Tea staged breaking device

A technology of graded crushing and crushing devices, which is applied in packaging, transportation, packaging, containers, etc. It can solve the problems of affecting the tea brewing rate, poor tea taste purity, and insufficient tea crushing, and achieve the effect of strengthening the sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

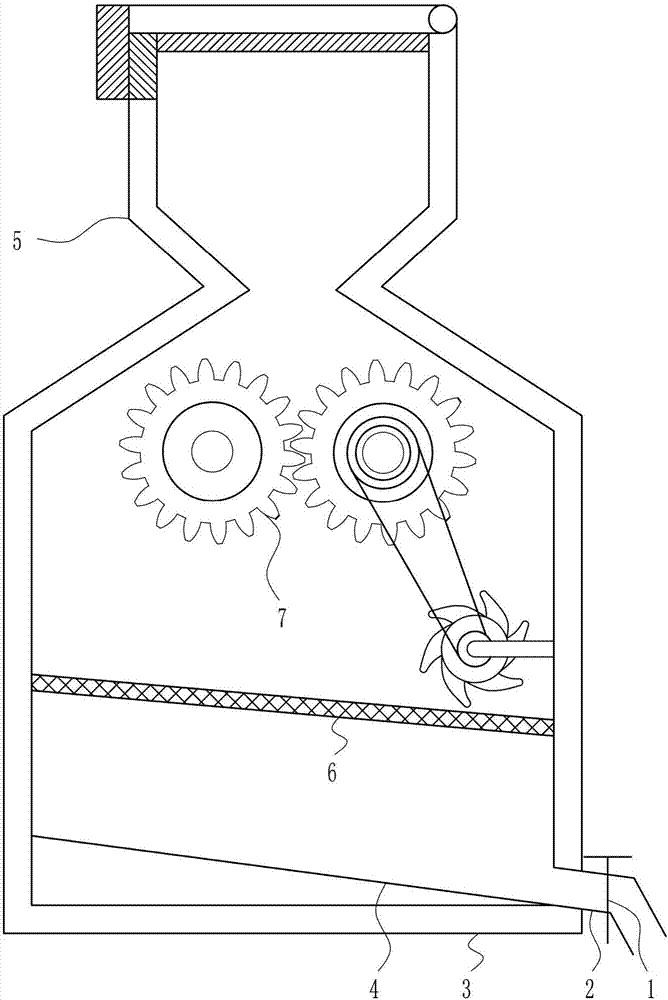

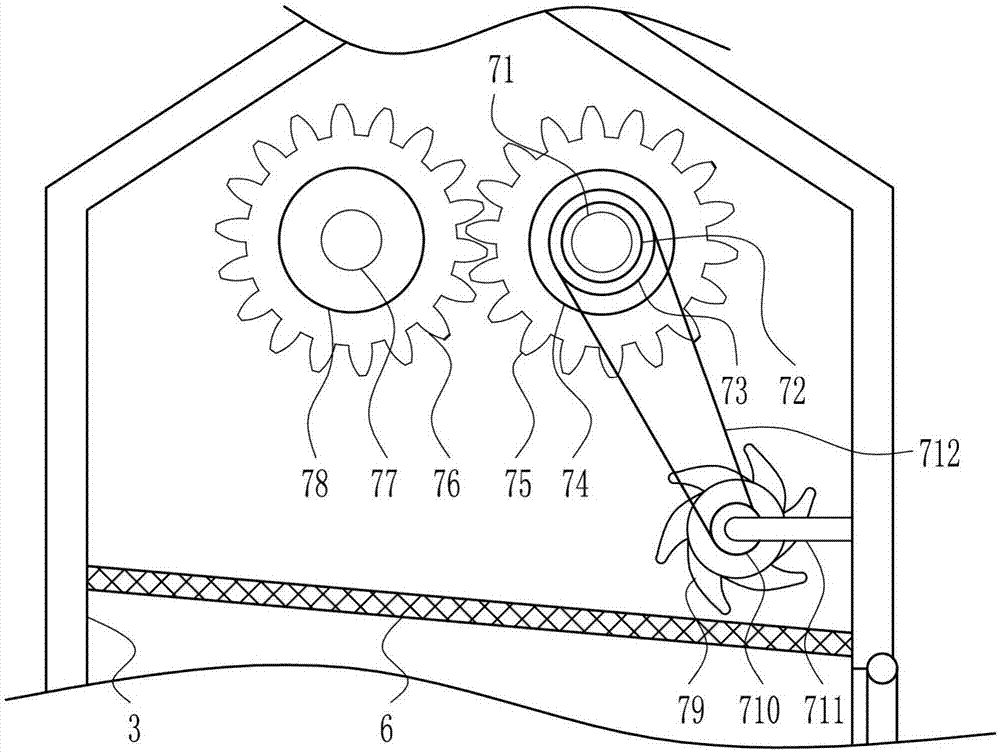

[0031] A tea classification and crushing device, such as Figure 1-5 As shown, it includes valve 1, discharge hopper 2, processing box 3, inclined plate 4, feeding device 5, screen plate 6 and crushing device 7. The lower part of the right side of the processing box 3 is connected with a discharge hopper 2, and the discharge hopper 2 is provided with There is a valve 1, the inner bottom of the treatment box 3 is provided with a sloping plate 4, the middle and lower part of the treatment box 3 is connected with a mesh plate 6, the mesh plate 6 is arranged above the discharge hopper 2, and the upper part of the inner rear wall of the treatment box 3 is provided with a crushing device 7 , the top of the processing box 3 is connected with a feeding device 5 .

