Automatic feeding equipment for screen printing machines

A screen printing machine, automatic feeding technology, applied in screen printing machine, printing machine, rotary printing machine, etc., can solve the problem of easy paper jam, increase the time and difficulty of installation, complex structure of screen printing machine, etc. problems, to achieve the effect of increasing printing productivity, saving assembly man-hours, and simplifying the number of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

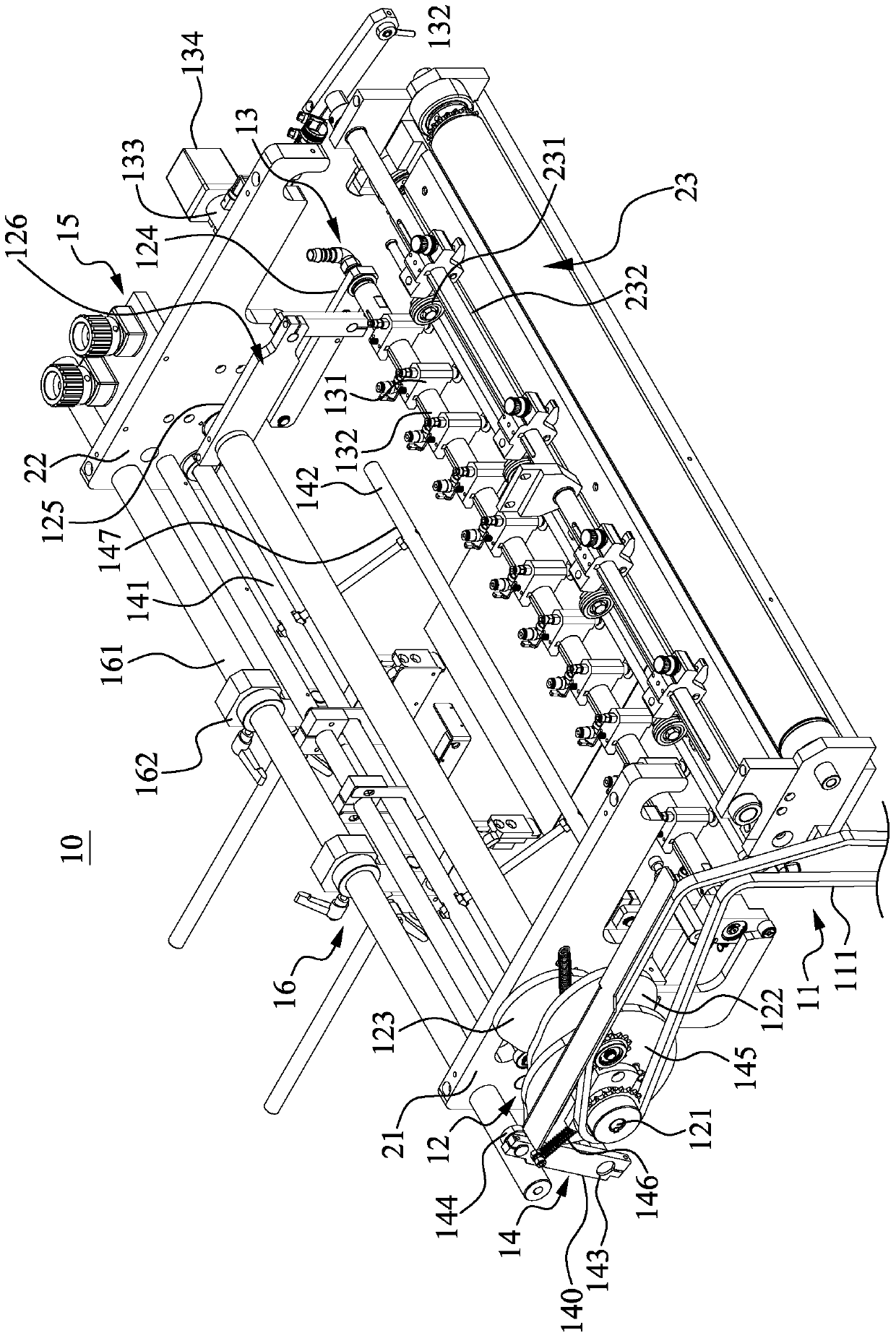

