Curing device for resin composite material, curing method, and molded resin article

A technology of resin composite material and curing device, which is applied in the direction of nanotechnology, nanotechnology, nanomedicine, etc., can solve the problems of inability to obtain curing reaction and inability to obtain strength, and achieve simplification and energy saving, low manufacturing cost, The effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

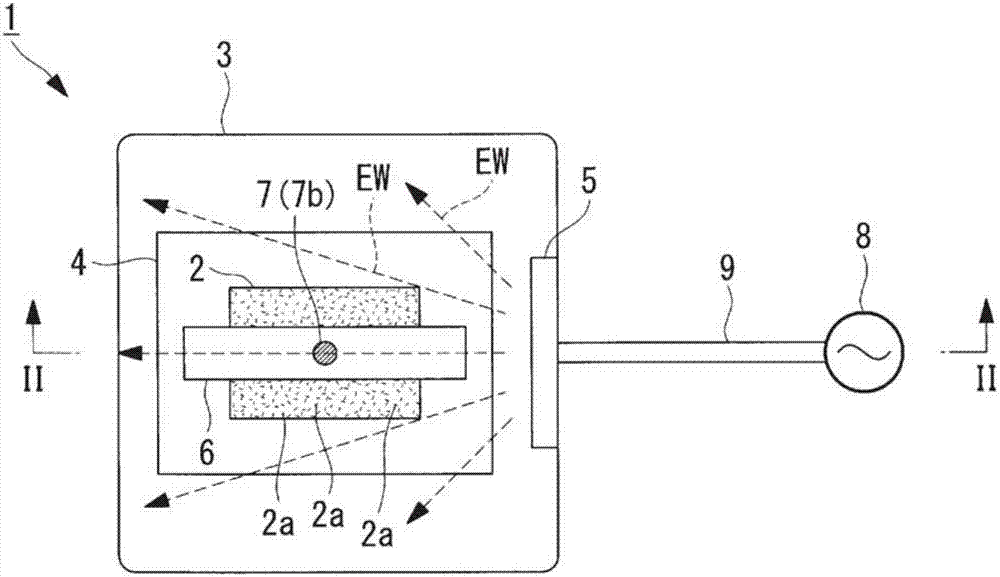

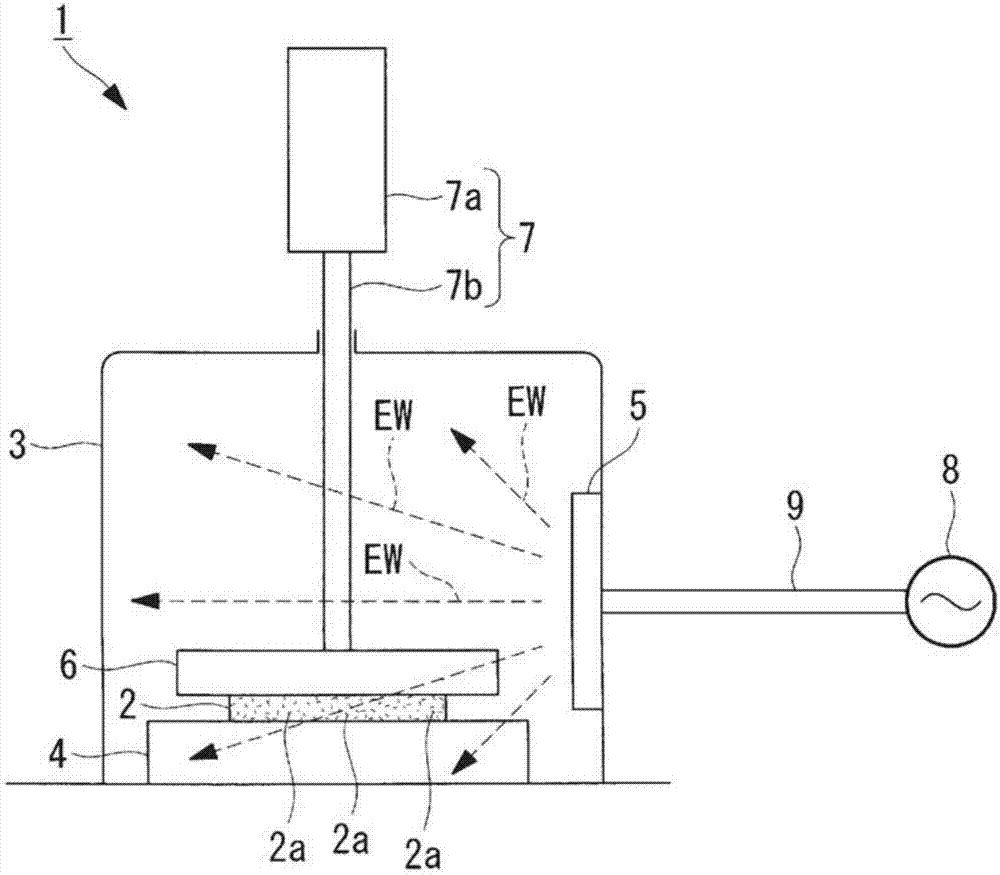

[0062] figure 1 It is a plan view showing the curing device according to the first embodiment of the present invention, figure 2 based on figure 1 The vertical cross-sectional view of the curing device viewed from the direction II-II.

[0063] This curing device 1 is, for example, a device that heats and cures an uncured prepreg 2 (resin composite material) while pressurizing it in the thickness direction. As we all know, the prepreg 2 is an intermediate molding material that is semi-integrated with a thermosetting or thermoplastic matrix resin and can be deformed at room temperature by laminating or impregnating a fibrous reinforcement such as carbon fiber or glass fiber with a thermosetting or thermoplastic matrix resin.

[0064] The curing device 1 is configured, for example, to include a box-shaped cavity 3, a flat molding table 4 at the bottom of the cavity 3, an electromagnetic wave irradiation unit 5 (environment setting unit) provided on the side inner surface of th...

no. 2 Embodiment approach

[0090] Figure 4 It is a plan view showing the curing device according to the second embodiment of the present invention.

[0091] The curing device 11 is the same as the curing device 1 of the first embodiment, and heats and cures the uncured prepreg 2 (resin composite material) added with the metal nanomaterial 2a in its thickness direction while applying heat.

