A Method of Using Laser to Process Window

A window and laser technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of not being able to print ink and affect the effect of ink removal, and achieve the goal of not damaging the glass strength, ensuring quality, and improving processing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

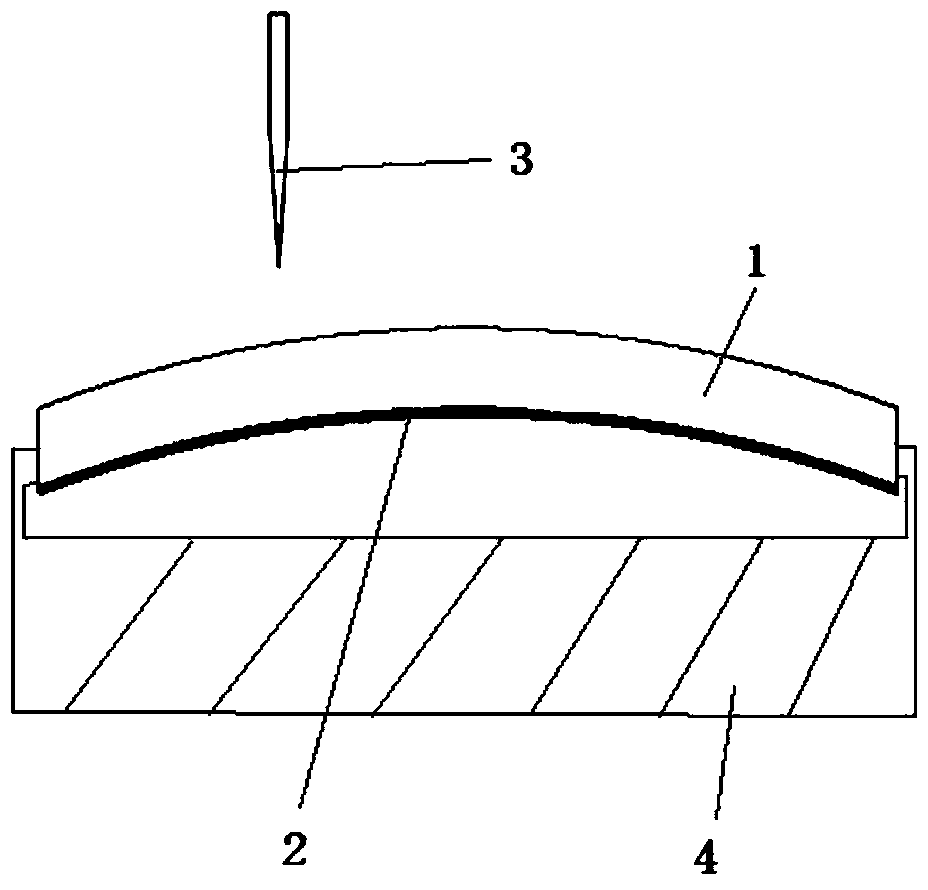

[0027] see figure 1 , Workpiece 1 takes a 3D curved glass screen as an example, using laser to process the window includes the following steps:

