Hinge synchronization type telescopic protecting cover

A protective cover and synchronous technology, applied in the direction of maintenance and safety accessories, metal processing machinery parts, metal processing equipment, etc., can solve the problems of poor orientation, difficult design, and many protective layers, and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

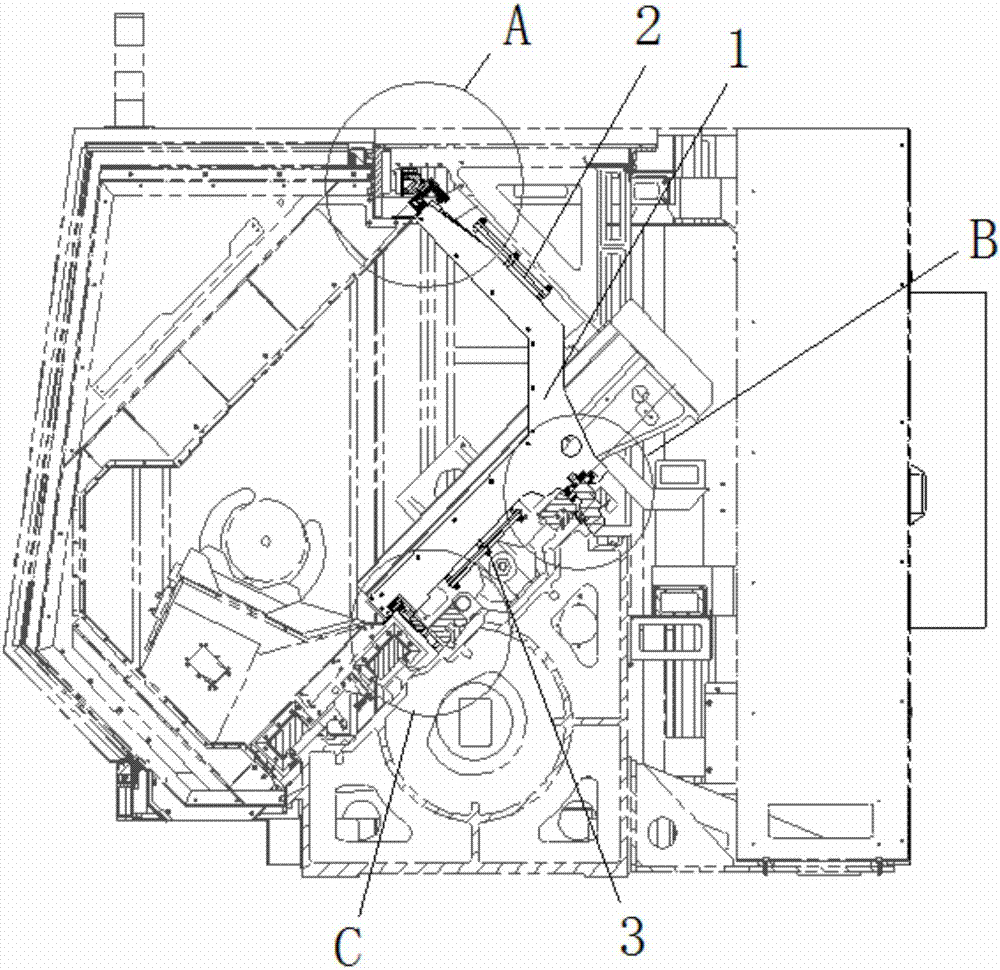

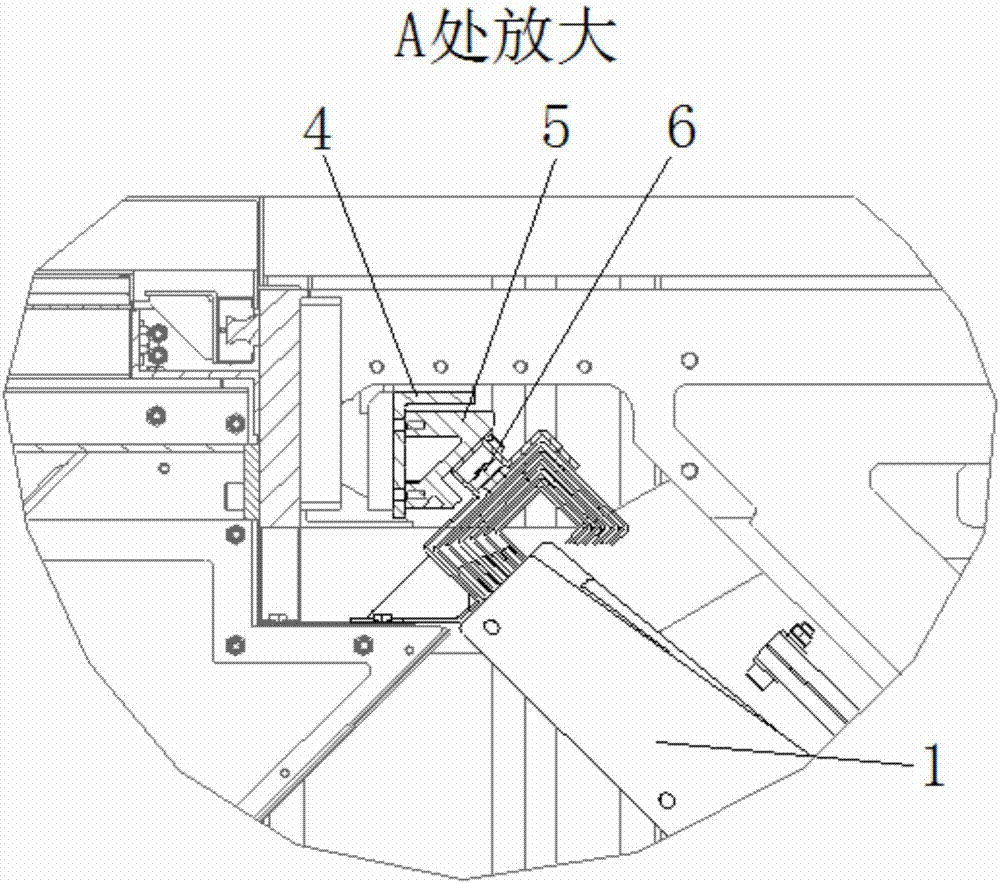

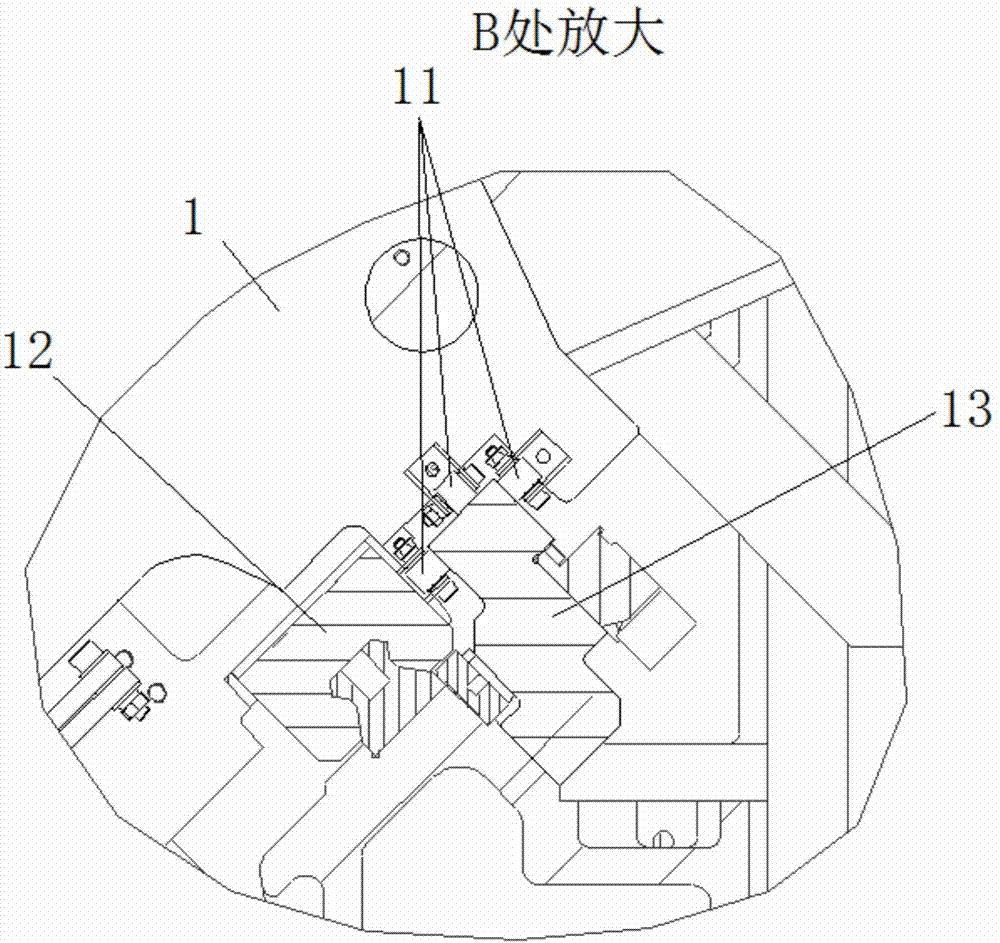

[0030] Such as Figure 1-9 As shown, the present invention comprises telescopic protective cover body 1, upper guide rail, middle guide rail 13 and lower guide rail 9, and described each guide rail is all installed on the machine tool main frame, as figure 1 As shown, the cross section of the telescopic protective cover body 1 is L-shaped, and when the present invention is installed on the machine tool host, the two straight sides of the telescopic protective cover body 1 are 45 degrees to the horizontal direction, and the The two ends of the upper and lower sides of the telescopic protective cover body 1 are respectively provided with an upper guide wheel 6 and a lower guide wheel 8. The upper guide wheel 6 walks along the upper guide rail, and the lower guide wheel 8 walks along the lower guide rail. The guide rail 9 travels, and the right-angled end at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com