Embodiment 2

[0033] A tea classification and crushing device, such as Figure 1-5 As shown, it includes valve 1, discharge hopper 2, processing box 3, inclined plate 4, feeding device 5, screen plate 6 and crushing device 7. The lower part of the right side of processing box 3 is connected with a discharge hopper 2, and the discharge hopper 2 is provided with There is a valve 1, the inner bottom of the treatment box 3 is provided with a sloping plate 4, the middle and lower part of the treatment box 3 is connected with a mesh plate 6, the mesh plate 6 is arranged above the discharge hopper 2, and the upper part of the inner rear wall of the treatment box 3 is provided with a crushing device 7 , the top of the processing box 3 is connected with a feeding device 5 .

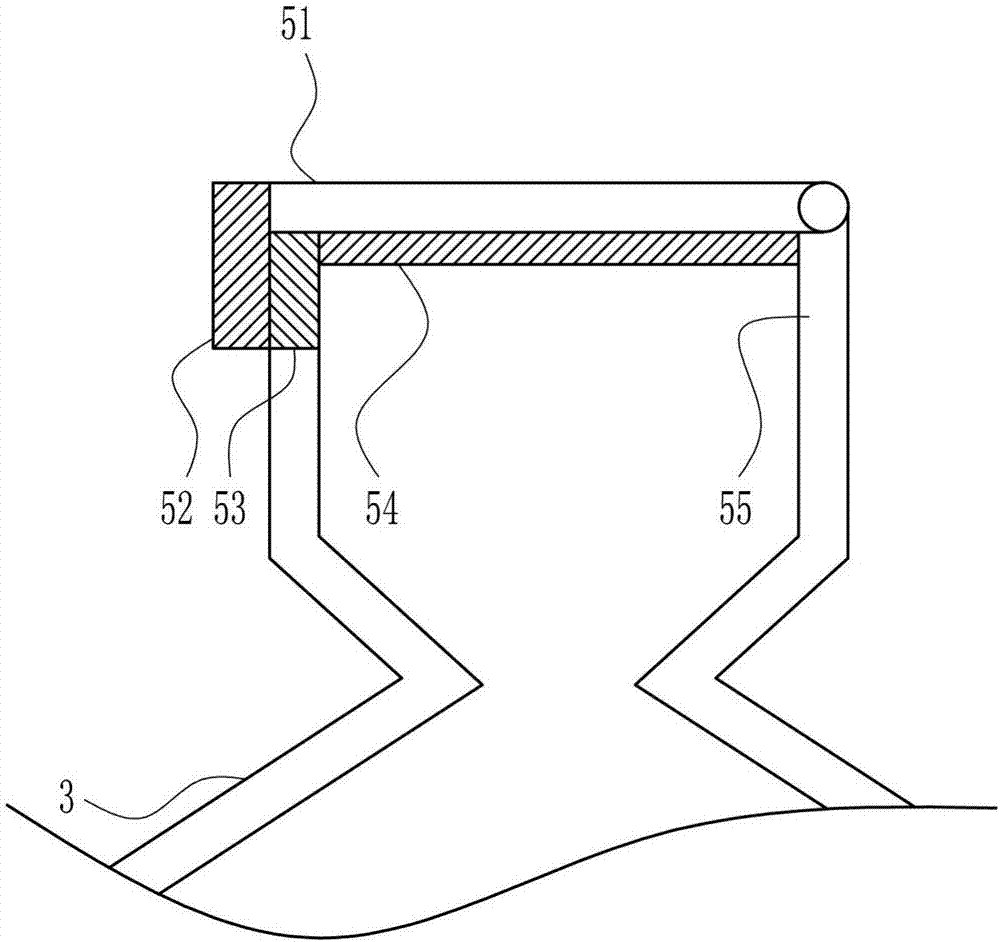

[0034] The feeding device 5 includes a cover plate 51, a first magnet block 52, a second magnet block 53, a rubber pad 54 and a feeding hopper 55. The upper end of the processing box 3 is connected with a feeding hopper 55, and...

Embodiment 3

[0036]A tea grading and crushing device, such as Figure 1-5 As shown, it includes a valve 1, a discharge hopper 2, a processing box 3, an inclined plate 4, a feeding device 5, a mesh plate 6 and a crushing device 7, and the lower part of the right side of the processing box 3 is connected with a discharge hopper 2, and the There is a valve 1, the inner bottom of the processing box 3 is provided with a sloping plate 4, the middle and lower part of the processing box 3 is connected with a mesh plate 6, the mesh plate 6 is arranged above the discharge hopper 2, and the upper part of the inner rear wall of the processing box 3 is provided with a crushing device 7 , the top of the treatment box 3 is connected with a feeding device 5 .

[0037] The feeding device 5 includes a cover plate 51, a first magnet block 52, a second magnet block 53, a rubber pad 54 and a feed hopper 55, the upper end of the processing box 3 is connected with a feed hopper 55, and the upper end of the feed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com