A sea surface garbage cleaning device for marine environmental protection and its cleaning method

A technology for environmental protection and garbage cleaning, which is applied to the cleaning of open water surfaces, construction, water conservancy projects, etc., can solve problems such as poor safety, time-consuming and labor-intensive salvage of ocean surface garbage, and prevent slipping or falling off, improve efficiency and stability, and improve The effect of the power drive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

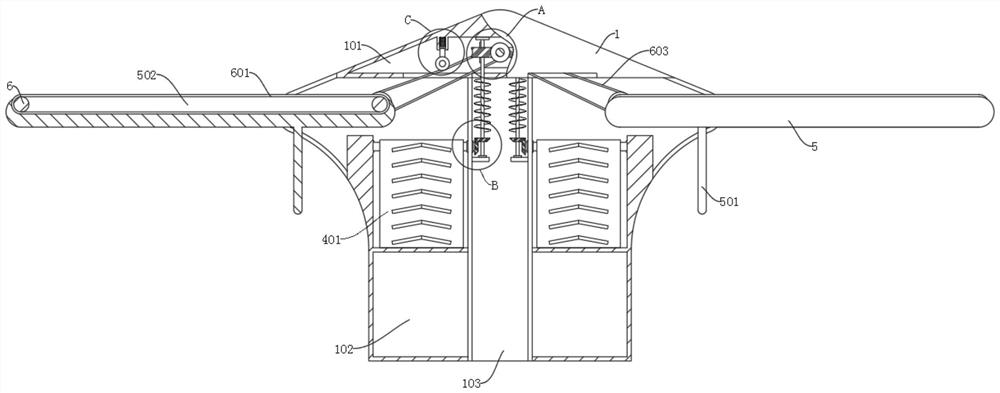

[0037] refer to figure 1 , figure 2 , Figure 4 and Image 6 , a sea surface garbage cleaning device for marine environmental protection, including a main body 1, the main body 1 is mostly hollow material, to ensure that it can float on the sea surface, and has a certain load-bearing capacity, the main body 1 is provided with a working cavity 101, a collection In the bin 102 and the power channel 103, two sets of collecting plates 5 are rotated in the middle of the main body 1. The two sets of collecting plates 5 are symmetrically arranged on both sides of the main body 1 and extend out of the main body 1. One side of the collecting plate 5 is provided with a turning plate 501 , the diverting plate 501 protrudes downward, and contacts the water body before the collecting plate 5. When the collecting plate 5 is inclined synchronously, the diverting plate 501 can promote the change of the traveling direction of the main body 1, so as to better collect the garbage on the vast ...

Embodiment 2

[0039] refer to figure 1 , figure 2 and Image 6 , which is basically the same as Embodiment 1, but on this basis, the diversion part is refined, including the second rotating shaft 6 and the first conveyor belt 601 sleeved on the second rotating shaft 6, and the first transmission belt 601 is submerged by seawater for about three The second rotating shaft 6 is rotatably arranged on the collecting plate 5, and the collecting plate 5 is provided with a conveying slot 502, and the first conveying belt 601 is arranged on the In the conveying slot 502, the height of the first conveying belt 601 is about half of that of the collecting plate 5, and during the forward movement of the main body 1, the first conveying belt 601 will continuously rotate into the main body 1, so as to ensure that the collecting plate 5 intercepts The garbage can be sent into the main body 1 in time to prevent the garbage accumulation from being beaten by the waves and cross the collection board 5, which ...

Embodiment 3

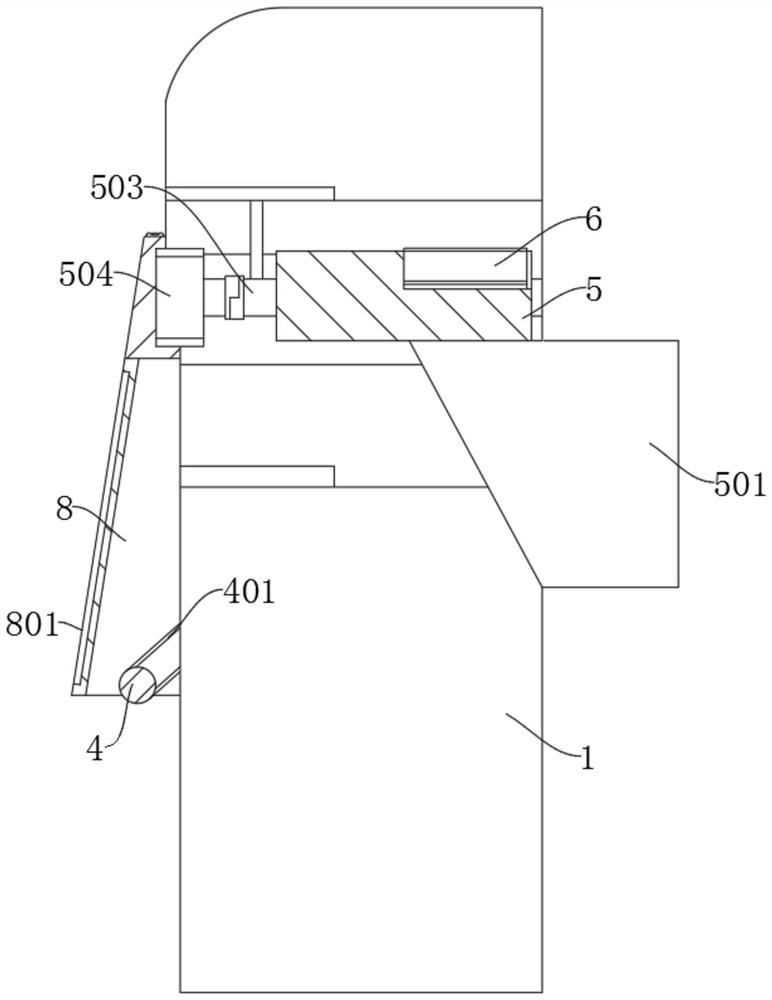

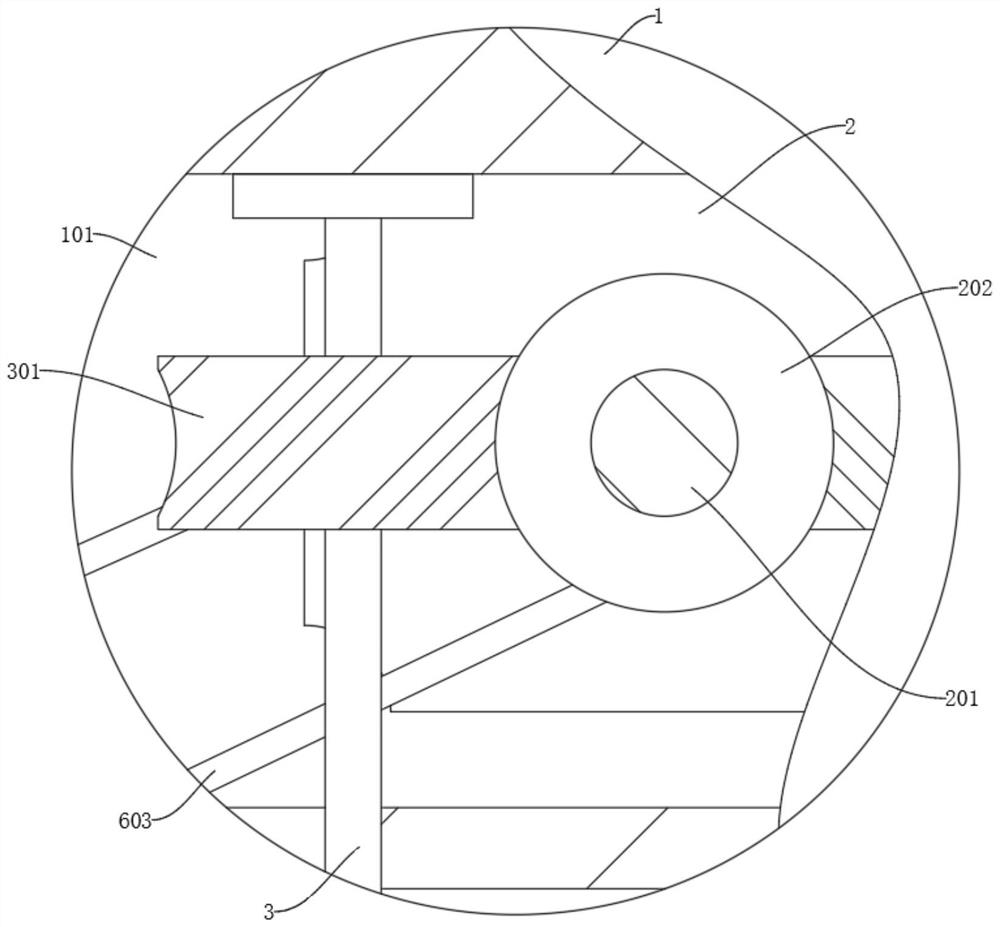

[0041] refer to figure 1 , image 3 ,and Figure 5 , is basically the same as Embodiment 1. On this basis, a first motor 2 is arranged in the working chamber 101, a drive shaft 201 is arranged at the output end of the first motor 2, a first pulley is arranged on the drive shaft 201, and a second pulley is arranged on the drive shaft 201. The rotating shaft 6 is provided with a second pulley 602, the first pulley is rotatably connected to the second pulley 602 through a belt 603, and a tensioning part matched with the belt 603 is arranged in the working chamber 101, and the tensioning part can effectively ensure the collection During the turning process of the plate 5, the effective transmission of the belt 603 prevents the belt 603 from slipping or falling off, and ensures that the collected garbage can be effectively guided. A telescopic column 701 is provided, and a tensioning wheel 702 is rotatably arranged on the telescopic column 701. The tensioning wheel 702 is in cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com