A method and device for controlling the head thickness of a hot-rolled coil

A control method and technology of hot-rolled coils, applied in rolling force/roll gap control, tail end control, metal rolling, etc., can solve problems such as unsatisfactory control effect of strip head thickness, and improve control accuracy, Improving the effect of technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

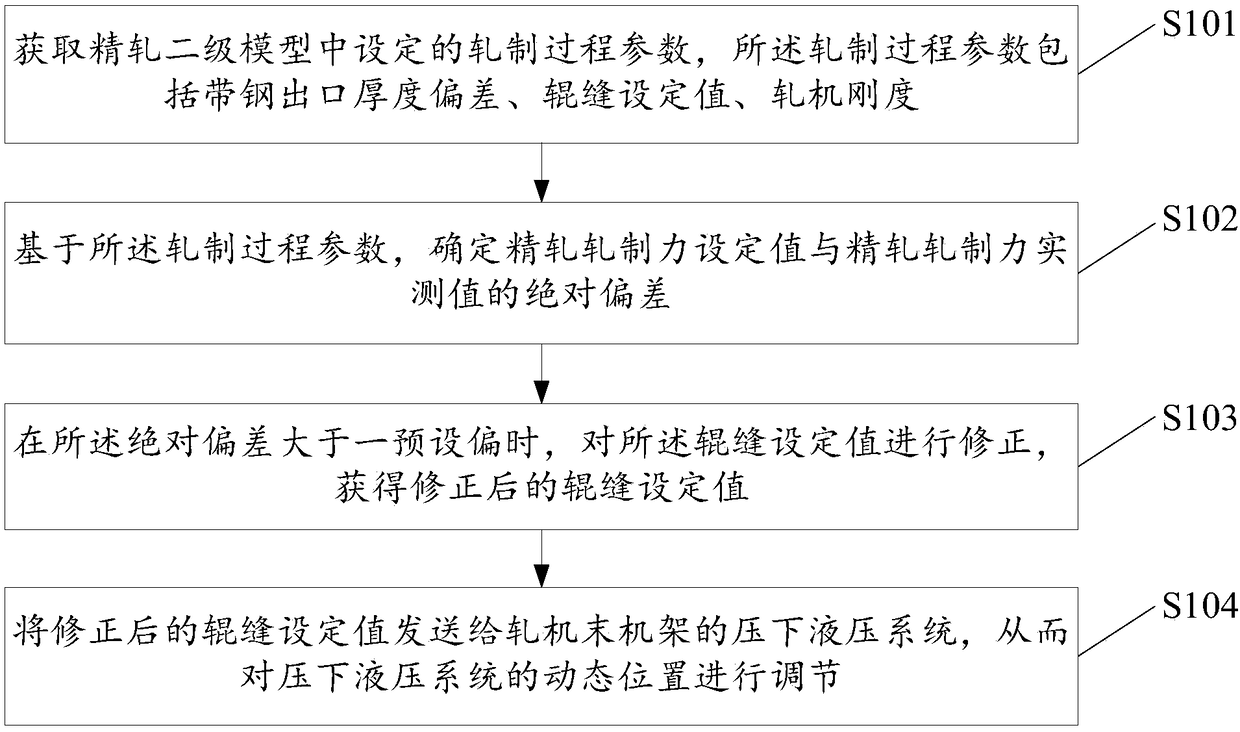

[0055] This embodiment provides a method for controlling the head thickness of hot-rolled coils, which is applied to the finishing rolling control system of a hot-rolled production line, such as figure 1 As shown, the method for controlling the head thickness of the hot-rolled coil includes:

[0056] Step S101: Acquiring the rolling process parameters set in the secondary model of finish rolling, the rolling process parameters including strip exit thickness deviation, roll gap setting value, and rolling mill stiffness.

[0057] In a specific implementation process, the secondary model of finish rolling includes: a calculation model for intermediate billet temperature, a calculation model for rolling force setting, a calculation model for roll gap setting, and a corresponding self-learning model.

[0058] In the specific implementation process, there is a control model for finish rolling (namely: the "secondary model" mentioned in the article), which will give the set values ...

Embodiment 2

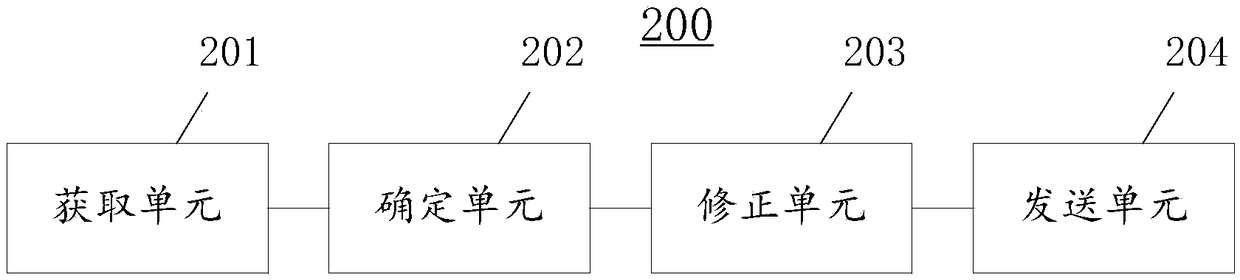

[0098] Based on the same inventive concept, this embodiment provides a control device 200 for the head thickness of hot-rolled coils, which is applied to the finishing rolling control system of a hot-rolled production line, such as figure 2 As shown, the control device 200 for the head thickness of the hot-rolled coil includes:

[0099] The obtaining unit 201 is used to obtain the rolling process parameters set in the secondary model of finishing rolling, the rolling process parameters including strip exit thickness deviation, roll gap setting value, and rolling mill stiffness;

[0100] A determination unit 202, configured to determine the absolute deviation between the set value of the finishing rolling force and the measured value of the finishing rolling force based on the rolling process parameters;

[0101] A correction unit 203, configured to correct the roll gap setting value when the absolute deviation is greater than a preset deviation, to obtain a corrected roll gap...

Embodiment 3

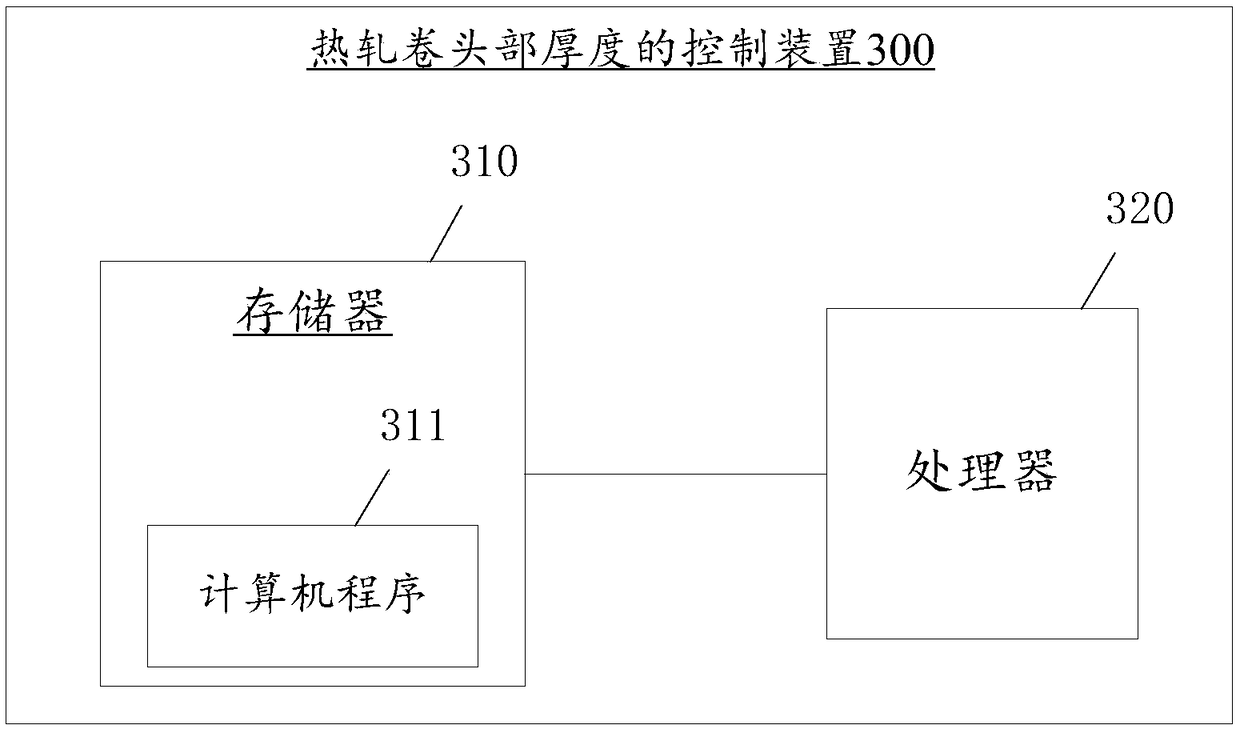

[0117] Based on the same inventive concept, this embodiment provides a control device 300 for the head thickness of hot-rolled coils, which is applied to the finishing rolling control system of a hot-rolled production line, such as image 3 As shown, the control device for the head thickness of the hot-rolled coil includes a memory 310, a processor 320, and a computer program 311 stored on the memory 310 and operable on the processor 320. When the processor 320 executes the computer program 311 Implement the following steps:

[0118] Obtain the rolling process parameters set in the finishing rolling secondary model, the rolling process parameters include strip exit thickness deviation, roll gap setting value, rolling mill stiffness; based on the rolling process parameters, determine the finishing rolling process parameters The absolute deviation between the force set value and the measured value of the finishing rolling force; when the absolute deviation is greater than a pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com