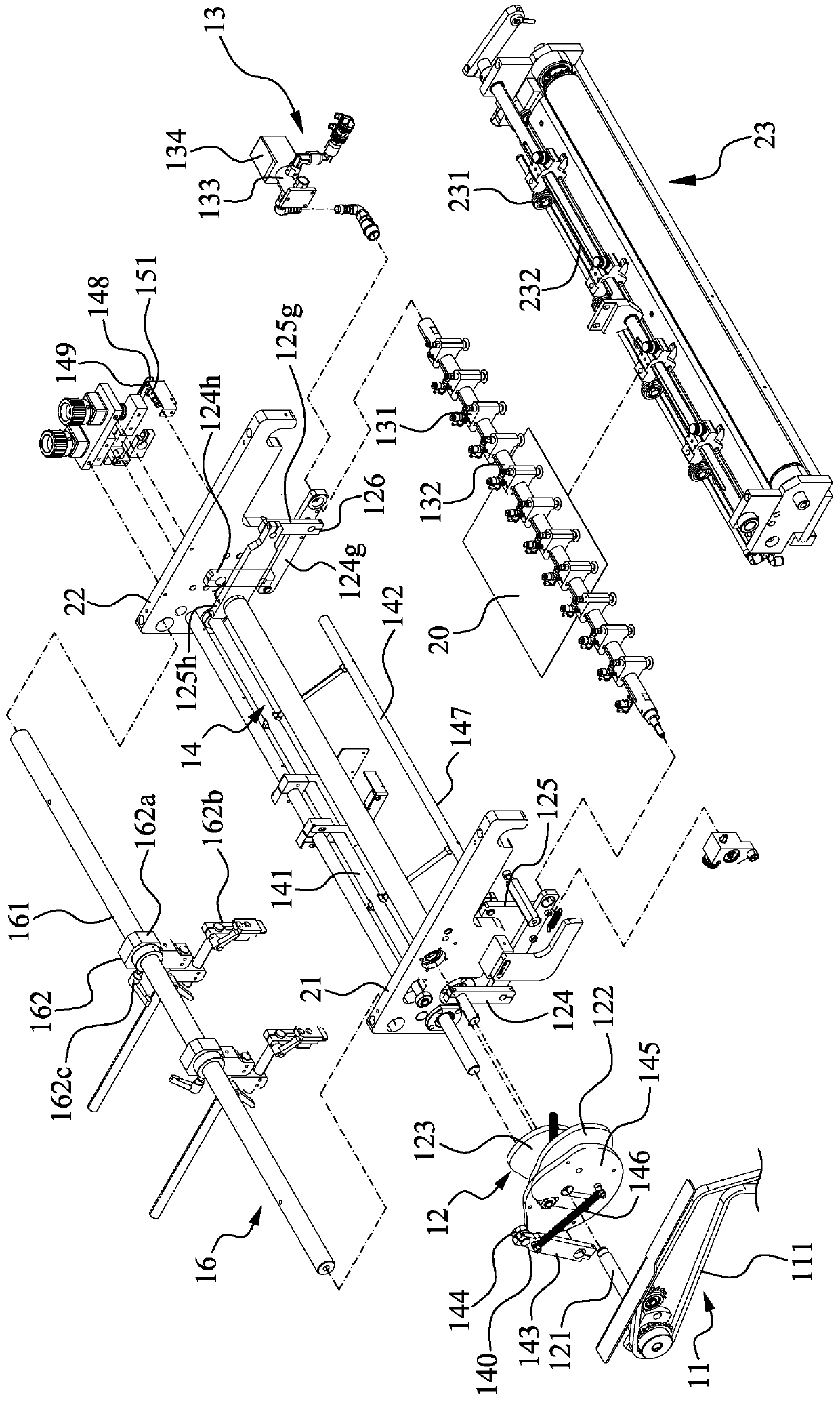

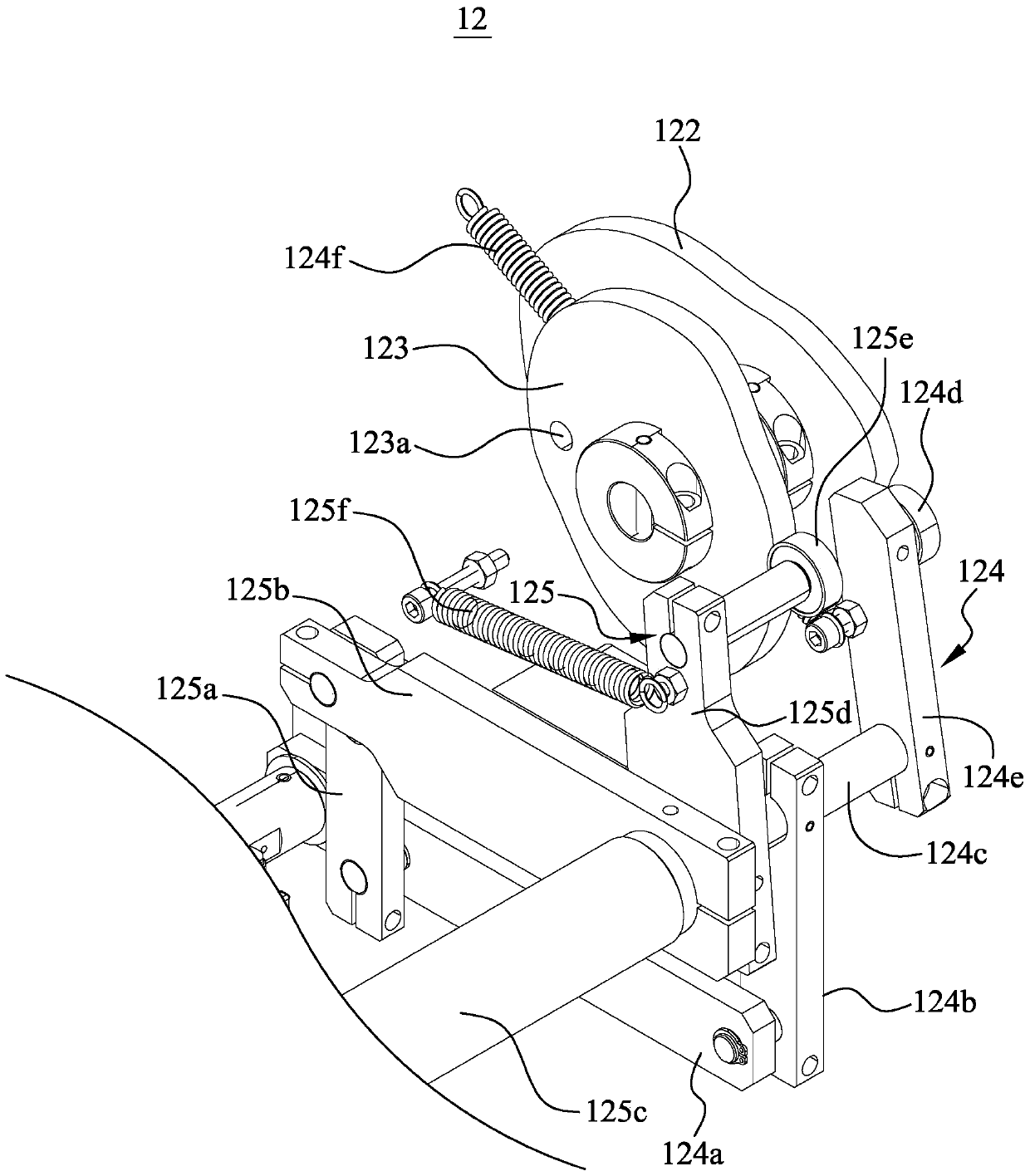

[0030] In order to further have a clearer and more detailed understanding and understanding of the structure, use and features of the present invention, a preferred embodiment is given, and the details are as follows in conjunction with the drawings:

[0031] In this manual, directional words such as front, back, left, right, up, and down mean that the feeding equipment is figure 1 The lower right and upper left directions on the paper, left and right refer to the feeding equipment figure 1 The upper right and lower left directions on the paper, and the upper and lower refers to the feeding equipment in the figure 1 vertical direction of the paper.

[0032] First of all, the automatic feeding equipment 10 of the present invention is mainly to store the initial position 31 of a large number of identical objects from the printed matter 20 (refer to Figure 9 ), the plurality of prints 20 are sequentially transported to a clamped and positioned feeding position 32 by means of a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap