Ceramic protective sleeve

A technology of protective sleeve and ceramic sleeve, which is applied in the direction of combustion method, lighting and heating equipment, ignition by electric spark, etc. It can solve the problems of difficult to guarantee the quality of batch ignition needles and unreliable connection, and achieve the effect of fast and reliable installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

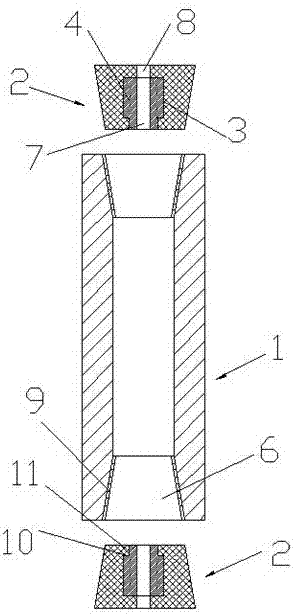

[0012] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

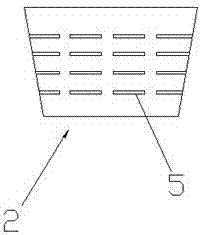

[0013] Such as figure 1 , figure 2 As shown, the present invention is a ceramic protective sleeve, including a ceramic sleeve 1 and two plugs 2, the plugs 2 are a circular truncated structure made of rubber, the inner end surface of the plug 2 is provided with a boring hole 3, The boring hole 3 is embedded with a ceramic cylinder 4, the end face of the ceramic cylinder 4 at the entrance of the boring hole 3 is flush with the inner end surface of the plug 2, and the outer wall of the plug 2 is provided with striped protrusions 5, so that The two ends of the inner wall of the ceramic sleeve 1 are provided with slope openings 6 , the slope openings 6 are match...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com