the separation bucket 2 is provided with an air extraction funnel 24, and the air extraction funnel 24 is communicated with the air extractor, and the air extractor is connected by a controller Power supply; the exhaust port of the air extractor commu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com