Closed main shaft eccentric movement monitoring device and method

A monitoring device and closed technology, applied in measuring/indicating equipment, metal processing equipment, metal processing mechanical parts, etc., can solve problems such as equipment errors, machine tool damage, production accidents, etc. that cannot be eliminated, and achieve high-precision fault monitoring and control. Diagnosis, Overcoming Monitoring Accuracy Problems, Wide Applicable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

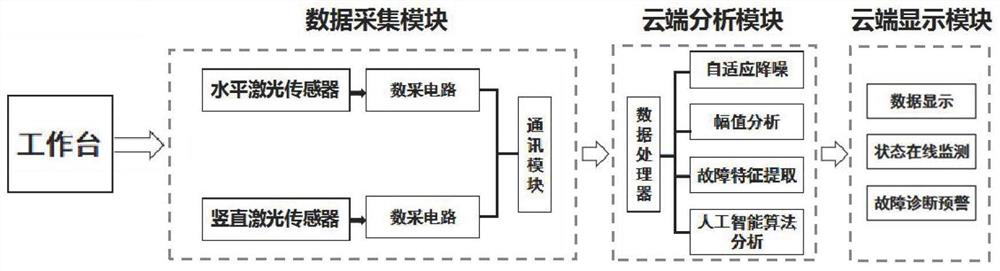

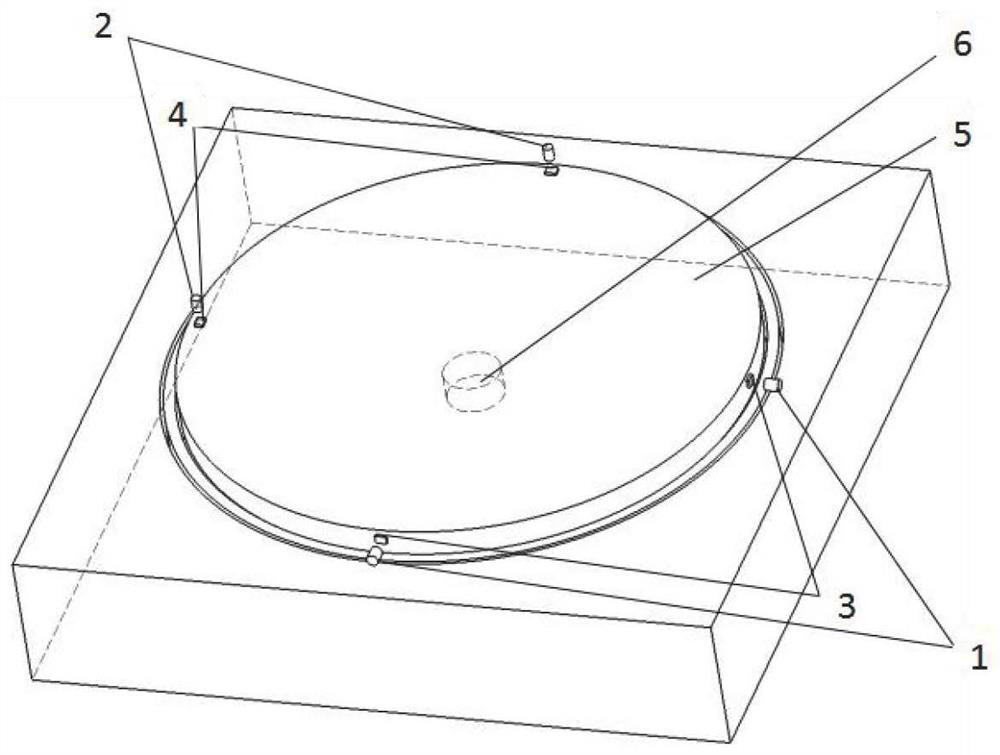

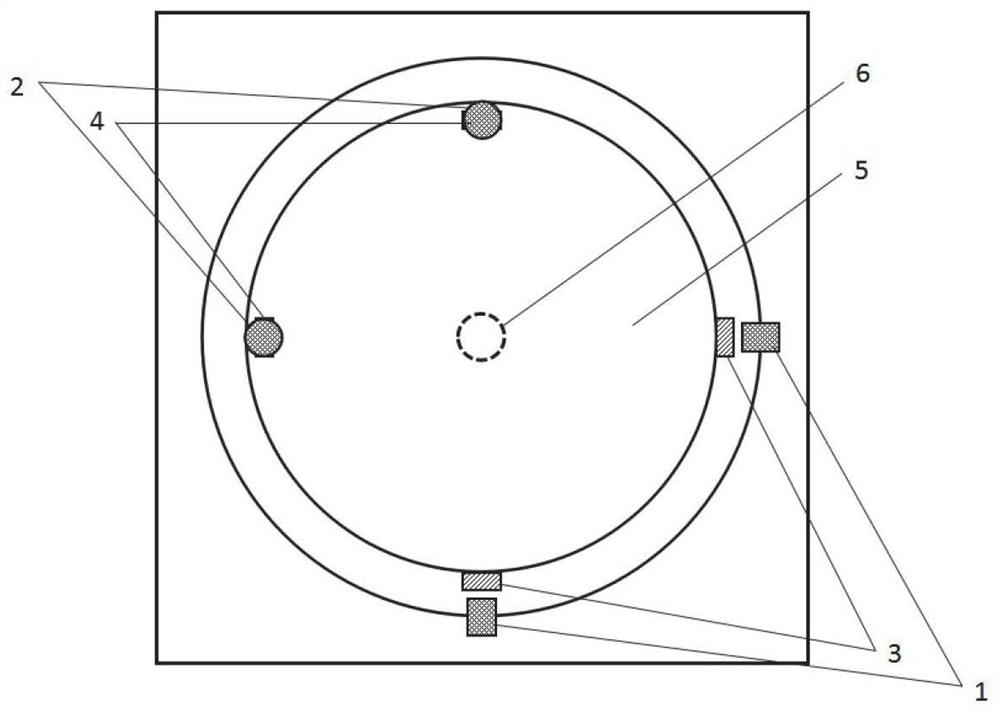

[0034] This embodiment discloses a preferred closed main shaft eccentric movement monitoring device, the monitoring device includes a sensor assembly, a reflector assembly, a data acquisition instrument, a communication module, a cloud analysis module, and a cloud display module;

[0035] The sensor assembly includes a horizontal laser sensor 1 and a vertical laser sensor 2, the reflector assembly includes a horizontal reflector 3 and a vertical reflector 4, and the horizontal laser sensor 1 is arranged on the outer ring of the workbench 5, so The horizontal reflective sheet 3 is arranged at the inner circle of the worktable 5 and corresponding to the horizontal laser sensor 1; the vertical laser sensor 2 is arranged above the upper surface of the worktable 5, and the vertical reflective sheet 4 is arranged on the worktable 5 is arranged on the upper surface and corresponding to the vertical sensor; the worktable 5 is coaxially and fixedly connected to the enclosed main shaft 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com