[0092] The curing device 11 is configured to include a flat molding table 12 , a pair of electrodes 13A, 13B (environment setting unit) facing each other across the prepreg 2 placed on the molding table 12 , a plurality of pressurizing bodies 14 , High-frequency power supply 15 and coaxial cables 16A, 16B.

[0093] The curing device 11 forms a physical environment that increases the molecular motion of the metal nanomaterial 2 a contained in the matrix resin of the prepreg 2 by applying an electric field EF between the electrodes 13A and 13B. The electrodes 13A and 13B form an electric field EF by a high-frequency...

no. 3 Embodiment approach

[0109] Figure 5 It is a plan view showing the curing device according to the third embodiment of the present invention.

[0110] This curing device 21 is the same as the curing device 11 of the second embodiment, and applies an electric field EF to the uncured prepreg 2 (resin composite material) to which the metal nanomaterial 2a is added, and heats it while applying pressure in the thickness direction to make it solidified.

[0111] The curing device 21 is configured to include a flat molding table 22, for example, five pairs of electrodes 23A, 23B to 27A, 27B (environment setting section) facing each other across the prepreg 2 placed on the molding table 22, a pressurizing Body 28, high frequency power supply 15, coaxial cables 16A, 16B and multiple switches 29.

[0112] The five pairs of electrodes 23A, 23B to 27A, 27B are arranged continuously along a predetermined direction (for example, the longitudinal direction) of the prepreg 2 and are connected to the coaxial cab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com