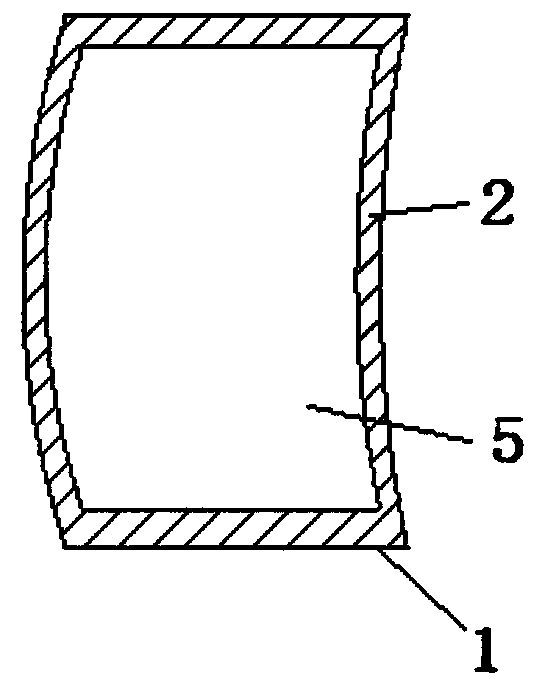

[0028] The first step is to spray the ink layer 2 on the entire surface of the workpiece 1 to be processed (the window processing part and other parts are sprayed at the same time) (it is also possible to paste a protective film on part of the window area to be processed, and then spray ink on the entire surface Layer, the protective film can protect this area from being sprayed with ink layer, after tearing off the protective film, this area does not need to be processed by laser to remove ink, which reduces the area of ink to be removed when laser processing the window);

[0029] The second step is to use a laser to remove the ink layer of the processing part of the window, specifically: the workpiece coated with the ink layer is placed on the fixture 4 with a groove, and the surface of the workpiece coated with the ink layer is ...

Embodiment 2- Embodiment 4

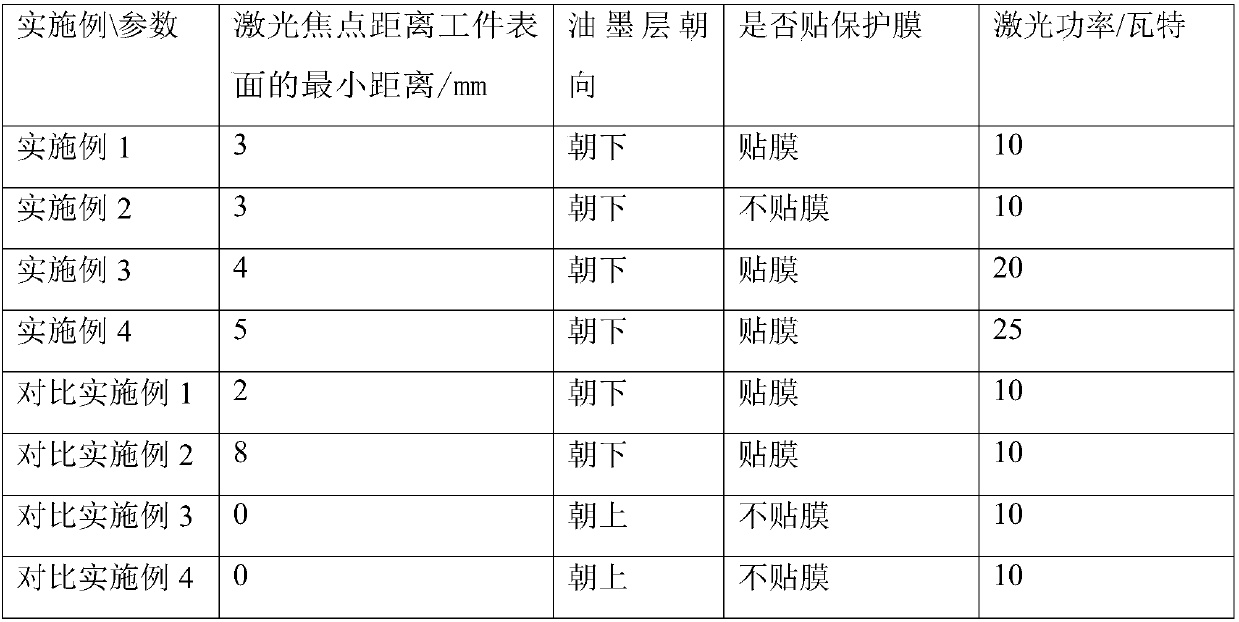

[0037] The difference between embodiment 2-embodiment 4 and embodiment 1 lies in the parameters in Table 1, and the others are the same.

[0038] The properties of the processed products obtained in Examples 2-Example 4 are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com