Air blower control circuit with diagnostic function

A technology of control circuit and diagnostic function, which is applied in pump control, mechanical equipment, machine/engine, etc., can solve the problem of high design cost and achieve the effect of saving development cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

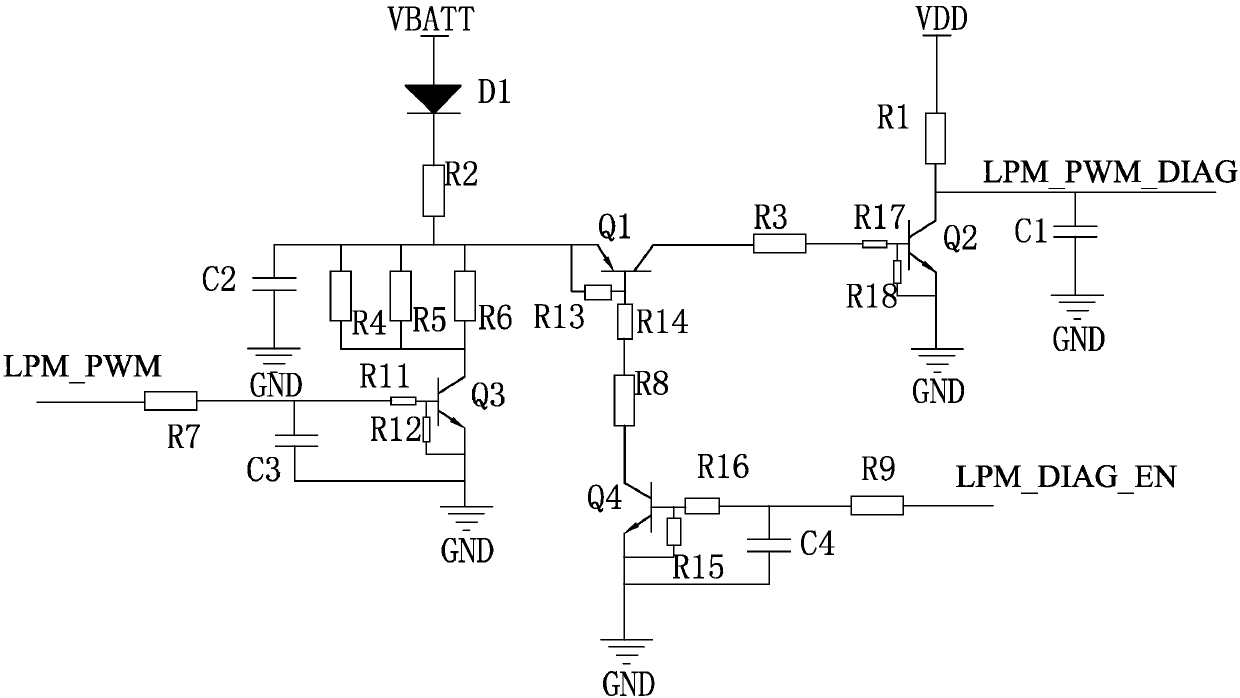

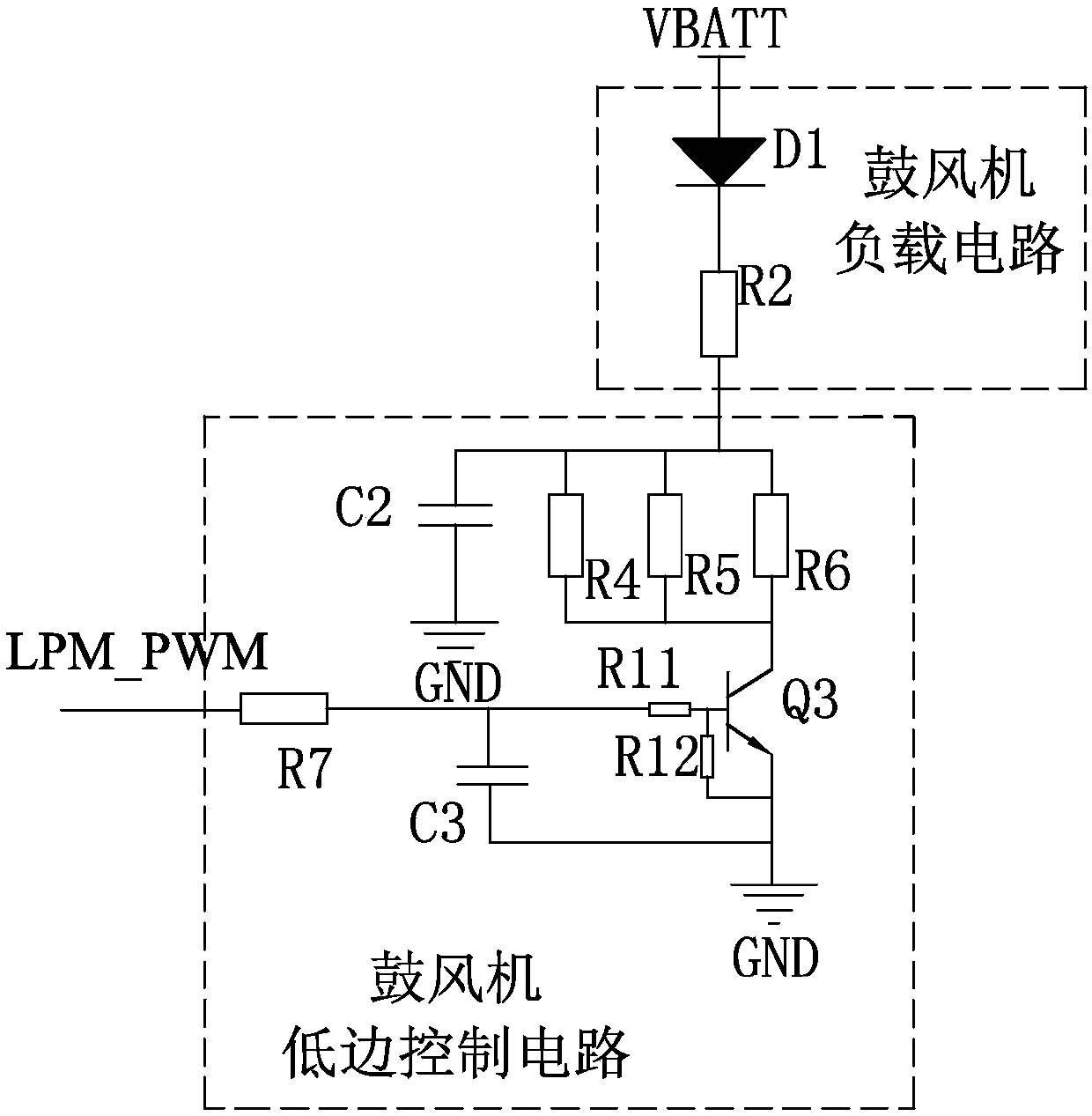

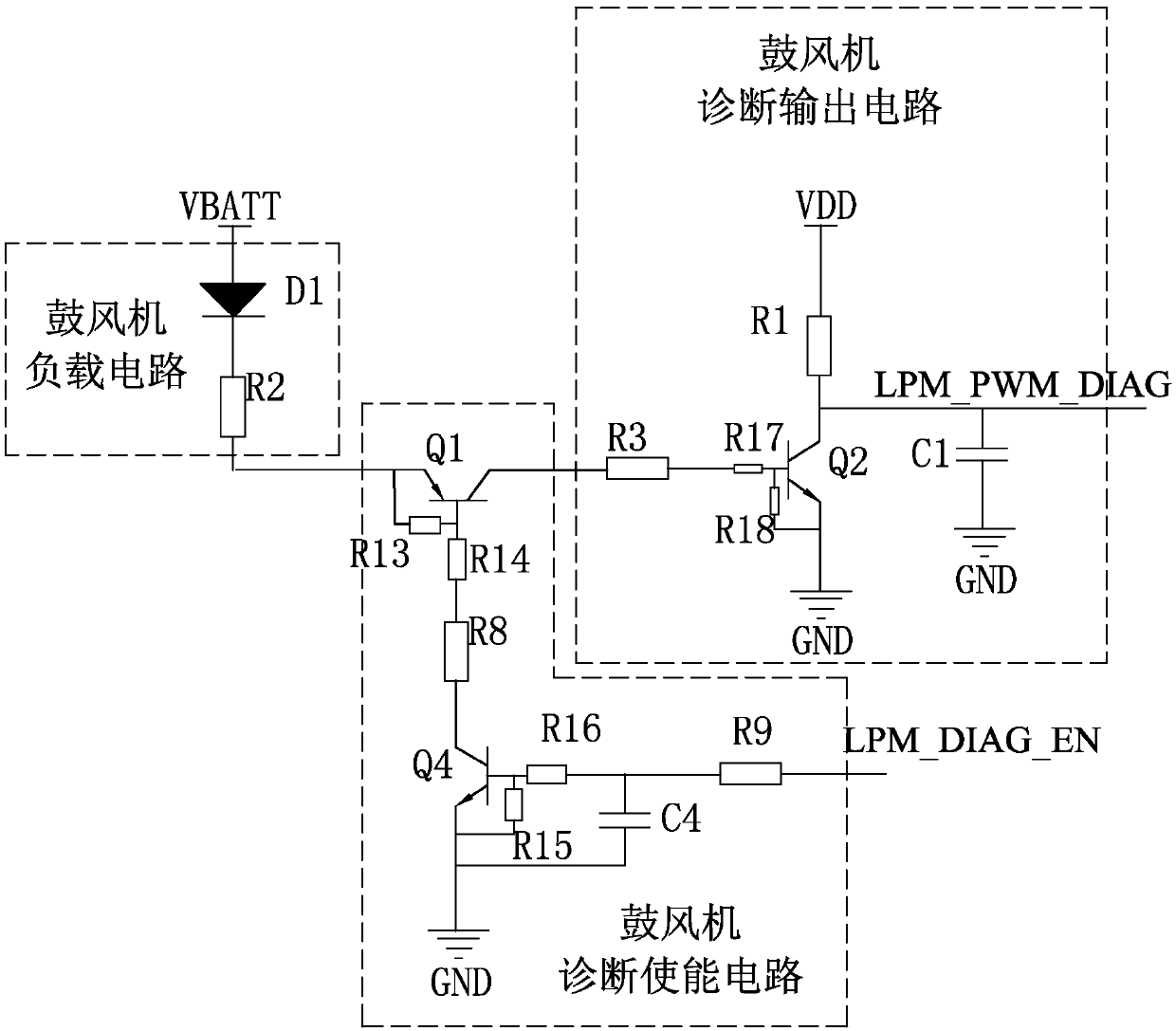

[0016] like Figure 1-3 As shown, the LPM circuit can be divided into: blower external load, blower low-side control circuit and blower diagnostic circuit.

[0017] The blower drive circuit is built with discrete components. The software only needs to control the duty cycle of the LPM_PWM terminal and capture the duty cycle of LPM_PWM_DIAG (requires the corresponding MCU-IO port to have the capture function) to realize the blower output function and the blower output port diagnostic function.

[0018] The working principle of the blower external load circuit:

[0019] The blower load circuit includes power supply voltage VBATT, diode D1 and resistor R2. The anode of diode D1 is connected to the power supply voltage VBATT, and resistor R2 is connected to the cathode of diode D1. The resistance R2 is 4.64KΩ. The type of diode D1 is 1SR154 (maximum positive current 1A).

[0020] Working principle diagram of blower low-side control circuit:

[0021] The blower low-side control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com