Fast-algorithm-based multi-point on-site dynamic balancing method

An on-site dynamic balance and fast algorithm technology, which is applied in static/dynamic balance testing, complex mathematical operations, testing of machine/structural components, etc., can solve problems such as rotor system bending, single rotor structure, and long time-consuming, etc., to achieve Improve efficiency, measure a single element, and save production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

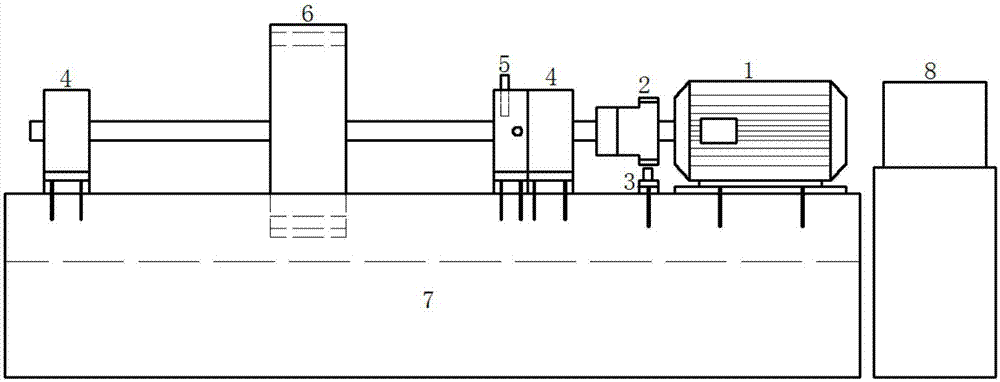

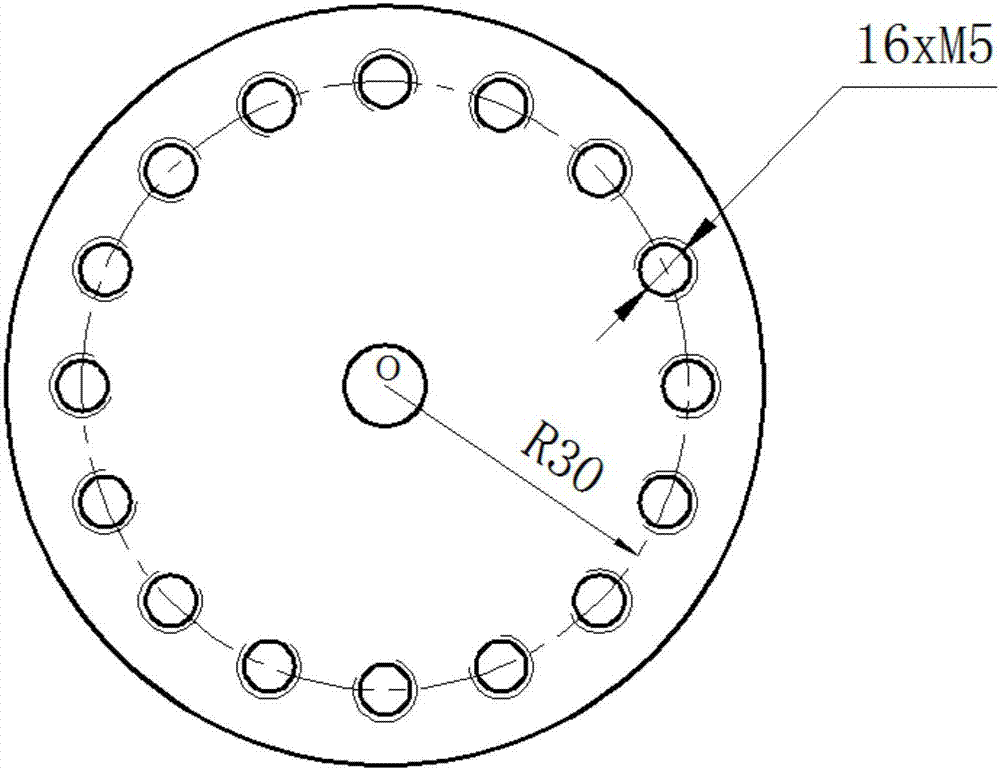

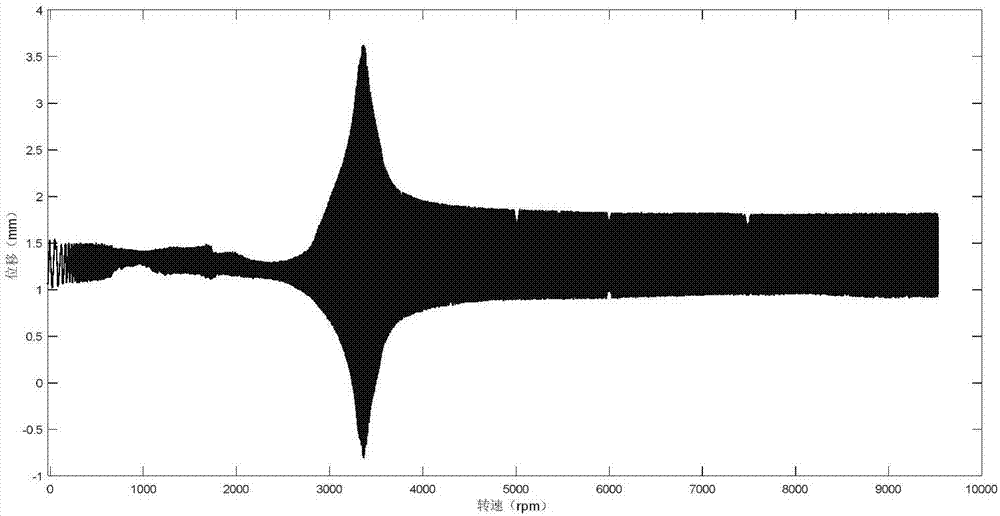

[0044] The invention discloses a multi-point on-site dynamic balancing method based on a fast algorithm. A geometric algorithm for setting multi-point dynamic unbalanced quantities in a fast algorithm program belongs to the field of rotor systems of rotating machinery. This method realizes on-site dynamic balance through calculation based on a fast algorithm by selecting a suitable rotor balance surface and performing simple measurement. The present invention includes the following processes: firstly, measure the vibration amplitude in the speed-up of the rotor system and the working speed, roughly obtain the unbalance amount, and estimate the weight of the test weight; secondly, divide the balance surface N (N≥3) into equal parts, and load the test weight The mass block and its vibration amount are measured; finally, each vibration amount is input into the fast algorithm data processing program, and the counterweight mass and "light point" position are directly obtained, loade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com