Rubber injection mold

A technology of injection molding and rubber, which is applied to other household appliances, household appliances, household components, etc., can solve the problems of cumbersome procedures, low production capacity, and high production costs, and achieve reduction of equipment, precise control of material volume, reduction of material waste and labor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

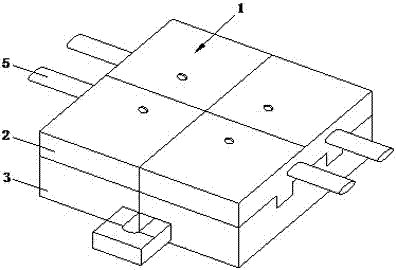

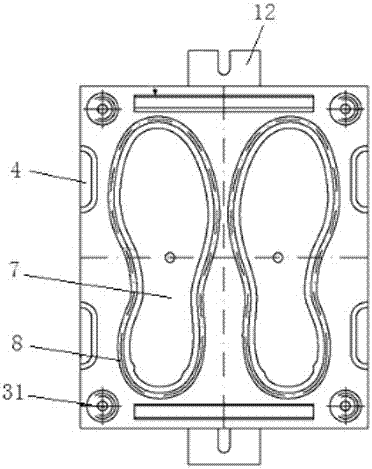

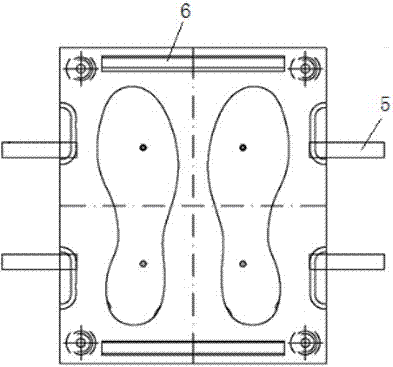

[0024] see Figure 1-5 , in an embodiment of the present invention, a rubber injection mold includes two demoulding molds 1, the second demoulding mold 1 is composed of an upper mold 2 and a bottom mold 3, and the upper mold 2 and the bottom mold 3 are movably connected by a guide post 31 , the guide post 31 is welded on the bottom mold 3, and the upper surface of the upper mold 2 is also provided with a tapered feeding hole, which is connected with the finished product area 7, so as to realize the color matching production of single color or double color, and the upper mold 2 and the two ends of the bottom mold 3 are also provided with side rails 4, and the upper mold handle 5 is fixedly installed in the side rail 4 of the upper mold 2, one end of the upper mold handle 5 is fixedly connected with the inner wall of the side rail 4, and the other end extends Out of the upper mold 2, the lower surface of the upper mold 2 and the upper surface of the bottom mold 3 are respectivel...

Embodiment example 2

[0026] see Figure 6-7 , in an embodiment of the present invention, a rubber injection mold includes three demoulding molds 13, the three demoulding molds 13 are composed of an upper mold 2, a bottom mold 3 and a middle plate 14, and the middle plate 14 is located between the upper mold 2 and the bottom mold 3 between the upper mold 2 and the bottom mold 3 through guide pillars 31, and the guide pillars 31 are welded on the bottom mold 3; A patrix handle 5 is fixedly installed in the side rail 4 of the patrix, and one end of the patrix handle 5 is fixedly connected with the inner wall of the side rail 4, and the other end extends out of the outside of the patrix 2, and the lower surface of the patrix 2 and the upper surface of the bottom mould 3 The front and rear shelves 5 are fixedly installed on the surface respectively, and the front and rear shelves 5 match each other. The front and rear shelves 5 prevent the material from overflowing after being squeezed. The lower surfa...

Embodiment example 3

[0028] see Figure 8-11 , in the embodiment of the present invention, a kind of rubber injection mold comprises four demoulding molds 16, and four demoulding molds 16 are made up of upper mold 2, bottom mold 3, middle plate 14 and middle frame 17, middle plate 14 and middle frame 17 Fitting connection, and located between the upper mold 2 and the bottom mold 3, the upper mold 2 and the bottom mold 3 are flexibly connected through the guide post 31, the guide post 31 is welded on the bottom mold 3, the upper mold 2 and the bottom mold 3 Side rails 4 are also provided at both ends, and upper mold handles 5 are fixedly installed inside the side rails 4 of the upper mold 2. One end of the upper mold handle 5 is fixedly connected with the inner wall of the side rails 4, and the other end extends out of the upper mold 2. , the lower surface of the upper mold 2 and the upper surface of the bottom mold 3 are respectively fixedly equipped with front and rear shelves 5, and the front an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com