Construction method of drainage pipeline

A construction method and drainage pipeline technology, applied in the field of pipelines, can solve problems such as easy bending of formwork, and achieve the effect of enhancing the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

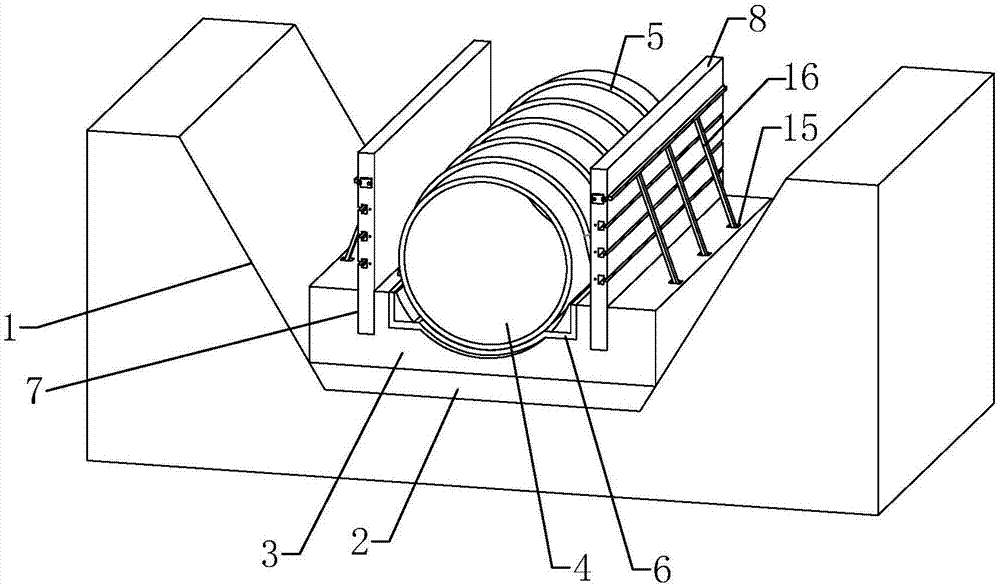

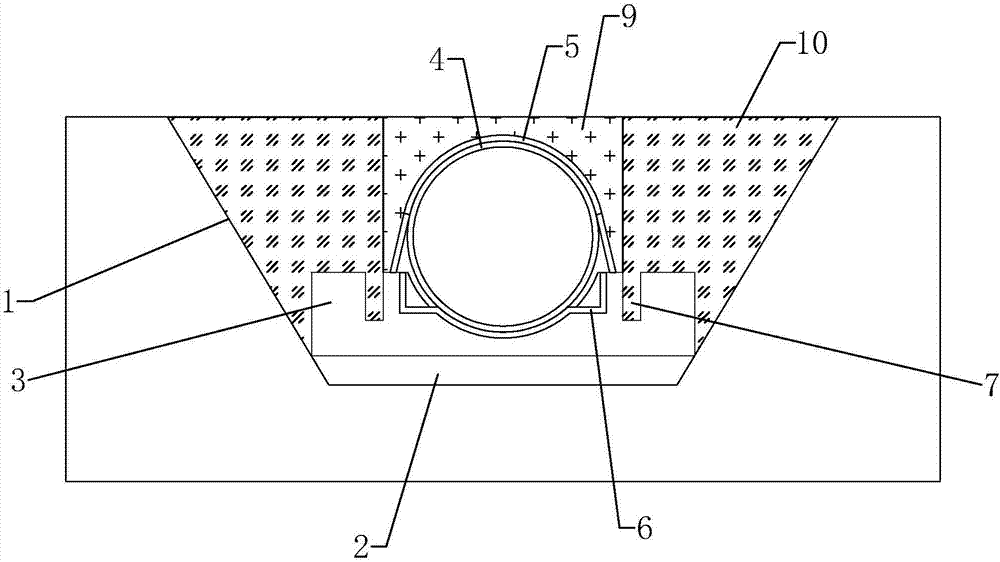

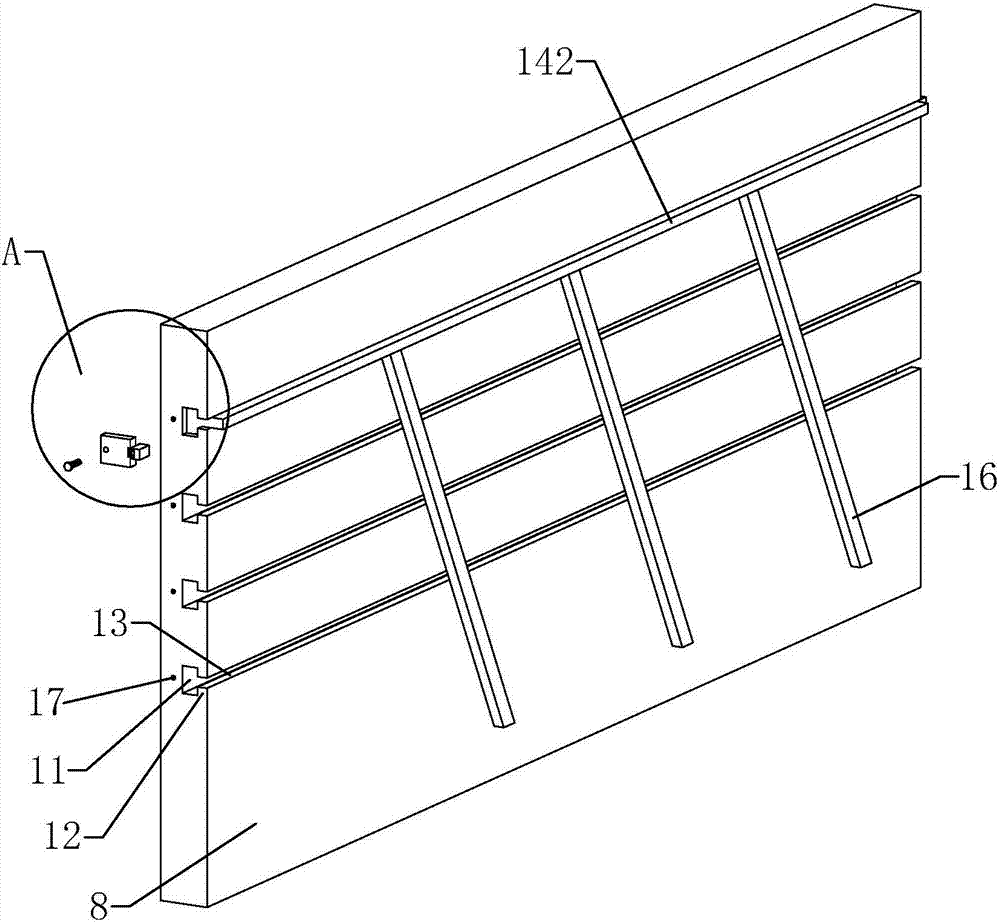

[0037] refer to figure 1 with 2 , a construction method for a drainage pipeline, comprising the steps of:

[0038] Step 1: Construction preparation: According to the design drawings, process the construction site, draw the construction outline, determine the elevation and position of the benchmarking point, prefabricate the pipeline frame, and place construction materials, machinery and personnel in place;

[0039] Step 2: Excavation of pipe trench 1: Calculate and determine the excavation width according to the designed trench bottom width, excavation depth and grading slope, and use a backhoe excavator to excavate backwards, and proceed in the direction of the slope of the pipeline against the current flow;

[0040] Step 3: Construction of flat foundation and cement solidified layer 2: After the excavation of the pipe groove 1 is completed, the elevation of the pipe bottom is measured, and the bottom soil is compacted, and then the ready-mixed lightweight concrete is used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com