Bridge construction device

A bridge construction and equipment technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of falling apart, hidden safety hazards, complex design structures, etc., and achieve reduced manufacturing costs, safe and reliable work, and safe clamping reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

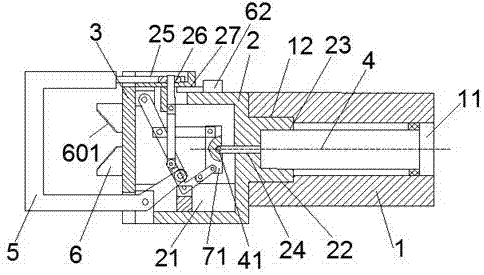

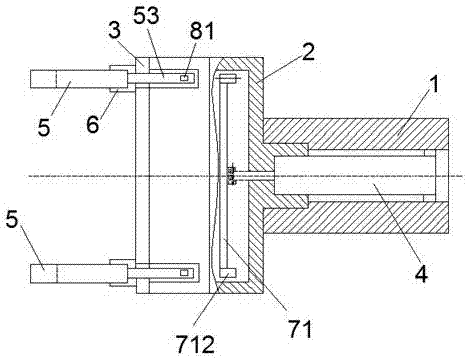

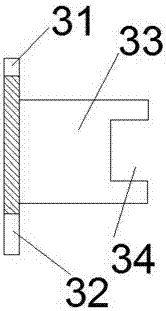

[0030] like Figure 1-Figure 11 As shown, a kind of bridge construction equipment of the present invention includes an engaging head 1 connected with a transport vehicle, and a second hollow cavity 21 fixed on the left end of the engaging head 1 and provided with a port to the left. There is an elongated groove 25 and the base frame 2 of the first through cavity 27 is arranged on the right side of the second cavity 21 below the elongated groove 25, and the base frame 2 in the middle of the elongated groove 25 is provided with The second through cavity 26 in the up and down direction, and a cover plate 3 that is fixedly installed on the left end of the base frame 2 and penetrates into the second hollow cavity 21 to the right, and two sets of linkage mechanisms, and a driving machine 4 , and two clamping claws 5, and an iron absorbing device installed on the upper surface of the base frame 2 on the right side of the first through cavity 27, and two fixing parts 6 fixed on the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com