High-precision greige cloth burr trimming equipment

A kind of trimming equipment and high-precision technology, applied in the direction of seam trimming, etc., can solve the problems of uneven trimming edge, low efficiency, waste of resources, etc., and achieve the effect of reasonable structural design optimization, accurate positioning, and improved stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

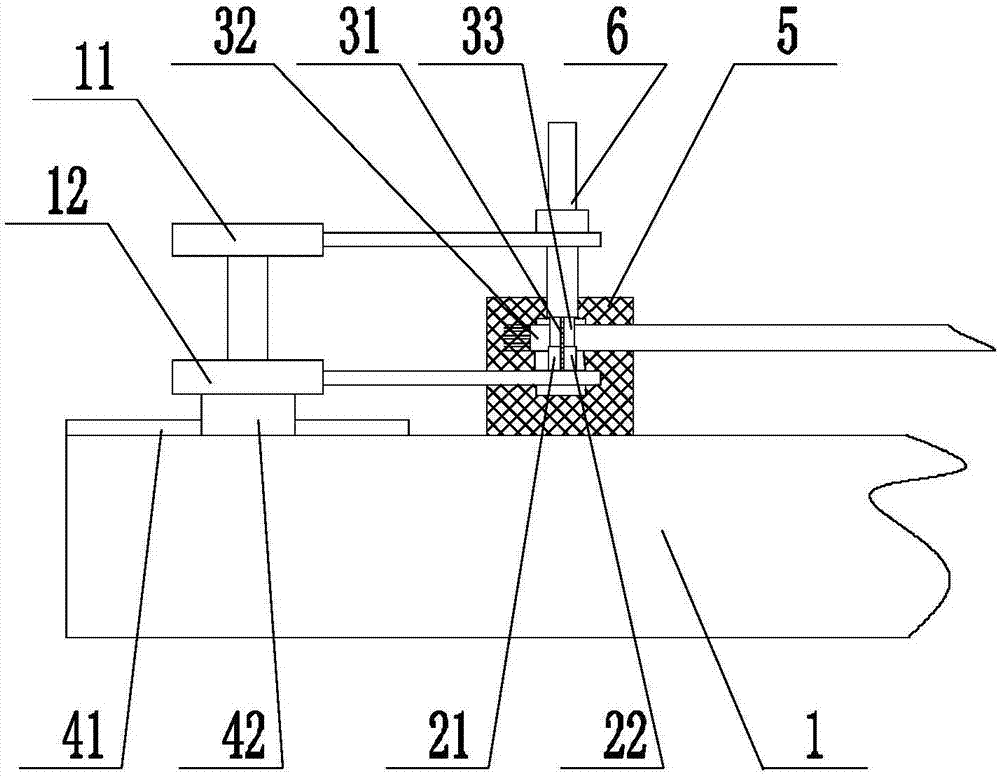

[0015] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a high-precision gray cloth trimming device proposed by the present invention.

[0016] refer to figure 1 , a kind of high-precision greige trimming equipment proposed by the present invention includes: a shearing mechanism, a positioning support mechanism, and a support table 1;

[0017] The support platform 1 is provided with a first mounting frame 11 and a second mounting frame 12, and the first mounting frame 11 is located above the second mounting frame 12;

[0018] The positioning support mechanism includes a first support member 21 and a second support member 22, the first support member 21 and the second support member 22 are located on the second mounting frame 12 and arranged at intervals, between the first support member 21 and the second support member 22 A blade receiving groove is formed between them;

[0019] The shearing mechanism is located above the positioning support mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com