Thread tension mechanism for hosiery machine

A hosiery machine and chuck technology, applied in textiles and papermaking, weft knitting, knitting, etc., can solve the problems of small applicability and inability to adjust the clamping strength of the device, and achieve the effect of wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

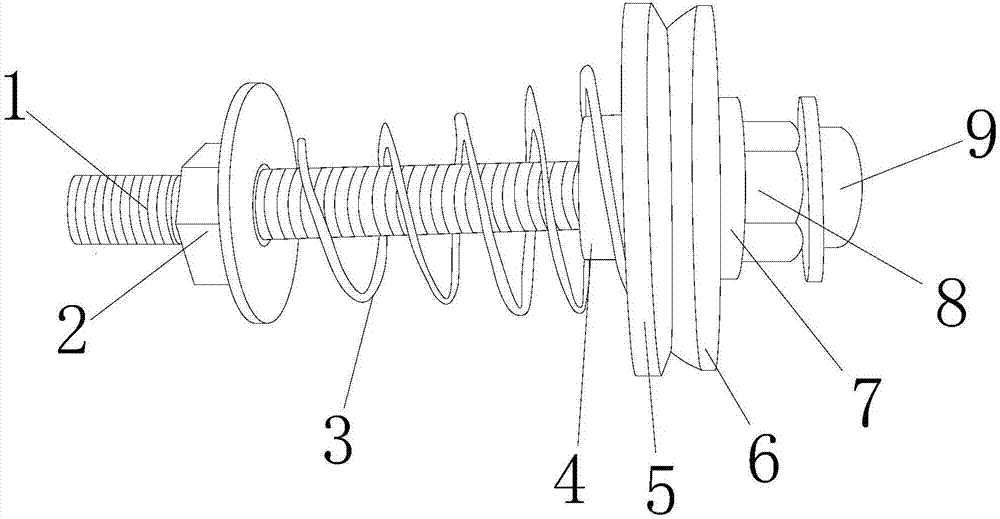

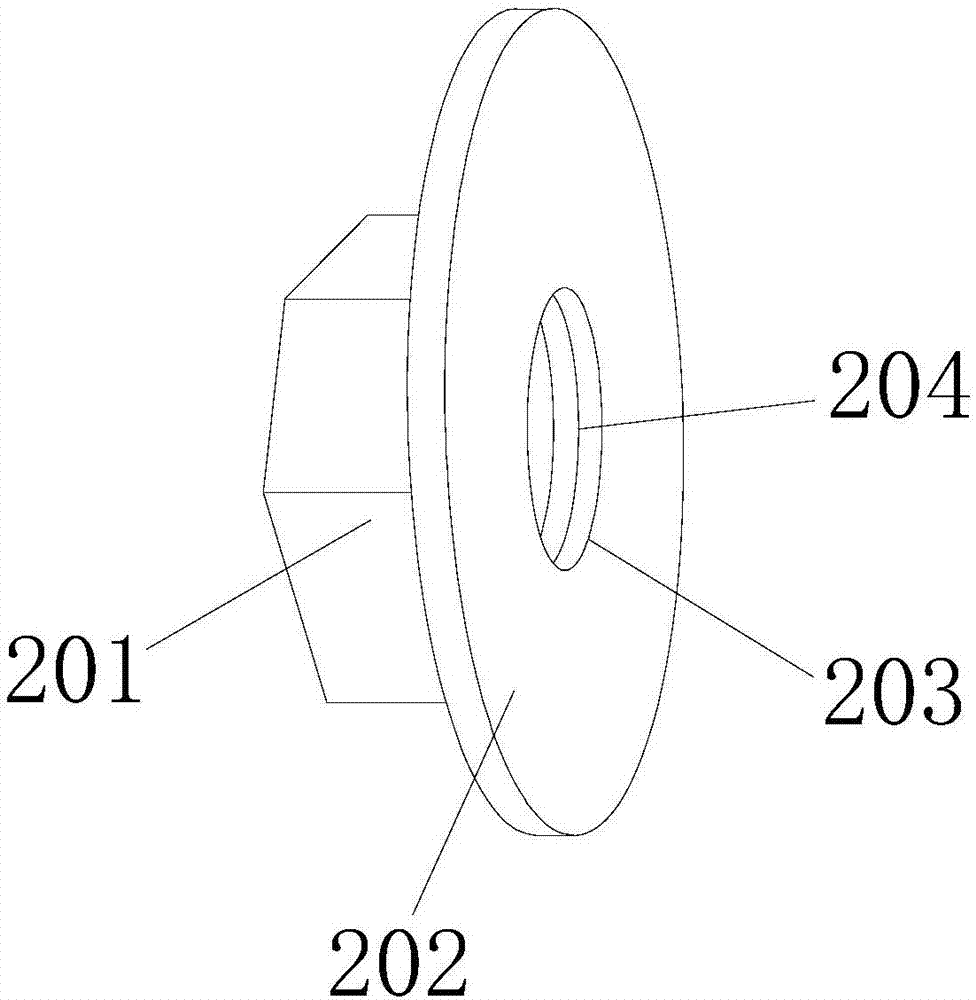

[0018] see Figure 1-Figure 2 , the present invention provides a hosiery machine thread clamping device: its structure includes a threaded rod 1, an adjustment knob 2, a spring 3, a lower sleeve 4, a lower chuck 5, an upper chuck 6, an upper sleeve 7, and a hex nut 8 , nut cap 9, the threaded rod 1 runs through the adjusting knob 2 and is threadedly connected with the lower socket 4, the threaded rod 1 runs through the upper socket 7 and is threadedly connected with the hex nut 8, and the inside of the spring 3 is provided with a threaded rod 1. One end of the spring 3 is connected with the adjusting knob 2 and has clearance fit, and the other end of the spring 3 is connected with the lower socket 4, and the lower socket 4 is arranged on the left ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap